Mold table facilitating height adjusting and used for mold production

A technology for adjusting height and mold table, applied in the direction of manufacturing tools, grinding machine parts, and fixing grinding wheel devices, etc., can solve the problems of reducing efficiency, troublesome and cumbersome mold replacement, increasing manpower input, etc., to reduce pressure. , convenient clamping, reducing the effect of rigid contact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

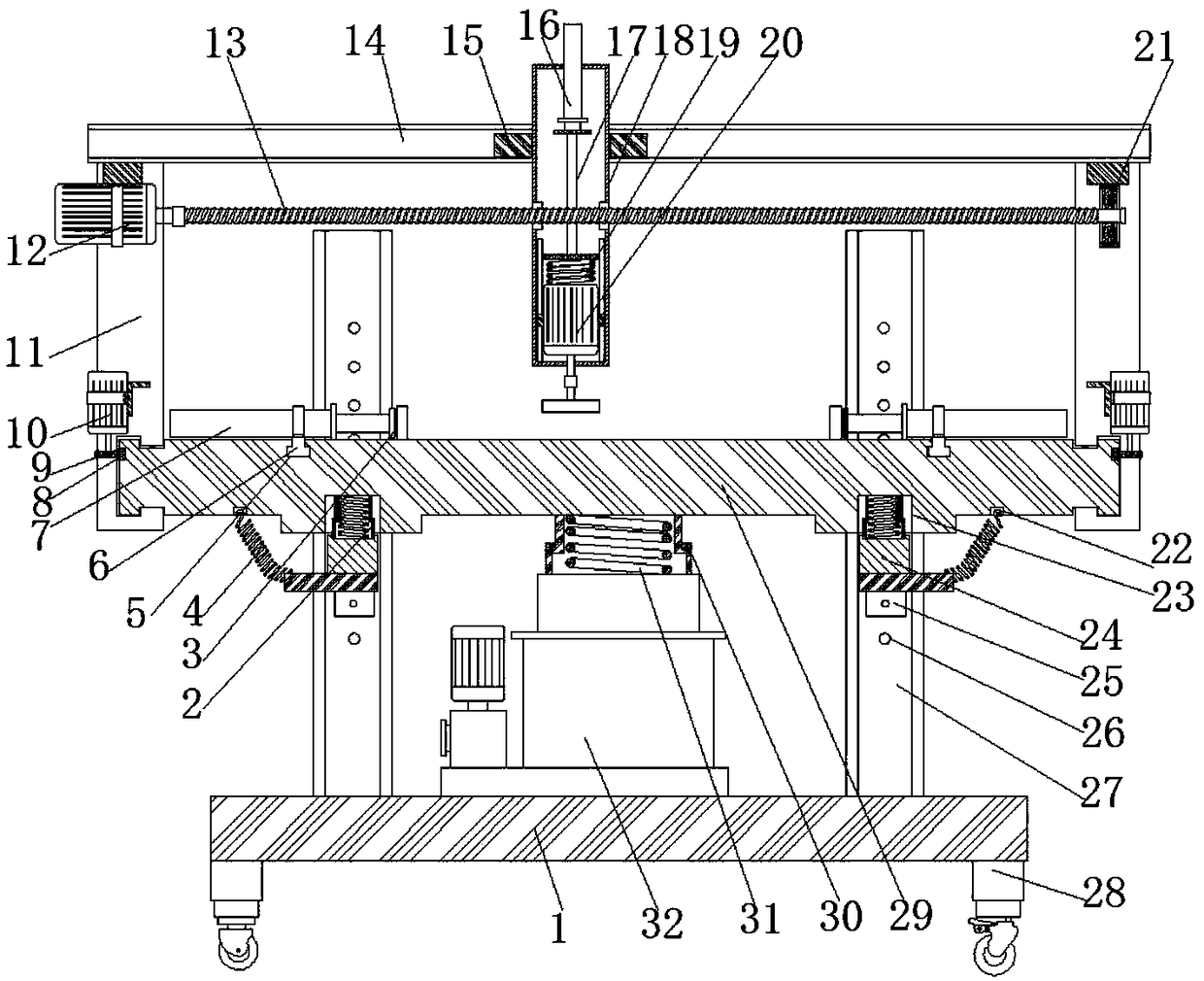

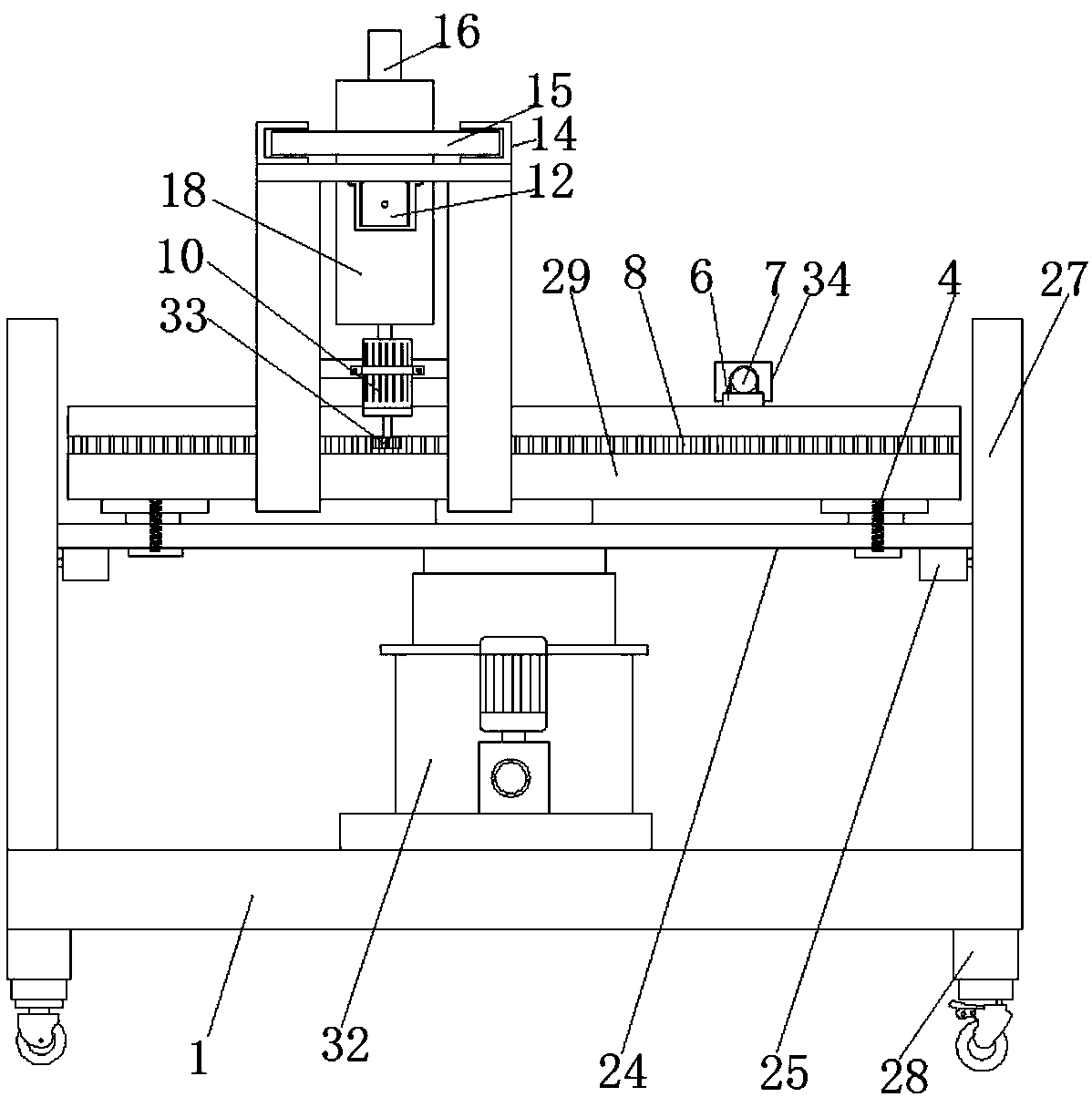

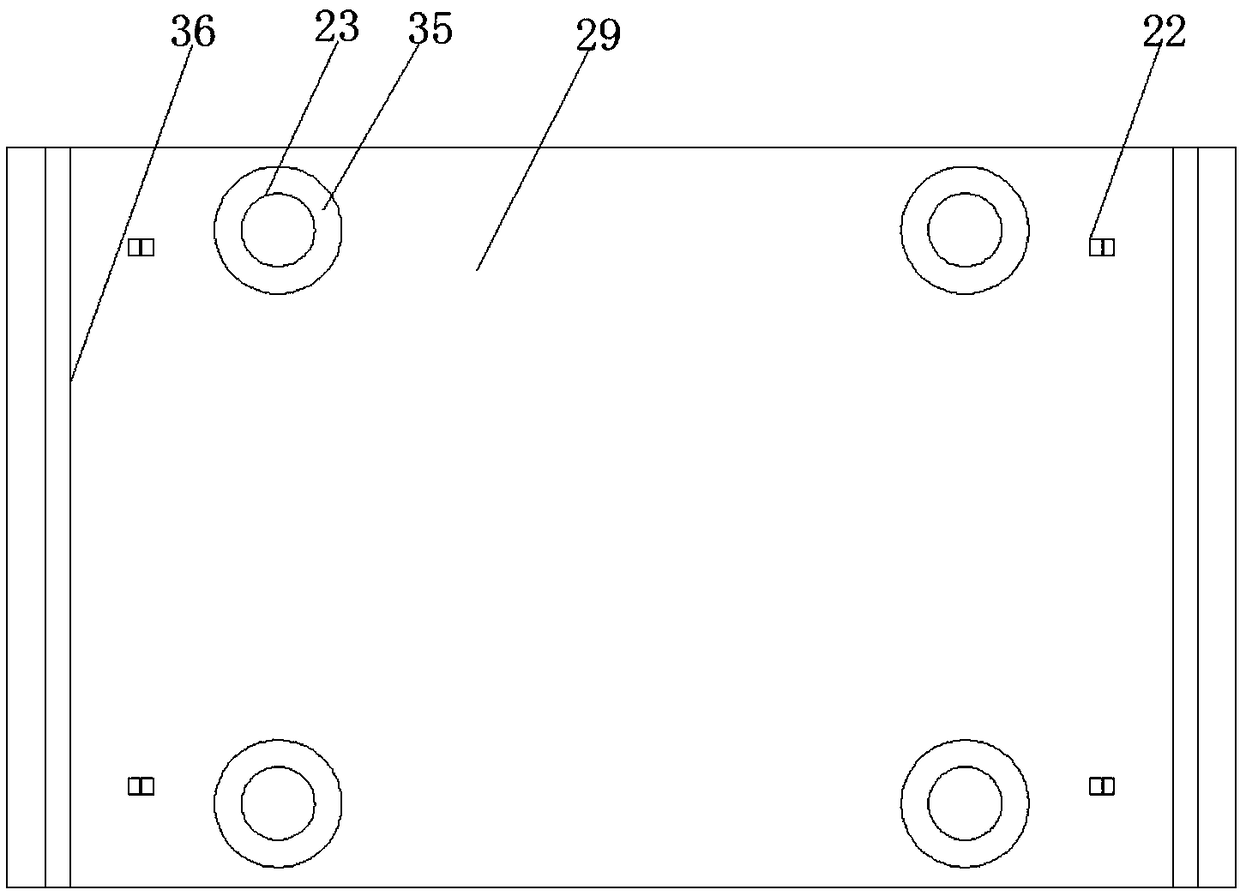

[0027] refer to Figure 1-5 , a mold table that is convenient for height adjustment for mold production, including a base 1, four channel steel columns 27 are welded on the upper surface of the base 1 near both sides, and the openings of the four channel steel columns 27 are opposite to each other, and the channel steel columns 27 There are limit holes 26 equidistantly distributed at the bottom of the bottom, and the same square rod 24 is slidably connected between the two channel steel columns 27 opposite to the opening, and the lower surface of the square rod 24 is fixed by screws near the edges of both ends. The electric control positioning pin 25, and the shaft d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com