Double-locking-sleeve curved bar neck yoke

A lock sleeve and pillory technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of increased damage rate of pillory, troublesome operation, laborious adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

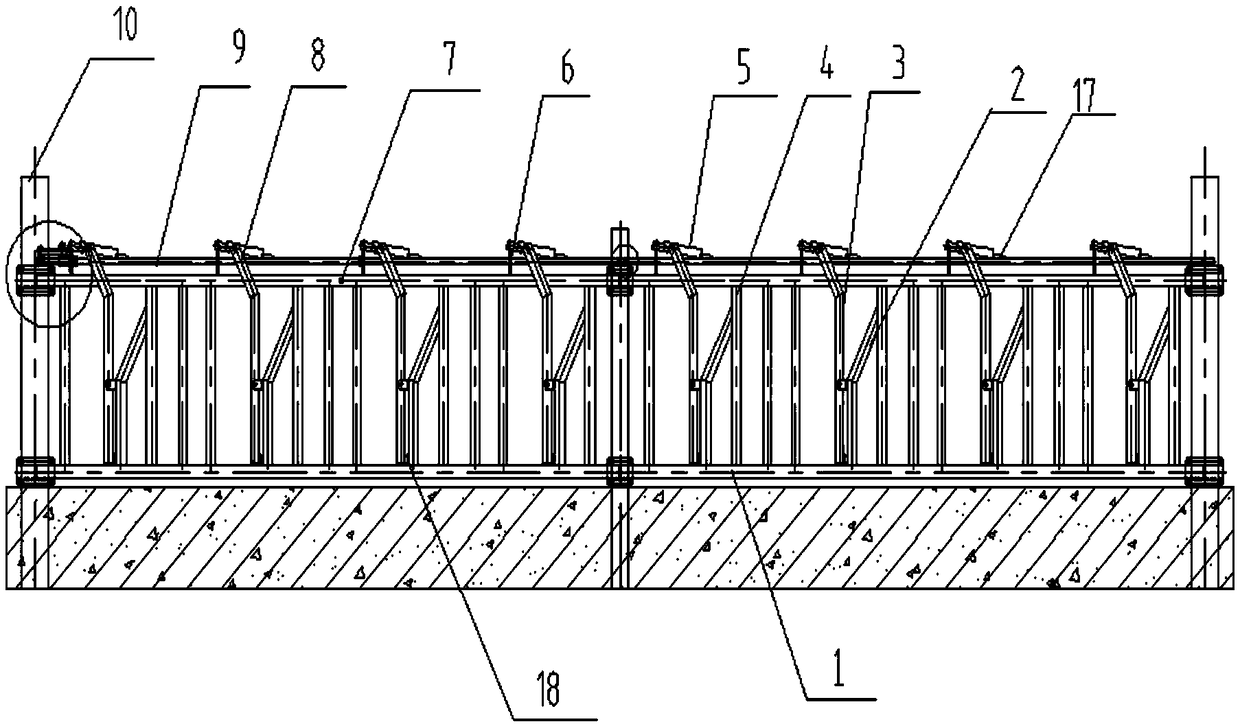

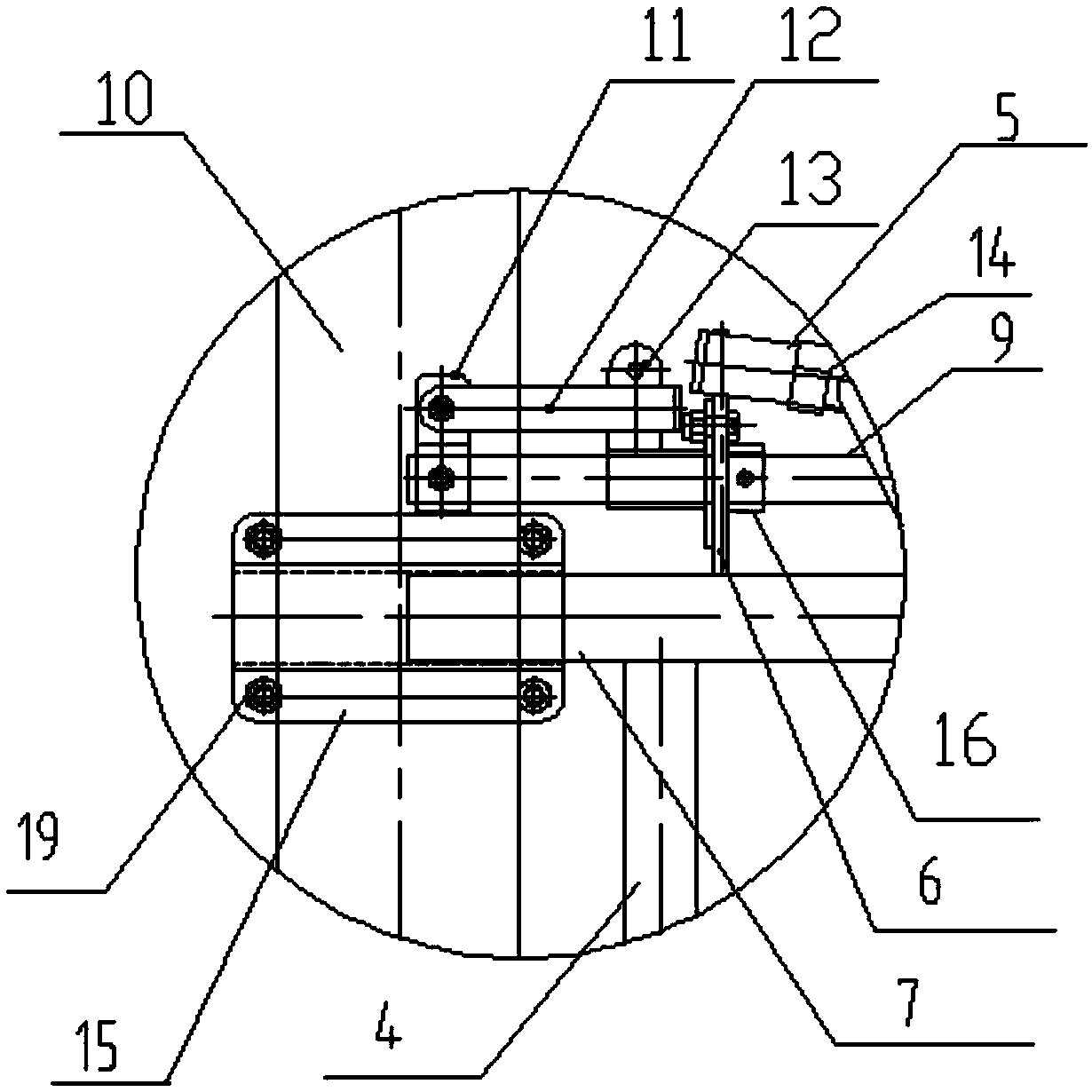

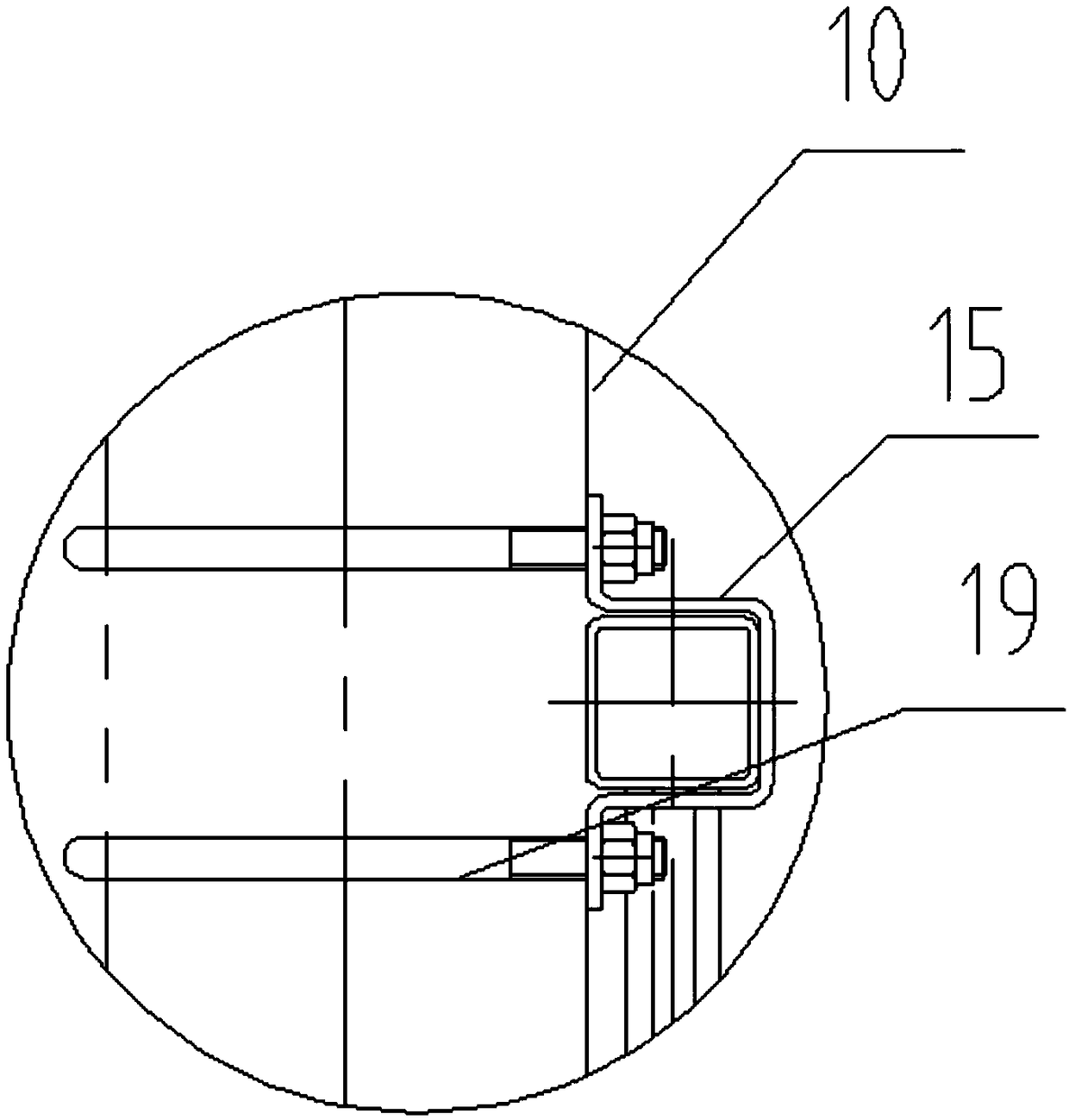

[0020] A kind of double lock sleeve curved rod pillory, which includes a pillory body and a double lock sleeve mechanism, and the pillory body includes an upper cross bar 7, a lower cross bar 1 and a plurality of Bending bar 2, vertical bar 4, movable pendulum bar 3, described vertical bar is fixedly connected with upper horizontal bar and lower horizontal bar respectively, and bending bar is arranged between two vertical bars, and the bottom of bending bar and The lower horizontal bar is fixedly connected, the top is fixedly connected with the vertical bar on the bending side, and the bending part of the bending bar is hinged with a movable swing bar. The movable swing bar includes a lower swing bar and an upper inclined swing bar. The double lock sleeve The mechanism includes a first lock sleeve 8 fixedly installed on the top of the movable swing rod and a second lock sleeve 5 hinged to the upper part of the first lock sleeve. A plurality of lock sleeve limit plates 6 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com