Boring-milling machining method of high-precision semicircular hole group

A technology for boring and milling processing and semi-circular holes, which is applied in the field of boring and milling processing of high-precision semi-circular hole groups, can solve problems such as low survival rate of parts, achieve reasonable and stable contact stress, optimize rough and finish machining allowance, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

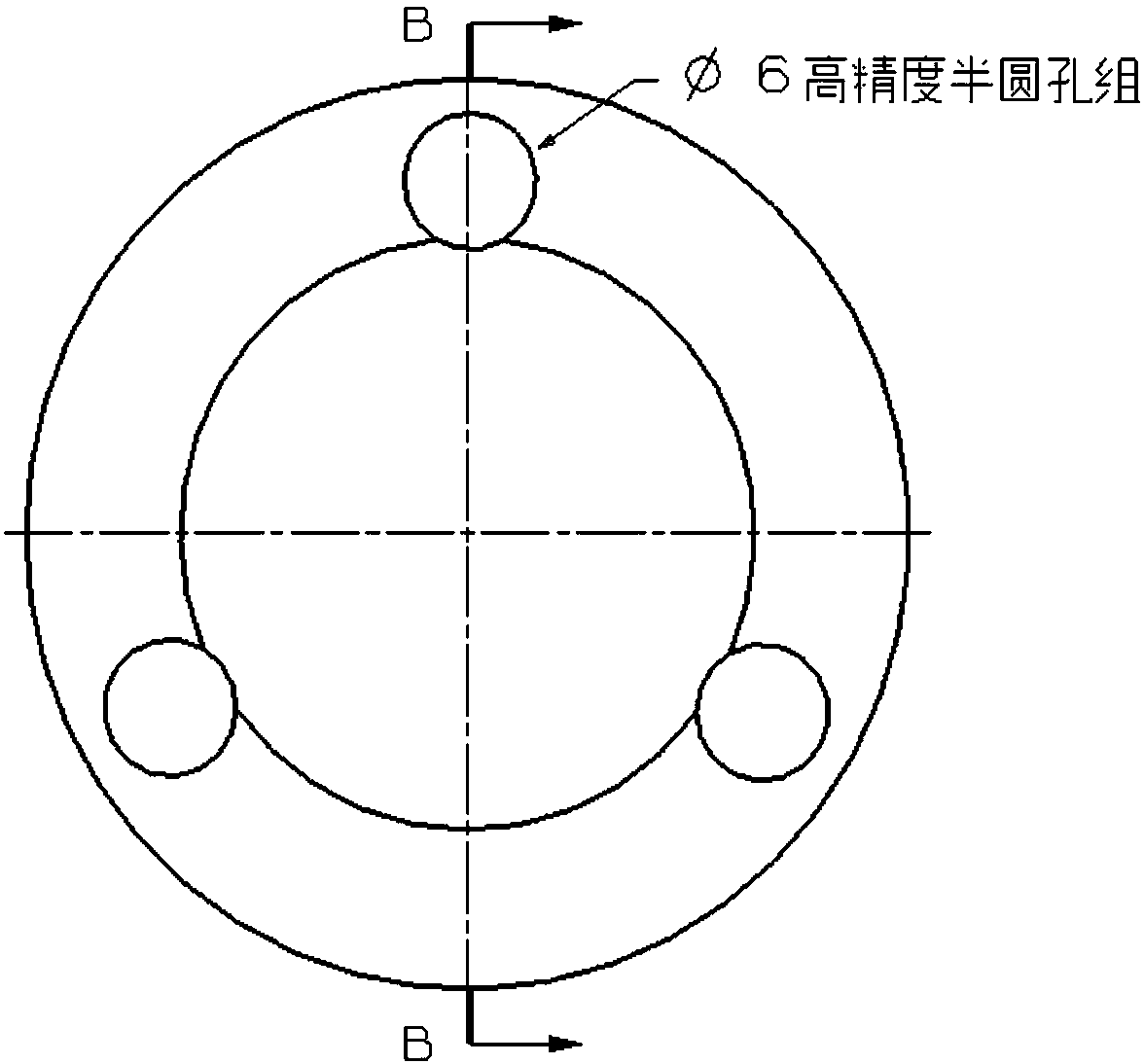

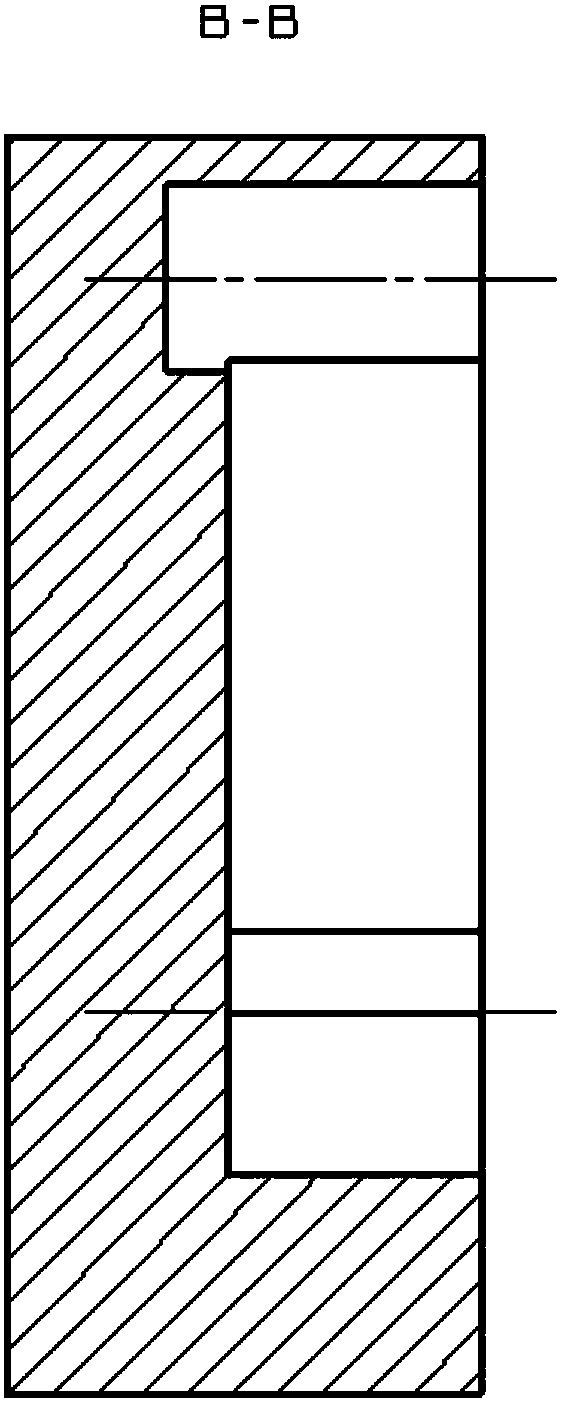

[0031] The material of an output shaft part is 15-5PH stainless steel, and the diameter of the semicircular hole group is mm, the diameter dimension of the central hole intersecting it is Machining on a three-axis CNC machine, combined with attached figure 1 The specific processing process is as follows:

[0032] 1) Reasonably arrange the rough and finish machining processes. The rough, semi-finish and finishing processes in the whole process are drilling, milling, boring and reaming in sequence. Heat treatment stress relief processes are added between the drilling and milling processes and between the milling and boring processes.

[0033] 2) Optimize roughing and finishing allowance. Rough drilling bottom hole is Φ5mm, semi-finishing milling bottom hole to Φ5.9mm, semi-finishing boring bottom hole to Φ5.96mm, finishing reaming group to final size

[0034] 3) The setting of CNC machining cutting parameters. Combined with the cutting performance of 15-5PH stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com