Electric brake system, railway wagon and brake method thereof

A railway freight car, electric braking technology, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve problems such as poor braking performance, reduce impact, solve poor braking performance, and reduce interaction force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

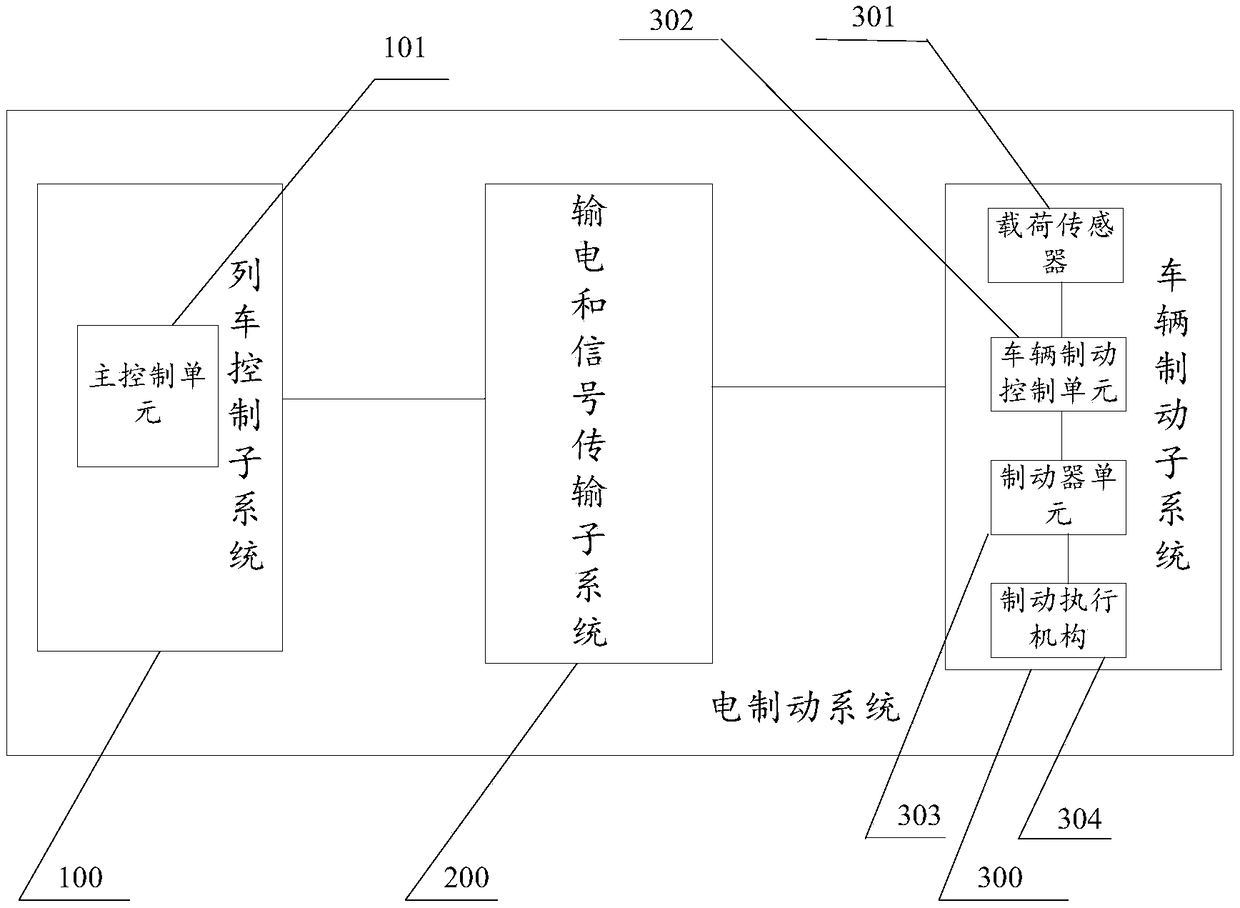

[0048] This embodiment provides an electric braking system, which is applied to railway wagons, and railway wagons include vehicles, such as figure 1 As shown, the system includes: a train control subsystem 100, a power transmission and signal transmission subsystem 200, and a vehicle braking subsystem 300, wherein the power transmission and signal transmission subsystem 200 is used to transmit electric energy and transmit control signals;

[0049] The train control subsystem 100 includes:

[0050] The main control unit 101 is configured to generate a braking control command, and send the braking control command to the vehicle braking control unit through the power transmission and signal transmission subsystem 200;

[0051] Vehicle braking subsystem 300 includes:

[0052] The load sensor 301 is used to detect the load of the vehicle and feed back the load of the vehicle to the vehicle brake control unit;

[0053] a vehicle braking control unit 302, configured to generate a ...

Embodiment 2

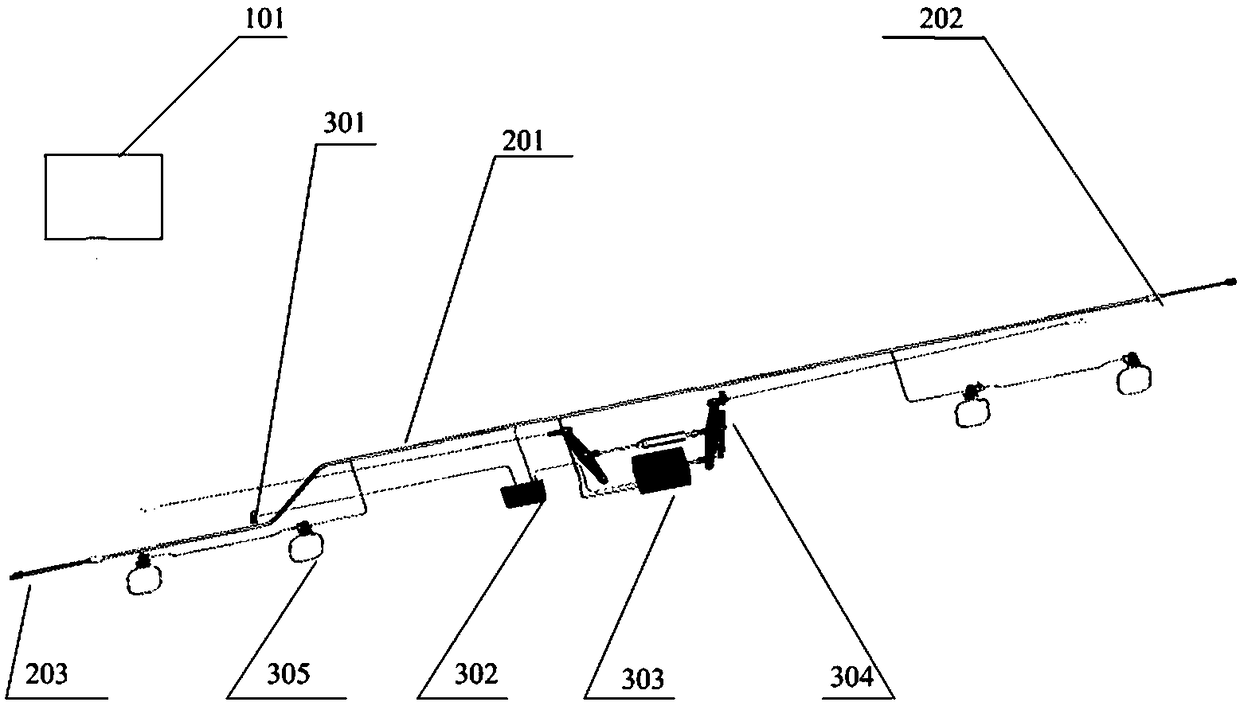

[0085] Based on the same inventive concept as in Embodiment 1, Embodiment 2 of the present invention provides a railway freight car, including a car body, a bogie, and a coupler buffer device. The railway freight car also includes the electric braking system described in Embodiment 1. The driving system is arranged on the vehicle body.

[0086] Specifically, the car body is the main body of a railway freight car, which is a container for cargo, and the bogie is the running part of a railway freight car, mainly used to support the car body, turn and brake, so as to ensure that the vehicle can run smoothly on the track . The coupler buffer device is the connection device between the vehicles, which can make the vehicles connected to each other to form a train, and can ease the longitudinal impulse between the vehicles. As an option, the railway may also include vehicle internal equipment, such as equipment for fixing cargo, equipment for loading and unloading cargo, and refrige...

Embodiment 3

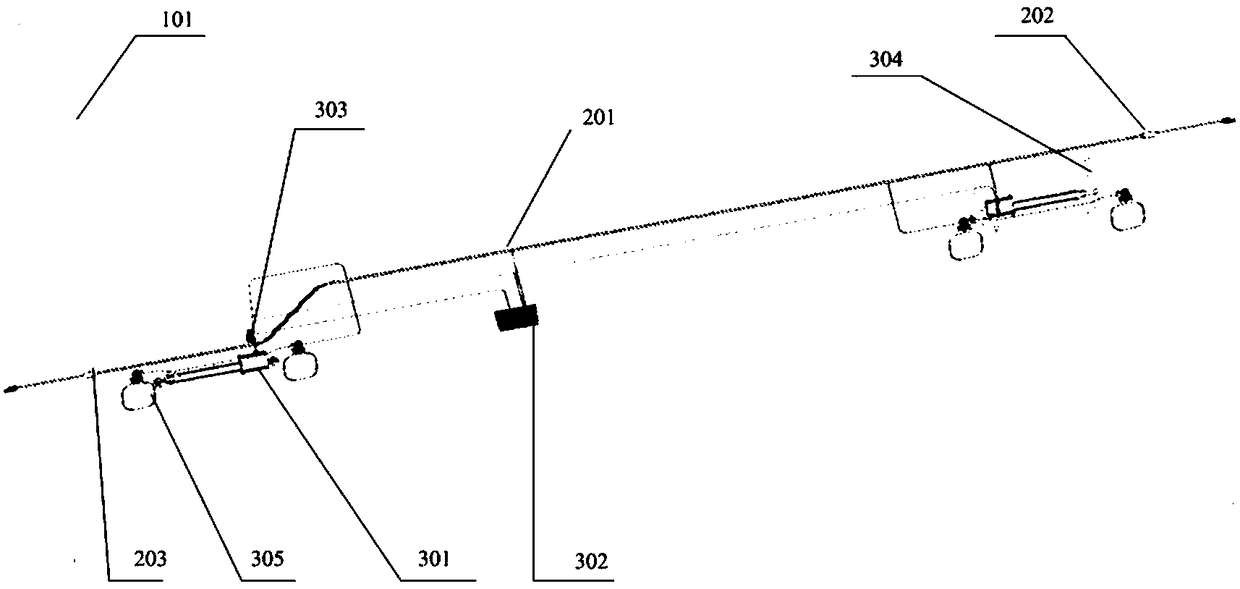

[0089] Based on the same inventive concept as in Embodiment 1, Embodiment 3 of the present invention provides a railway freight car, including a car body, a bogie, and a coupler buffer device. The railway freight car also includes the electric braking system described in Embodiment 1. The moving system is set on the bogie.

[0090] In this embodiment, the electric braking system is set on the bogie, see for details image 3 , the electric braking system includes a train control subsystem (101), a power transmission and signal transmission subsystem (a whole composed of 201, 202 and 203) and a vehicle braking subsystem (a whole composed of 301, 302, 303, 304 and 305) , wherein the specific structure and composition of the electric braking system have been described in detail in the first implementation, so it will not be repeated here, and all the electric braking systems and their denaturation in the first implementation belong to the protection scope of this embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap