Degradable material for disposable uterine probe

A technology for degrading materials and probes, applied in medical science, surgery, etc., can solve problems such as damage to human health, large usage, inability to combine degradation, corrosion resistance and antibacterial at the same time, and achieve good compatibility and degradation performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

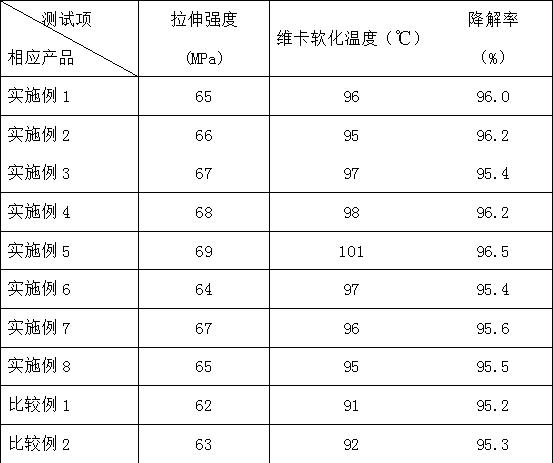

Examples

Embodiment 1

[0018] The degradable material used for the uterine probe in this embodiment includes parts by weight of the following components:

[0019] Glycidyl methacrylate grafted poly-L-lactic acid: 78; polycaprolactone: 25; lubricant ethylene bisstearamide: 3.0; modifier with core-shell structure: 4.0, the shell of the modifier It is a mixture of poly D-lactic acid and polyisoprene, here, the mass ratio of poly D-lactic acid and polyisoprene is 1:3, the core layer is sodium alginate and oligomeric chitosan, and alginic acid Sodium accounts for 4.0% of the mass of the modifier; oligochitosan accounts for 0.5% of the mass of the modifier, and the molecular weight of the oligochitosan is 5000Da.

[0020] The manufacturing method of the disposable uterine probe can be processed by conventional methods in the art, and the specific preparation method in this embodiment is as follows:

[0021] Select the raw materials according to the weight ratio of the ingredients in the above formula, ad...

Embodiment 2

[0023] The degradable material used for the uterine probe in this embodiment includes parts by weight of the following components:

[0024] Glycidyl methacrylate grafted poly-L-lactic acid: 75; polycaprolactone: 25; lubricant ethylene bisstearamide: 4.0; modifier with core-shell structure: 5.0, shell layer of modifier It is a mixture of poly D-lactic acid and polyisoprene, here, the mass ratio of poly D-lactic acid and polyisoprene is 1:3.5, the core layer is sodium alginate and oligomeric chitosan, and alginic acid Sodium accounts for 6.0% of the mass of the modifier; oligochitosan accounts for 0.8% of the mass of the modifier, and the molecular weight of the oligochitosan is 6000Da.

[0025] The manufacturing method of the disposable uterine probe is consistent with that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0027] The degradable material used for the uterine probe in this embodiment includes parts by weight of the following components:

[0028] Glycidyl methacrylate grafted poly-L-lactic acid: 76; polycaprolactone: 23; lubricant ethylene bisstearamide: 35; modifier with core-shell structure: 4.5, the shell layer of the modifier It is a mixture of poly D-lactic acid and polyisoprene, here, the mass ratio of poly D-lactic acid and polyisoprene is 1:3, the core layer is sodium alginate and oligomeric chitosan, and alginic acid Sodium accounts for 5.0% of the mass of the modifier; oligochitosan accounts for 0.6% of the mass of the modifier, and the molecular weight of the oligochitosan is 5500Da.

[0029] The manufacturing method of the disposable uterine probe is consistent with that of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com