Vibration reduction type diesel engine tail gas purification device and using method thereof

A technology of exhaust gas purification device and diesel engine, which is applied in the direction of exhaust device, noise reduction device, mechanical equipment, etc. It can solve the problems of troublesome installation and dismantling, inconvenient use, difficult installation and disassembly, etc., and achieve the effect of convenient cleaning in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

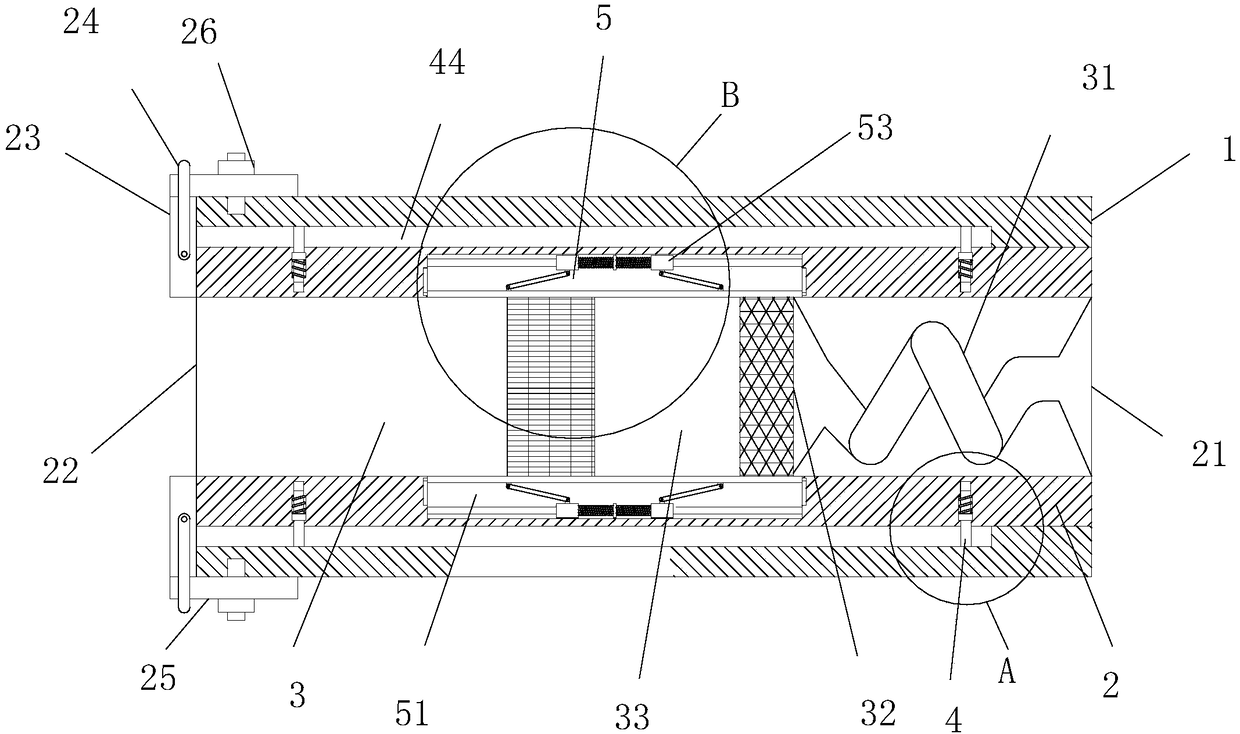

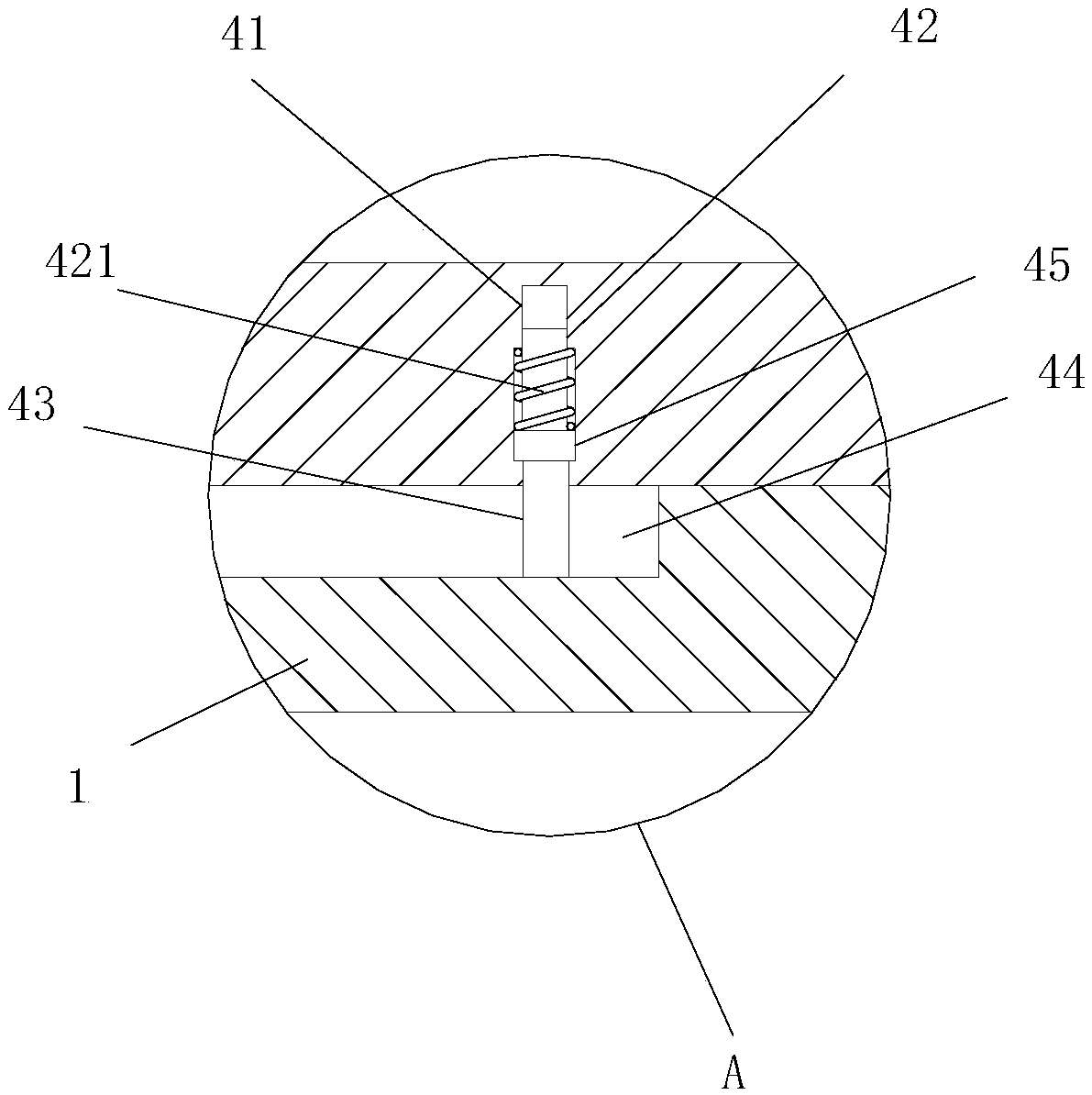

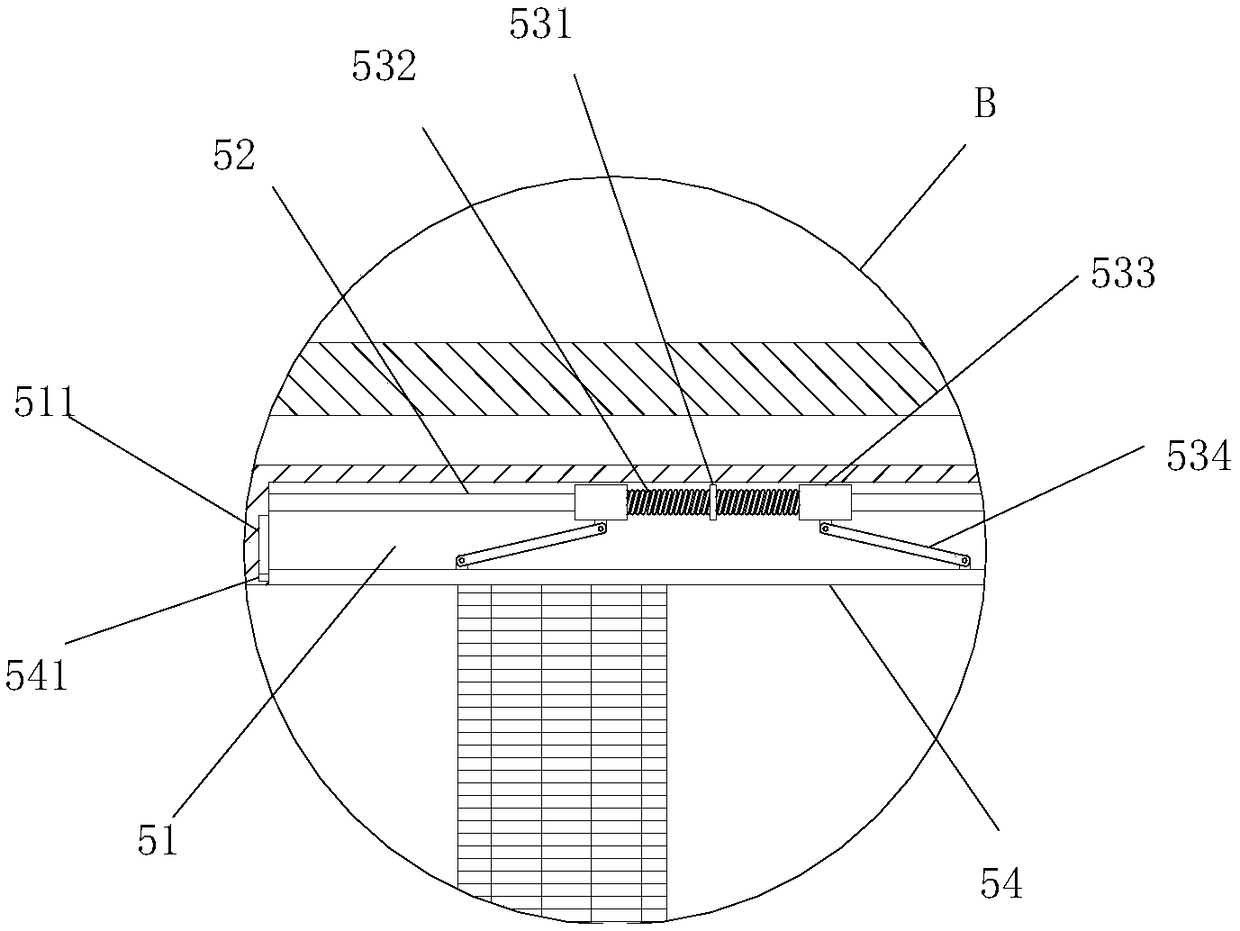

[0032] Such as Figure 1-3 As shown, a shock-absorbing diesel engine exhaust purification device in this embodiment has a simple structure and is easy to use, including an exhaust pipe 1, a housing 2 embedded in the inner circumference of the exhaust pipe 1, a first shock-absorbing system 4 and Second damping system 5.

[0033] The two ends of the housing 2 are respectively provided with an air inlet 21 and an air outlet 22. The inner space of the housing between the air inlet 21 and the air outlet 22 constitutes an air cleaning chamber 3, and the air cleaning chamber 3 is provided with The dust removal pipe 31 connected to the air inlet 21, the filter screen 32 connected to the dust removal pipe 31 and the activated carbon plate 33 connected to the filter screen 32; wherein, the dust removal pipe 31 is in a spiral shape, so that the diesel engine exhaust is generated by the spiral dust removal pipe 31 The centrifugal force removes the solid particles; the activated carbon pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com