Brake resistor for implementing auxiliary heater

A technology of braking resistors and machines, applied in the direction of machines/engines, engine starting, heating/cooling equipment, etc., can solve quite expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

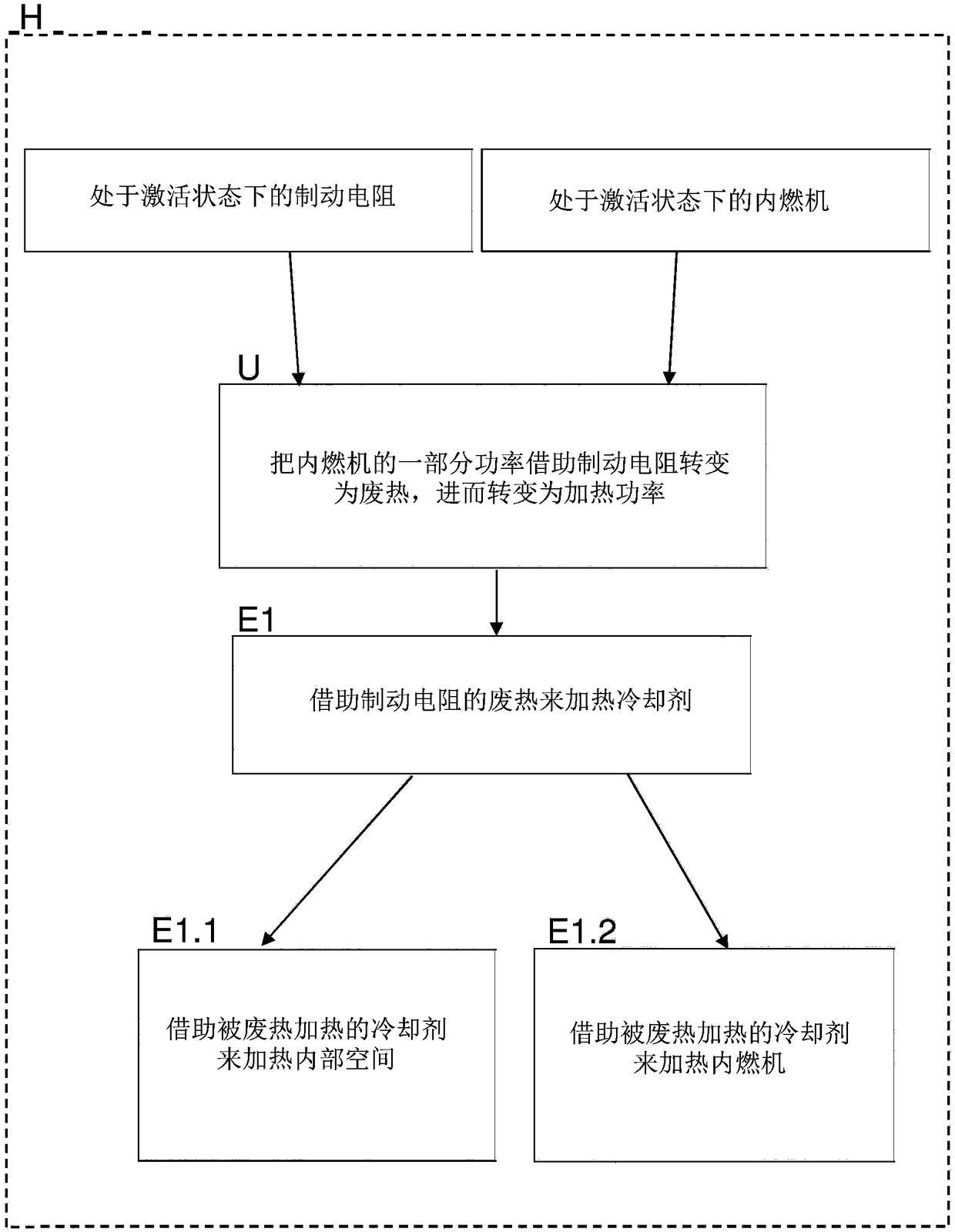

[0025] The dotted line very schematically represents an electric hybrid vehicle H, wherein the hybrid vehicle H has an internal combustion engine for burning fuel, an electric drive machine, and a coolant circuit which conducts coolant and surrounds the internal combustion engine. As usual, the internal combustion engine and the electric drive machine are used to drive the hybrid vehicle H, wherein the coolant circuit is firstly used as usual to cool the internal combustion engine. The internal combustion engine is preferably a diesel engine, whereby the fuel is preferably diesel.

[0026] A braking resistor is installed in the coolant circuit. The braking resistor generates waste heat in step E1 in order to heat the coolant.

[0027] The waste heat of the braking resistor is used in step E1.1 to heat the interior of the hybrid vehicle H via the coolant. In addition, the waste heat of the braking resistor can be used to heat the internal combustion engine via the coolant in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com