Shot blasting device for shot blasting machine

A technology of shot blasting device and shot blasting machine, which is applied in the field of wire material processing, can solve problems such as waste of resources, uneven cleaning, and inability to adjust the shot blasting angle, so as to achieve the effect of ensuring the quality of shot blasting and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

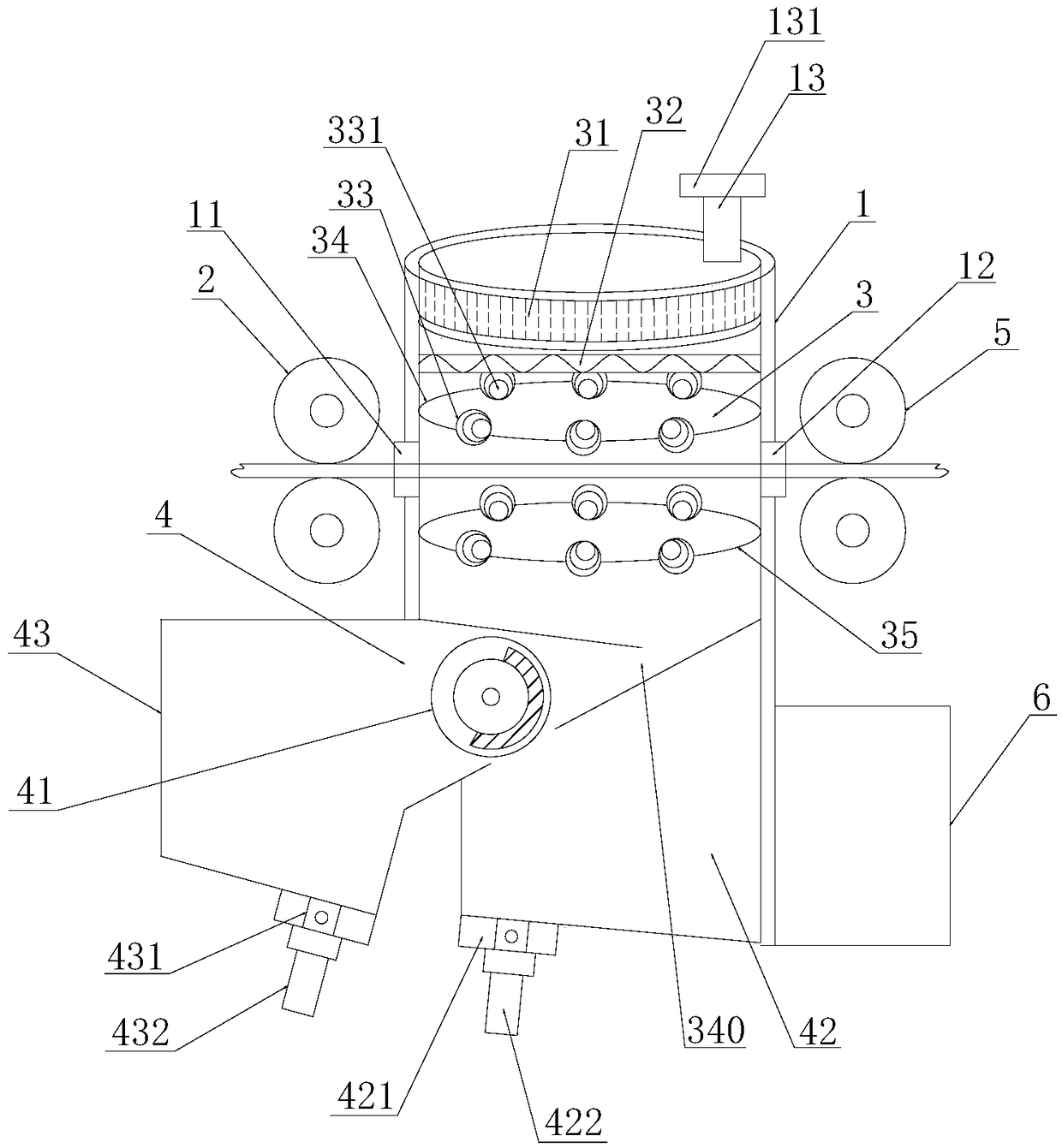

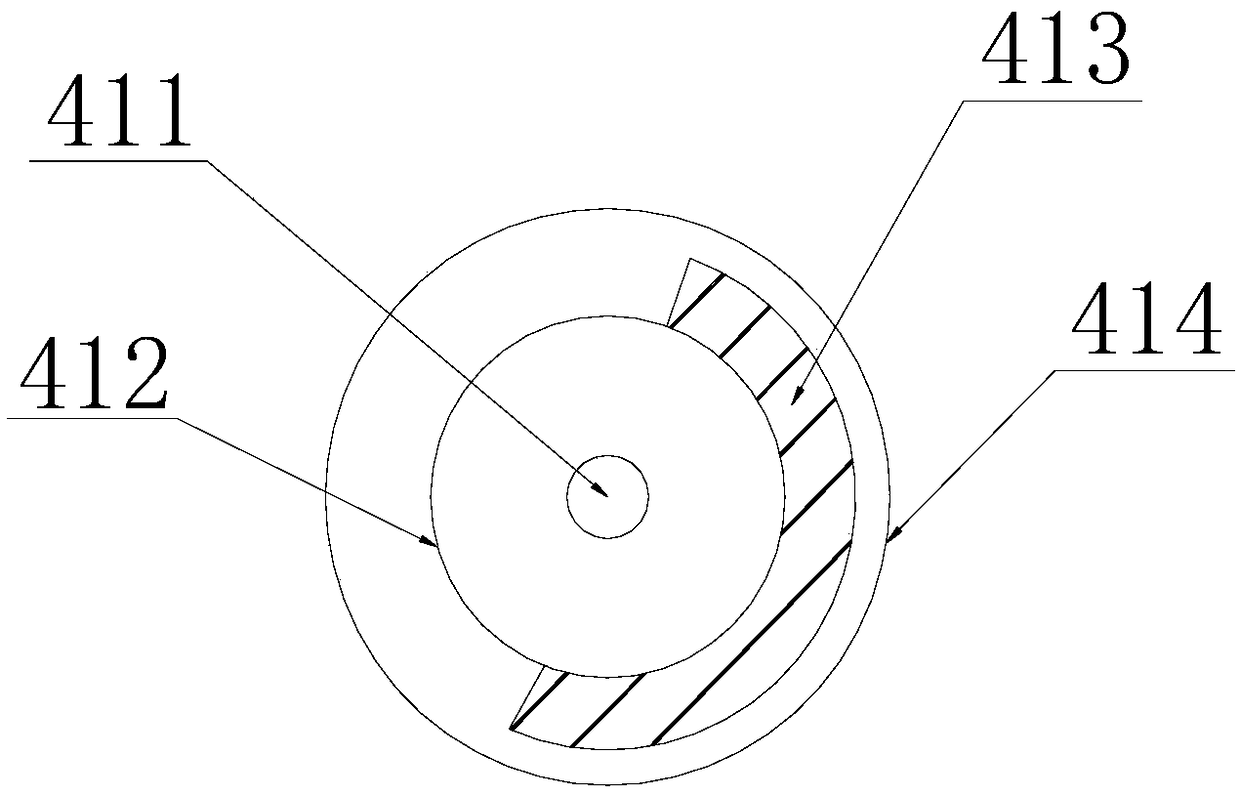

[0018] refer to figure 1 and figure 2 , the shot blasting device of a kind of shot blasting machine of the present invention, comprises shot blasting bin 1, feeding pair of rollers 2, shot blasting mechanism 3, pill slag separation mechanism 4, discharging pair of rollers 5 and control mechanism 6, described shot blasting The left and right sides of the bin 1 are respectively provided with a pair of feeding rollers 2 and a pair of discharging rollers 5. The shot blasting bin 1 includes a shot blasting mechanism 3 and a shot slag separation mechanism 4. The shot blasting mechanism 3 includes a The shot chamber 31 of the material, the high-pressure dust suction fan 32 and several blasting devices 33, the blasting device 33 is provided with a projecting port 331 that can adjust the projecting angle, and the blasting device 33 is connected with the shot chamber 31 A shot blasting mechanism 3 is provided with a shot blasting mechanism 4 below, a shot blasting channel 340 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com