Assembly structure for dust collector and dust collector

An assembly structure and vacuum cleaner technology, applied in vacuum cleaners, applications, household appliances, etc., can solve the problems of complex disassembly and assembly procedures, and achieve the effects of improving user experience, simplifying disassembly and installation procedures, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

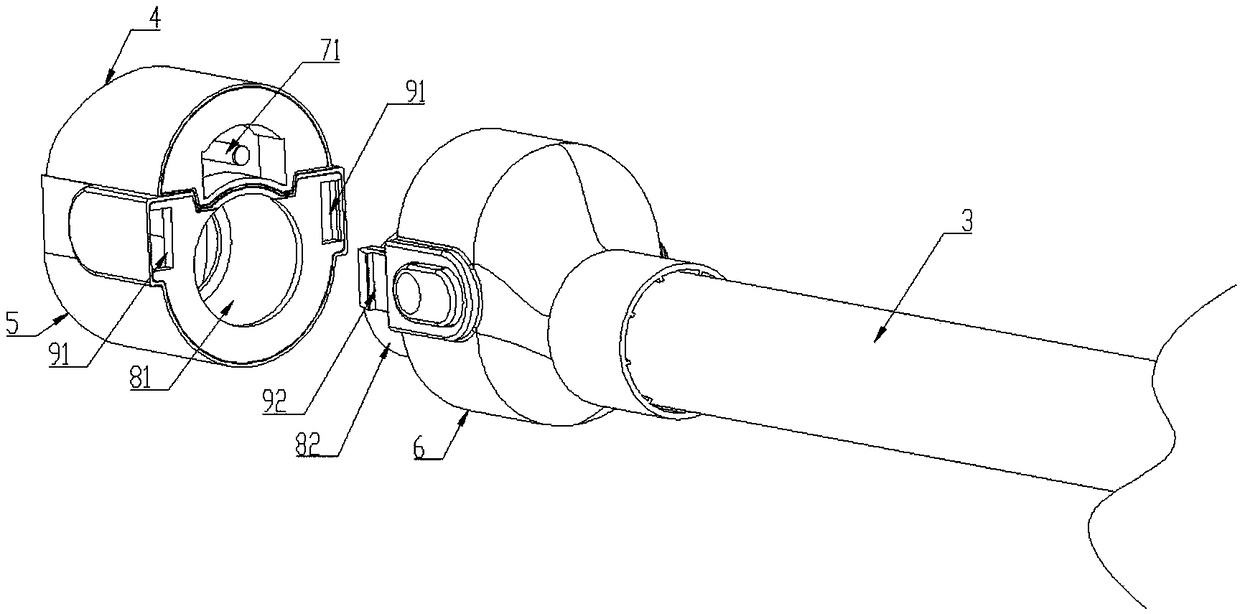

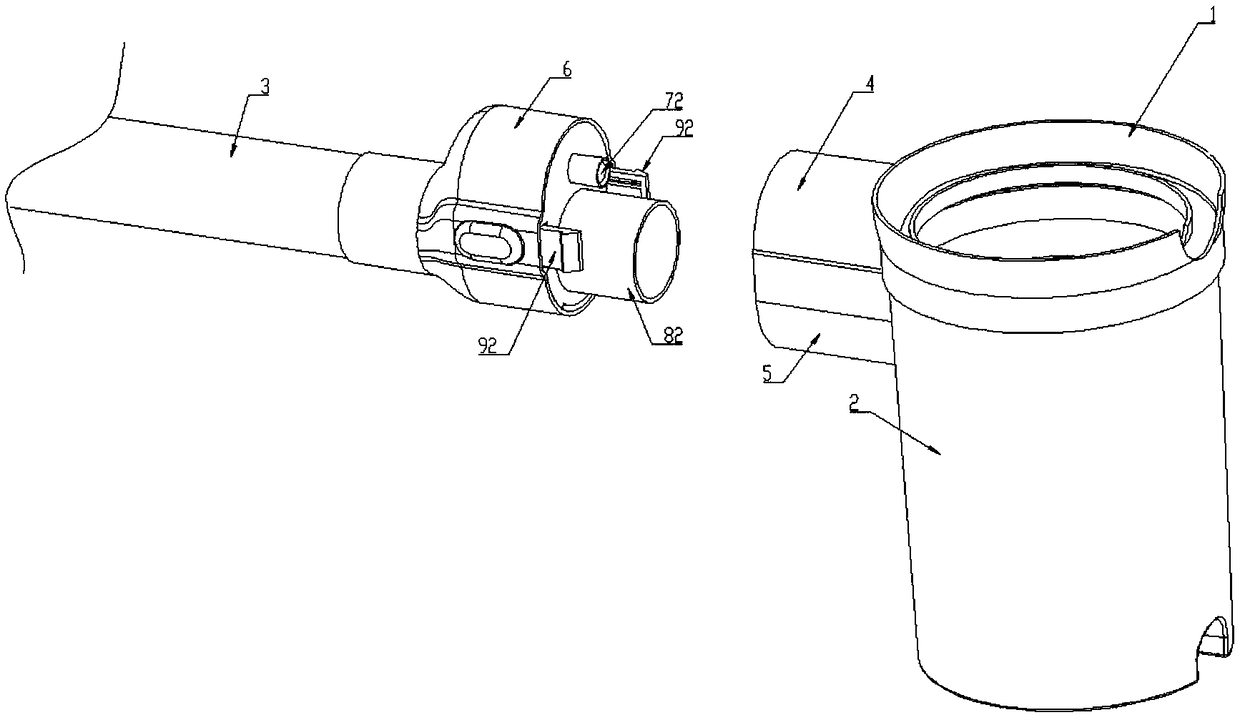

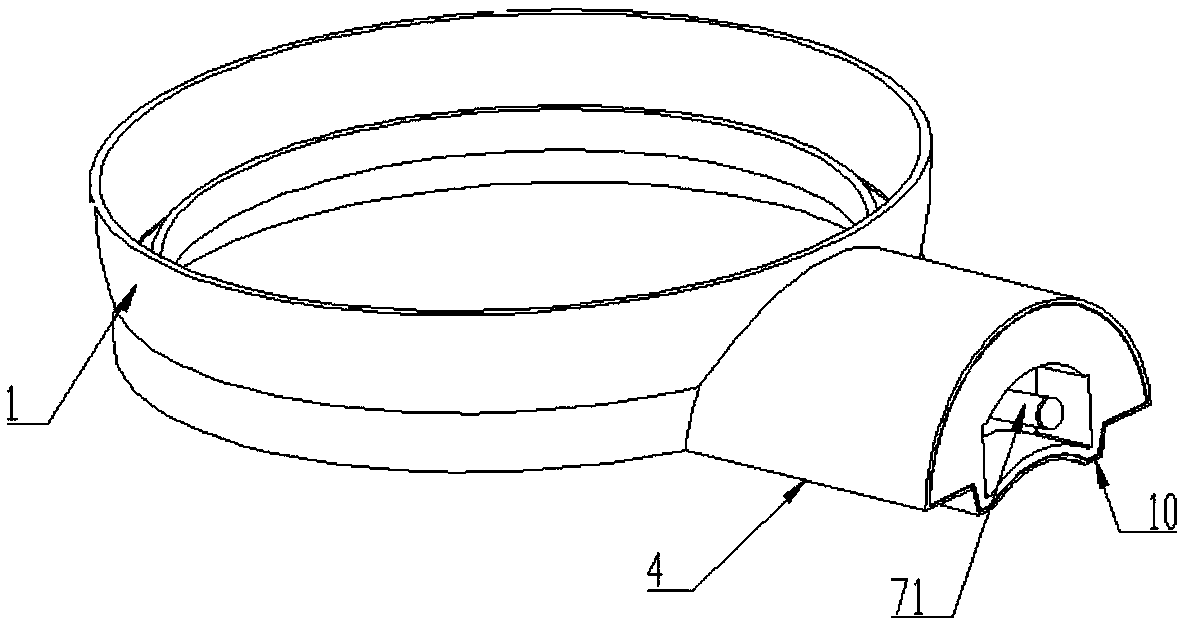

[0049] Such as Figure 1 to Figure 4 As shown, it is Embodiment 1 of the present invention. This embodiment provides an assembly structure applied to a vacuum cleaner. As described in the background technology, the dust cup 2 of the vacuum cleaner in the prior art is disassembled and installed. Too complicated, the assembly structure provided by this embodiment can effectively solve the above problems and simplify the disassembly and installation procedures of the dust cup 2 .

[0050] This embodiment includes an upper joint 4, a lower joint 5 and a pipe joint 6, the upper joint 4 is arranged on the separation device 1 of the vacuum cleaner; the lower joint 5 is arranged on the dust cup 2 of the vacuum cleaner; the pipe joint 6 is arranged on the air inlet pipe 3 of the vacuum cleaner One end where the upper airflow flows out; the upper joint 4 and the lower joint 5 are detachably connected to the pipe joint 6 at the same time, and can keep the relative position unchanged unde...

Embodiment 2

[0061] This embodiment is a vacuum cleaner, which includes an air inlet pipe 3, a dust cup 2 and a separation device 1. The separation device 1 is installed in the shape of a cover at the mouth of the dust cup 2, and the side wall of the dust cup 2 communicates with the air inlet pipe 3. . The dust cup 2, the air inlet pipe 3 and the separation device 1 are installed together through the assembly structure in the first embodiment.

[0062] Since this embodiment includes the assembly structure in embodiment 1, it also has all the technical effects brought by the assembly structure in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com