Detector self-inspection method, device and medium and radiation type inspection system

A technology of inspection system and self-inspection device, which is applied in the field of radiation imaging, and can solve problems such as inability to detect detector failures in time, inaccurate inspection results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

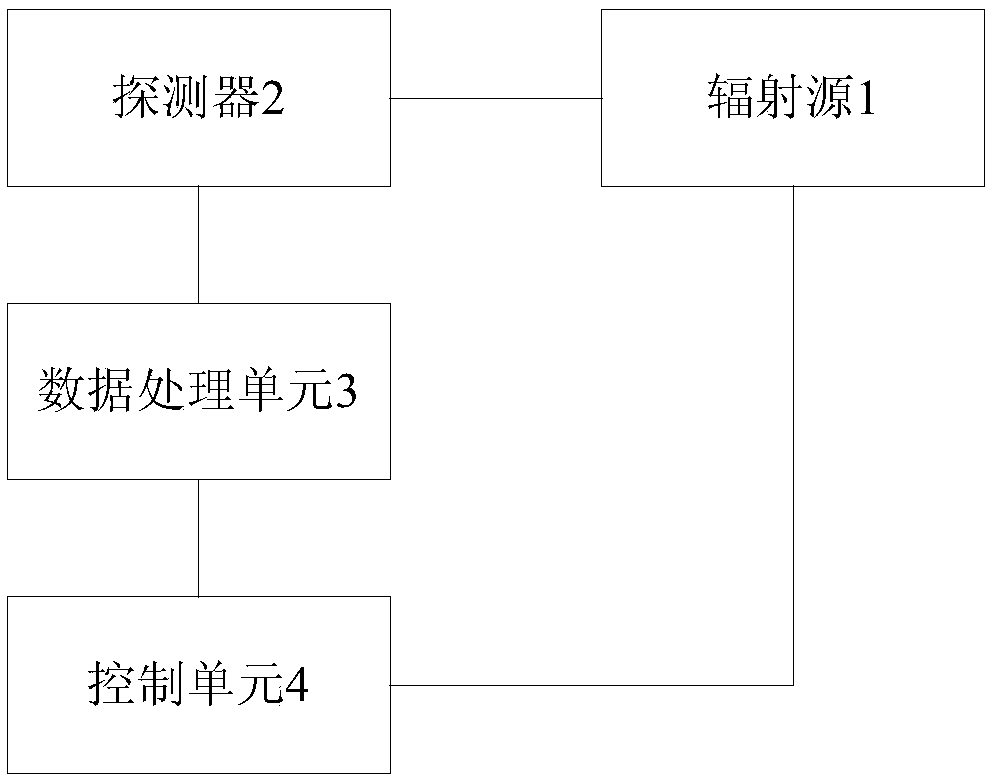

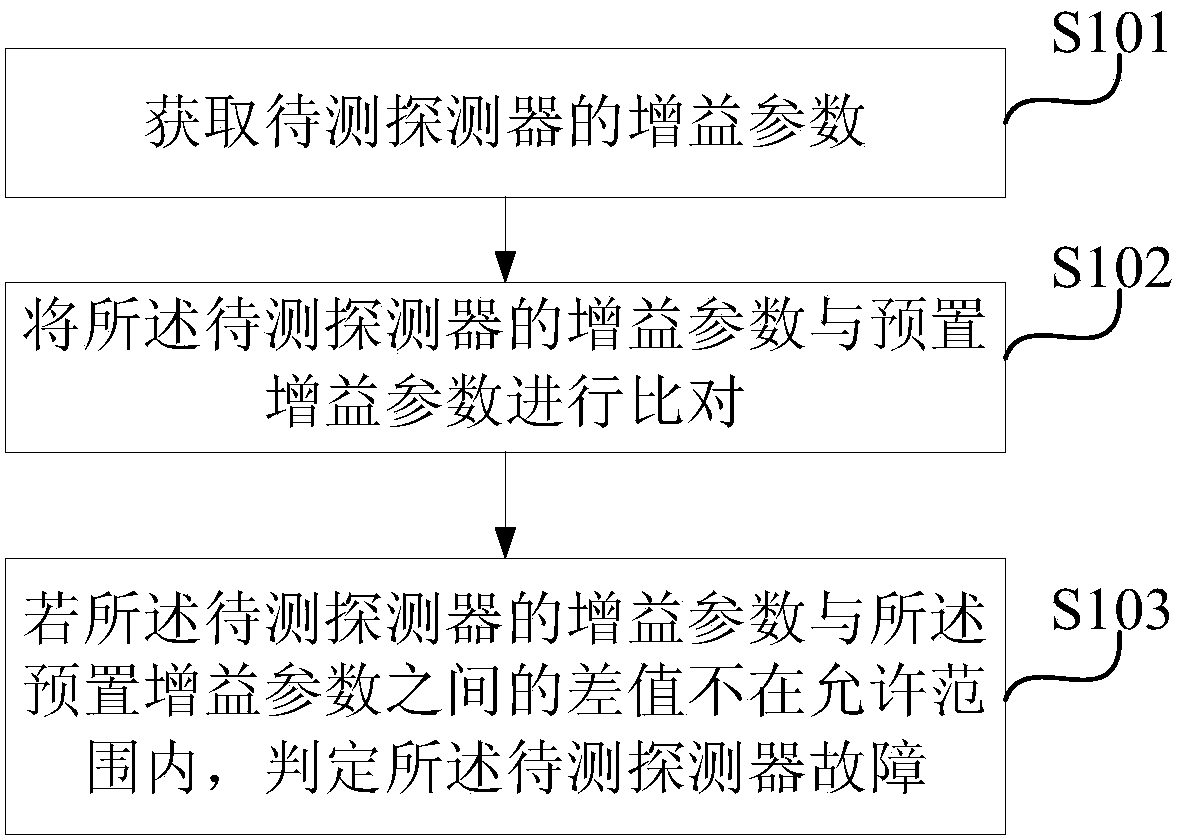

[0081] This embodiment provides a detector self-inspection method, which is applied to the data processing unit of the radiation-type inspection system, and is used for fault detection of the detector in the radiation-type inspection system, such as figure 2 shown, including the following steps:

[0082] S101: Obtain a gain parameter of the detector to be tested. Such as figure 1 As shown, the data processing unit 3 is communicatively connected with the detector 2, and it can obtain the detection data of each pixel in the detector 2, and can obtain the gain parameter of each pixel at the same time. The gain parameter of the detector to be tested in this step may be a list or a matrix including the gain parameter of each pixel.

[0083] S102: Compare the gain parameter of the detector to be tested with a preset gain parameter. The preset gain parameter has been pre-stored in the data processing unit 3, and may be a gain parameter written by the user, or a gain parameter cor...

Embodiment 2

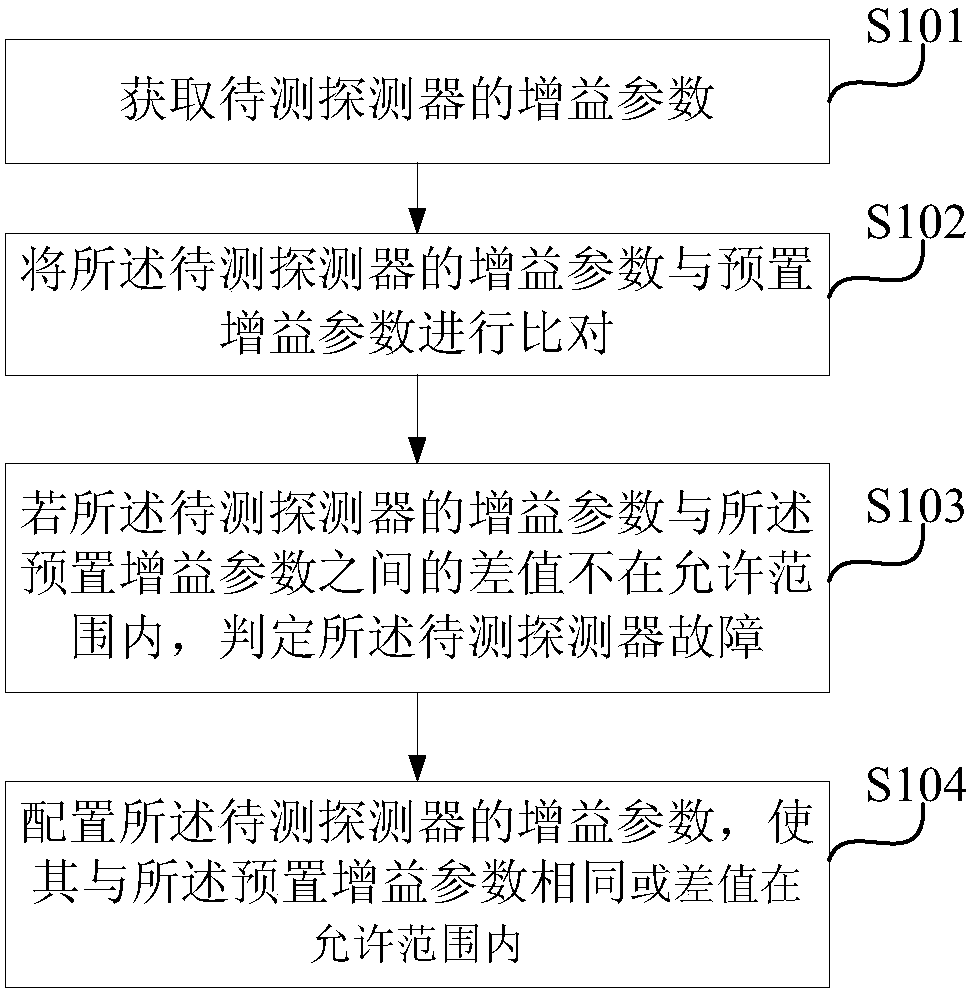

[0088] This embodiment provides a detector self-inspection method, which is applied to the data processing unit of the radiation-type inspection system, and is used for fault detection of the detector in the radiation-type inspection system, such as Figure 4 shown, including the following steps:

[0089] S201: Obtain a gain parameter of the detector to be tested.

[0090] S202: Compare the gain parameter of the detector to be tested with a preset gain parameter, if the difference between the gain parameter of the detector to be tested and the preset gain parameter is not within the allowable range, execute step S205 If the difference between the gain parameter of the detector to be tested and the preset gain parameter is within an allowable range, step S203 is executed.

[0091] S203: Obtain the air value of the detector to be tested, and the air value is measured in the following manner: there is no occlusion between the detector to be measured and the radiation source (the...

Embodiment 3

[0109] As another possible solution, such as Figure 6 shown, including the following steps:

[0110] S301: Obtain a gain parameter of the detector to be tested.

[0111] S302: Compare the gain parameter of the detector to be tested with a preset gain parameter, if the difference between the gain parameter of the detector to be tested and the preset gain parameter is not within the allowable range, execute step S306 If the difference between the gain parameter of the detector to be tested and the preset gain parameter is within an allowable range, step S303 is executed.

[0112] S303: Determine the allowable range of the relative standard deviation of the air value of each pixel in the detector to be tested;

[0113] S304: Obtain the air value of the detector to be tested, which includes the air value of each pixel; the air value is measured in the following manner: there is no obstruction (blocking) between the detector to be tested and the radiation source object generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com