Preset laser cladding shielding gas filling device

A laser cladding and shielding gas technology, which is applied in the field of preset laser cladding shielding gas filling devices, can solve the problems of powder splashing and powder waste, and achieve the effects of reducing waste, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

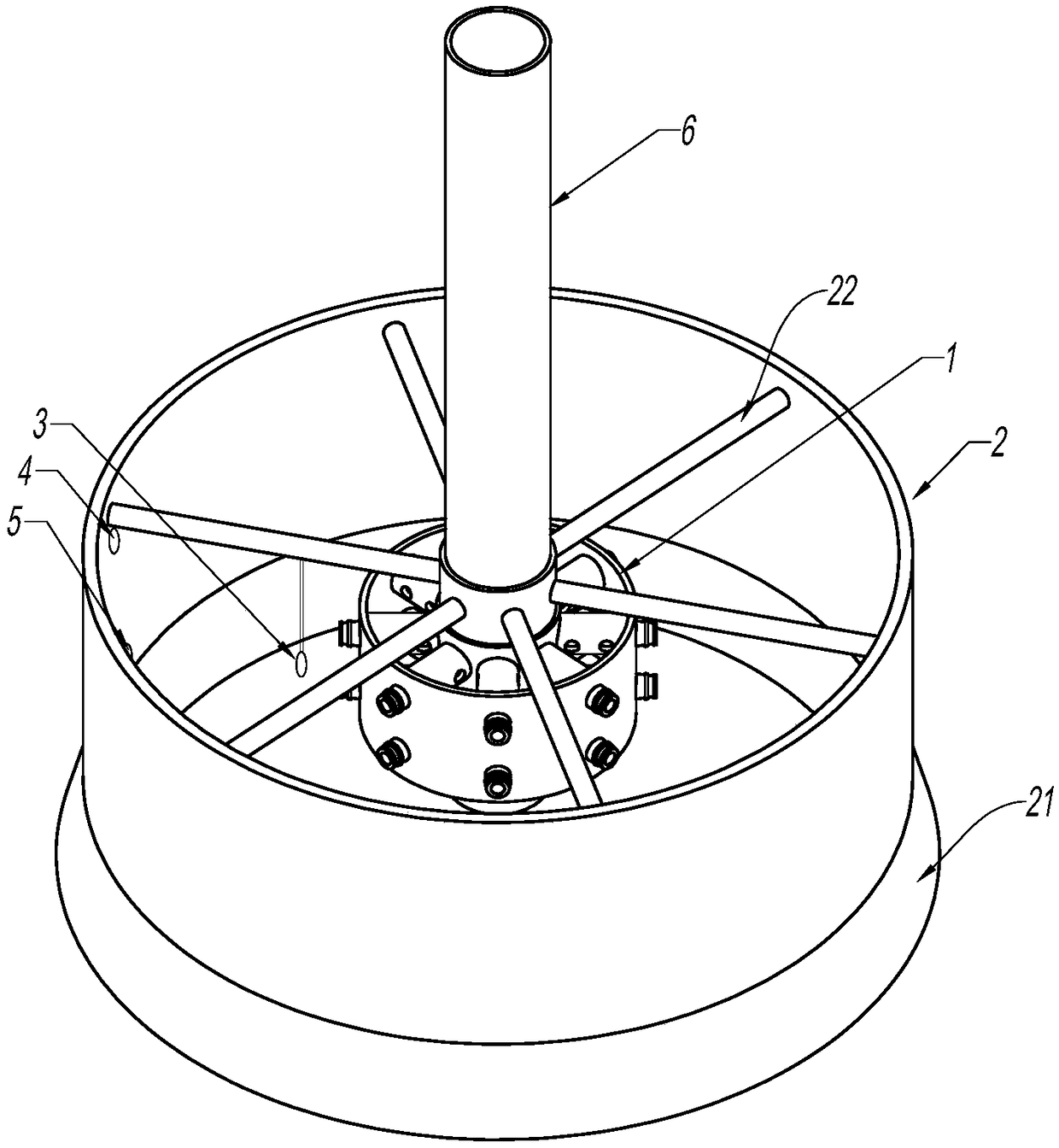

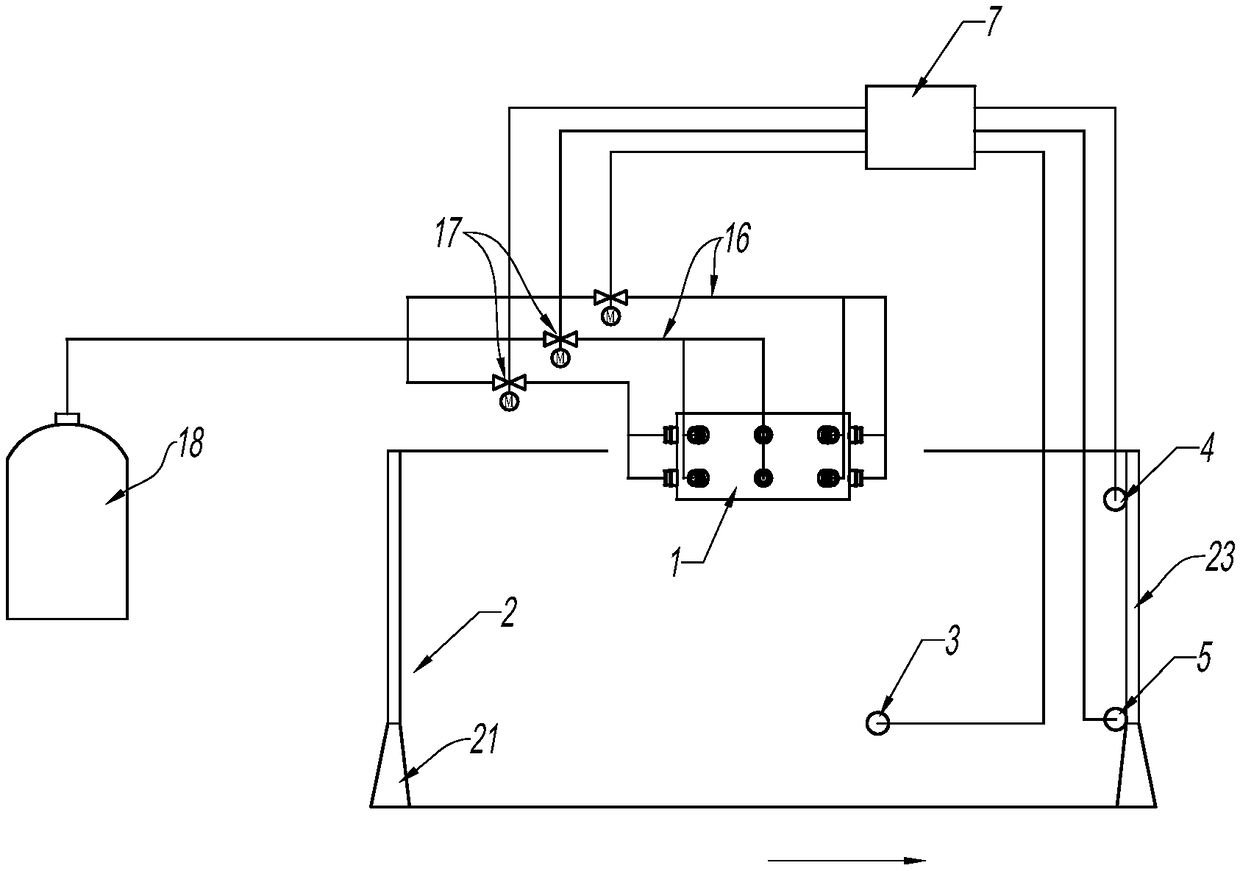

[0023] refer to figure 1 , figure 2 and image 3 , a preset laser cladding protective gas filling device, including a clamping nozzle 1, and a circular gas cover 2, the first sensor 3, the second sensor 4 and the third sensor 5.

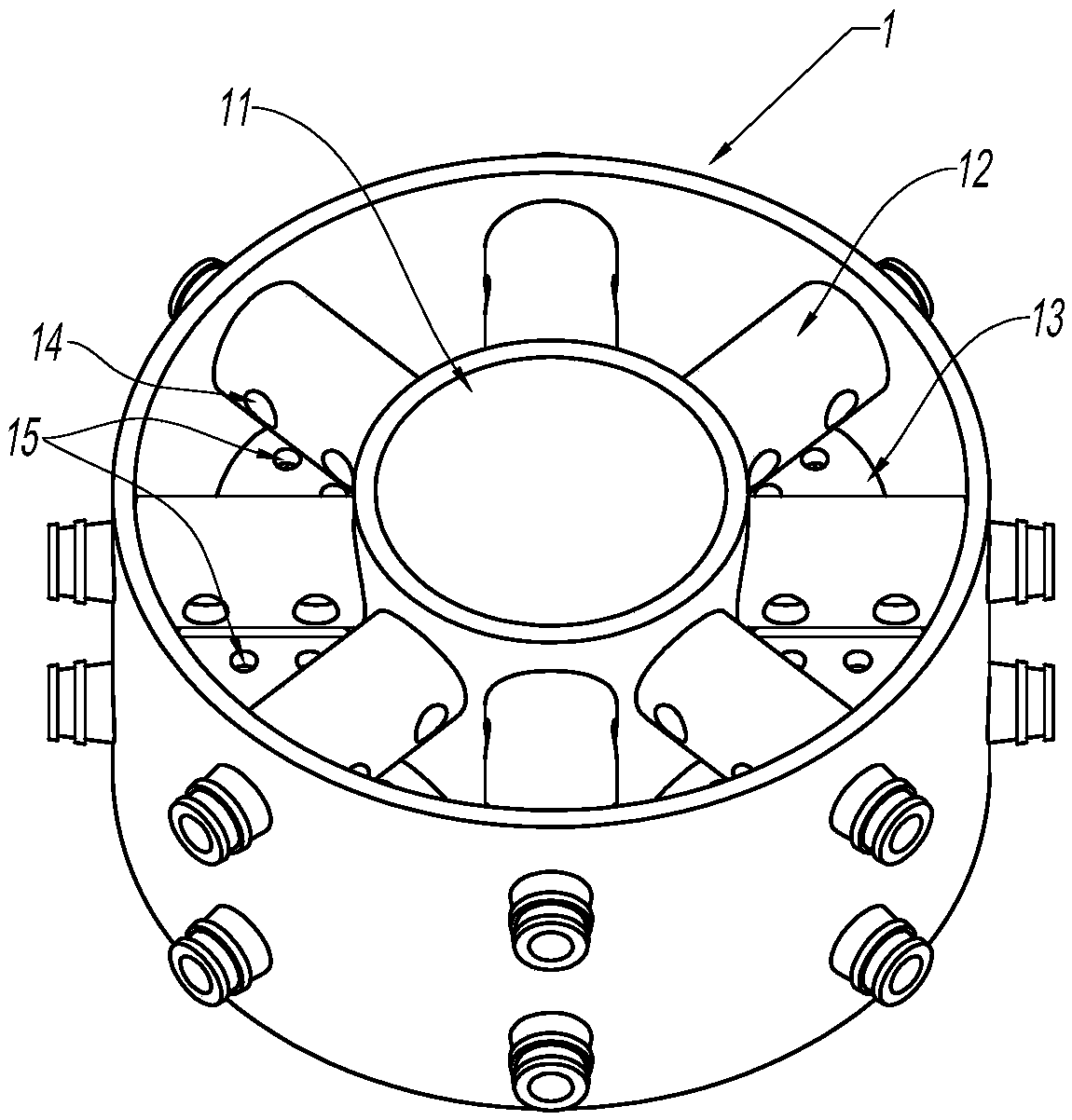

[0024] The clamping nozzle 1 has a central sleeve 11 and two radial air pipes, that is, the upper air pipe 12 and the lower air pipe 13. The upper air pipe 12 has horizontal air outlet holes 14 on both sides, and the upper air pipe 13 has an upward air outlet 15. . Further, four to ten upper-layer air pipes 12 and lower-layer air pipes 13 are arranged on the clamping nozzle 1, and the upper and lower-layer air pipes 12, 13 are projected to overlap, so that the upward air outlet 15 of the lower-layer air pipe can blow against the bottom of the upper-layer air pipe 12 to protect The gas diffuses left and right, mixes evenly with the airflow blown out from the horizontal air outlet hole 14 of the upper trachea, and sinks in a diffusive manner, exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com