Monitoring and service life managing system for belt conveyor

A belt conveyor and life management technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of less state monitoring information, deviation, tearing, coal piles, overheating, smog, Problems such as motor, gear box, pulley, idler and other parts cannot be repaired, and the effect of improving safety can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the purpose and advantages of the present invention, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

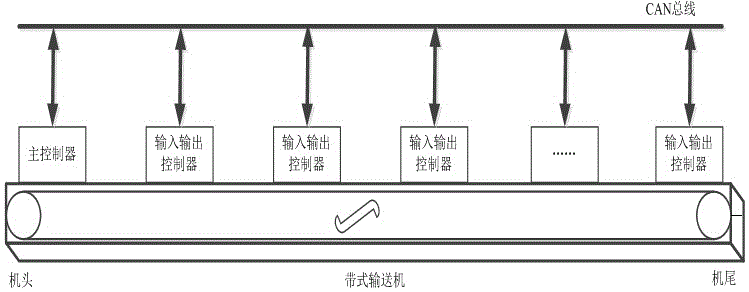

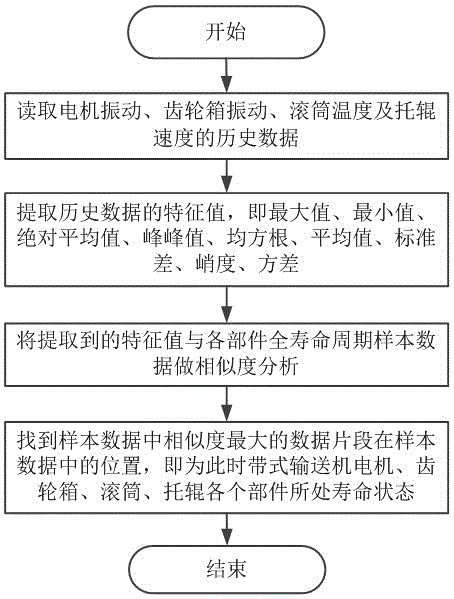

[0019] as attached figure 1 As shown, the implementation of the above-mentioned belt conveyor monitoring and life management system provided by the present invention is based on the prior art, aiming at the belt conveyor under the coal mine to realize the monitoring and life management designed for automatic mining system, the belt conveyor monitoring and life management system mainly includes a main controller and a plurality of input and output controllers, and the main controller realizes comprehensive monitoring and motor control of the belt conveyor through the plurality of input and output controllers , gear box, pulley, idler life management of each component.

[0020] In the specific implementation above, the main controller c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com