Gas valve part numerical control machining automatic programming system

A technology of automatic programming and parts, applied in general control system, control/adjustment system, program control, etc., can solve the problems of high price and poor professionalism of commercial CAM software, reduce debugging man-hours, high accuracy rate, and improve system efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

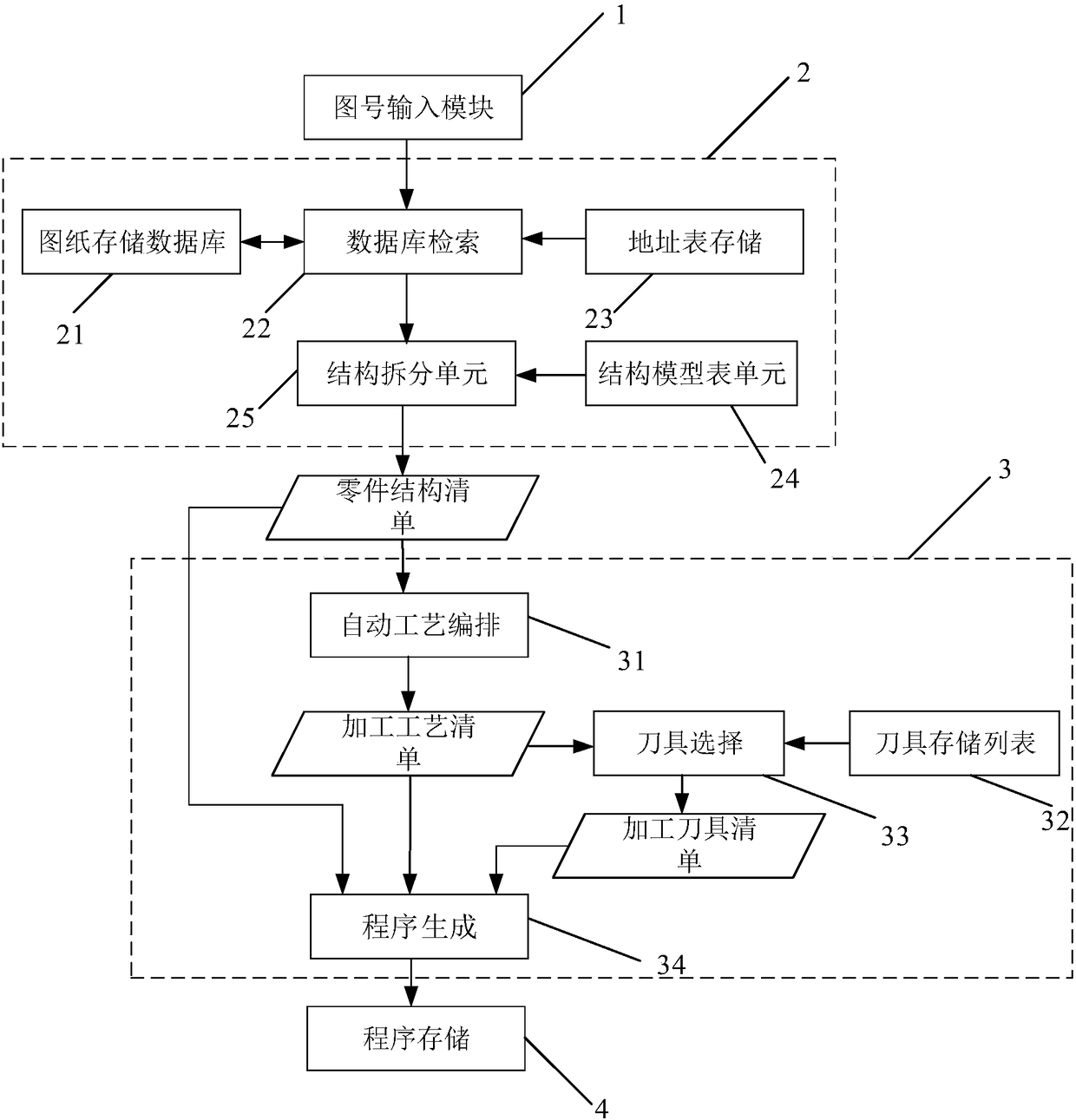

[0046] Such as figure 1 As shown, an automatic programming system for CNC machining of air valve parts, the system includes:

[0047] Drawing number input module 1: This module is used to input the drawing number of the valve parts to be processed;

[0048] Automatic data retrieval module 2: This module retrieves the input drawing number to obtain the part structure list of the valve parts to be processed;

[0049] Program automatic programming module 3: This module arranges the processing technology and selects the tool according to the part structure list, and then generates the CNC machining control program;

[0050] Program storage module 4: This module is used to store the generated NC machining control program.

[0051] Automatic Data Retrieval Module 2 includes:

[0052] Drawing storage database sub-module 21: this sub-module stores the drawings of air valve parts;

[0053] Database retrieval sub-module 22: This sub-module looks up the drawing of the corresponding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com