Hot rolling slab yard two-crane-spanning automatic control method

A slab and driving technology, which is applied in the direction of non-electric variable control, vehicle position/route/height control, control/adjustment system, etc., can solve the problems of increased labor intensity, low driving operation efficiency, and manual intervention, etc., to achieve reduction The effect of reducing the labor intensity of personnel and improving the overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

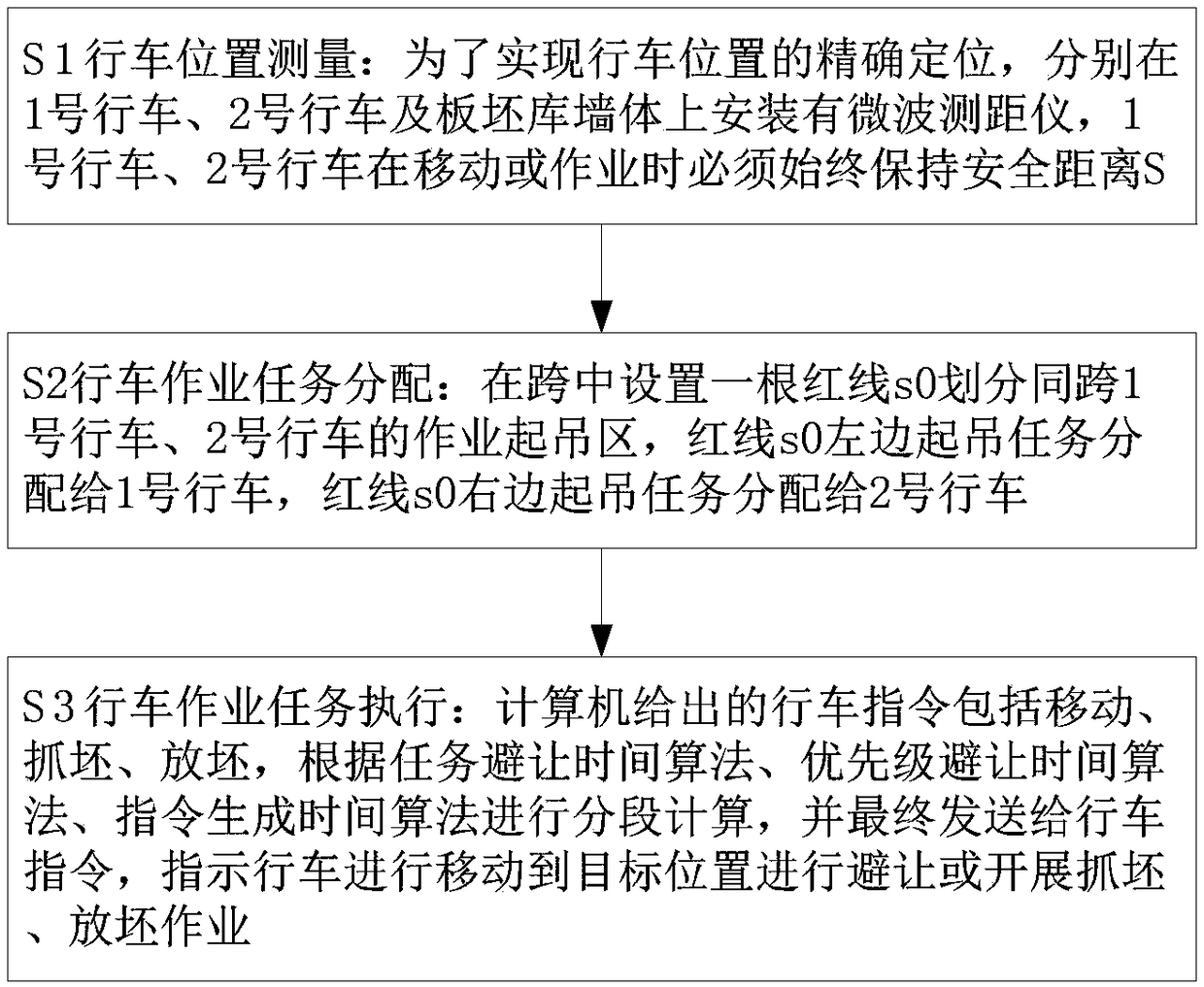

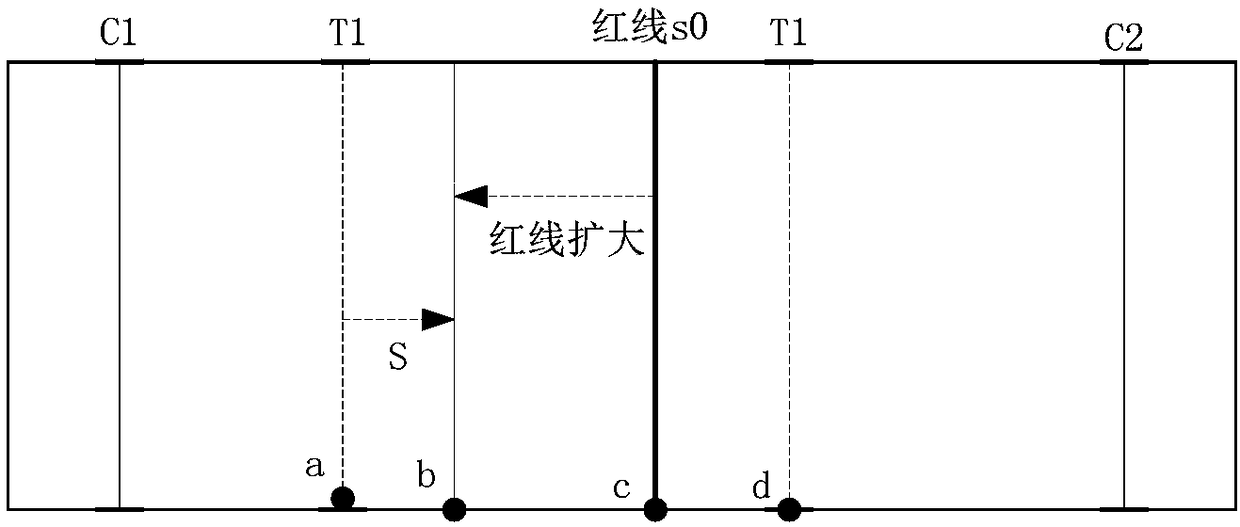

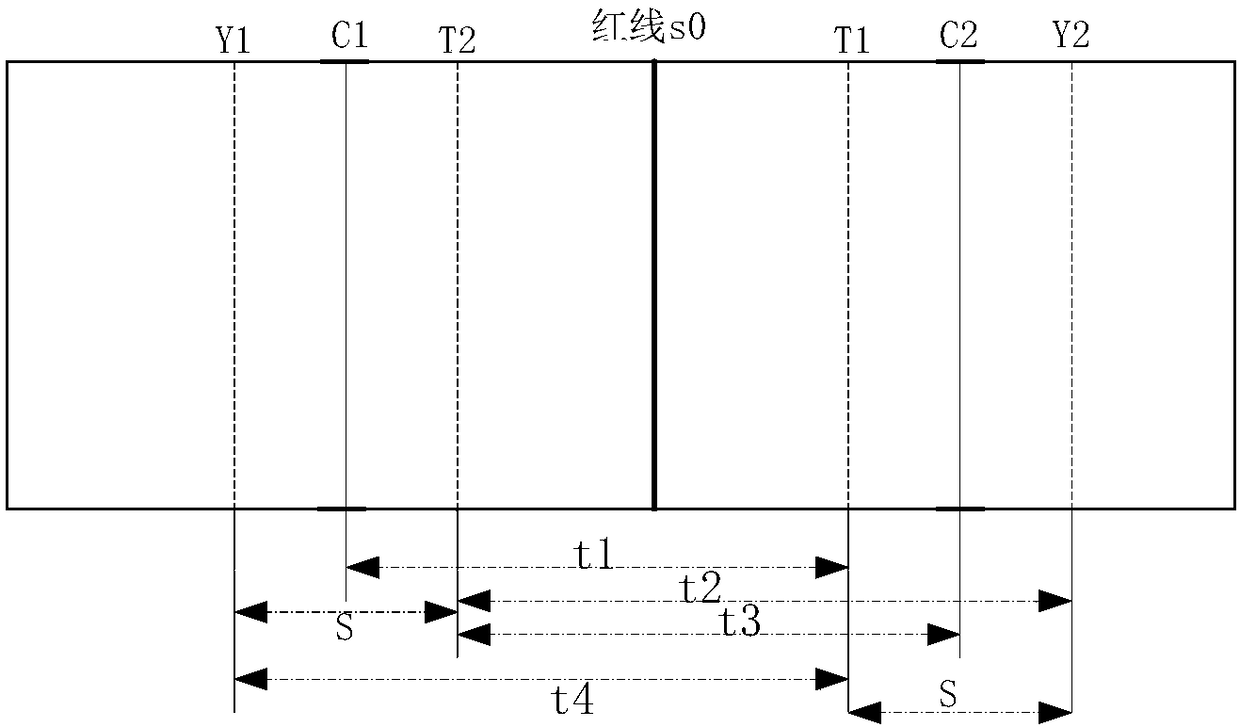

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content and advantages of the technical solution of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings.

[0027] The logistics of the hot-rolled slab warehouse is extremely complicated. It is necessary to ensure the timely storage of slabs from different sources and different attributes and balance the requirements of the steel loading rhythm of the rolling line. Therefore, the management of the slab warehouse plays a key role in the hot-rolled production organization. , and the rationality of stacking slabs is the core. Taking the slab warehouse of a steel factory as an example, the warehouse is divided into three spans (S1, S2, S3), which are vertically arranged with the main rolling line. A total of 6 cranes are configured in the warehouse area, and the ground equipment mainly includes M roller table, L roller table, A roller table, 3 cross-span trolleys, slab conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com