Assembly-type ground leveling structure and installing method

An installation method and prefabricated technology, applied in the direction of floors, building structures, local raised floors, etc., can solve the problems of high material transportation costs, large flatness errors, slow construction speed, etc., and achieve convenient and fast construction. High degree and low workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

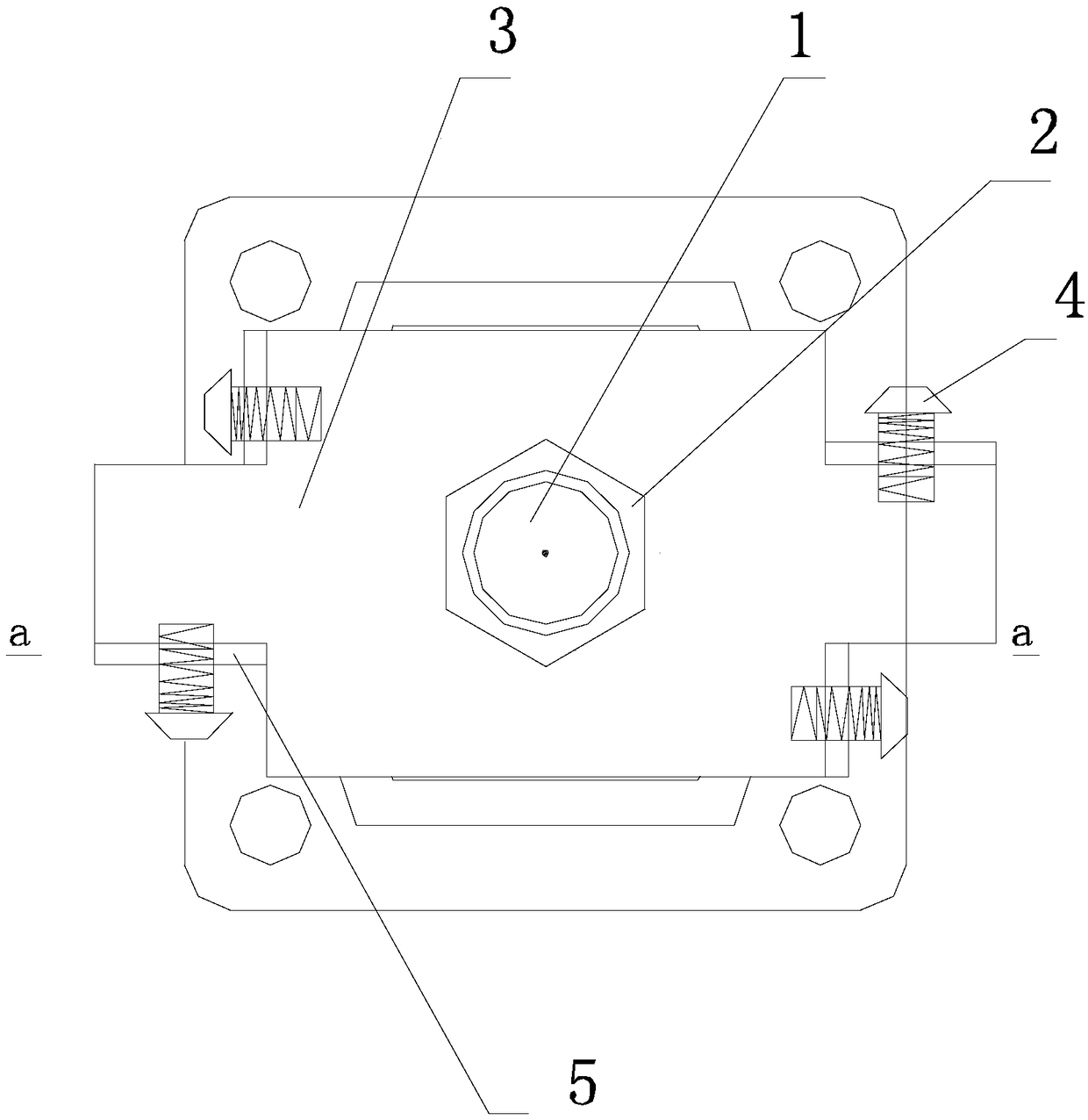

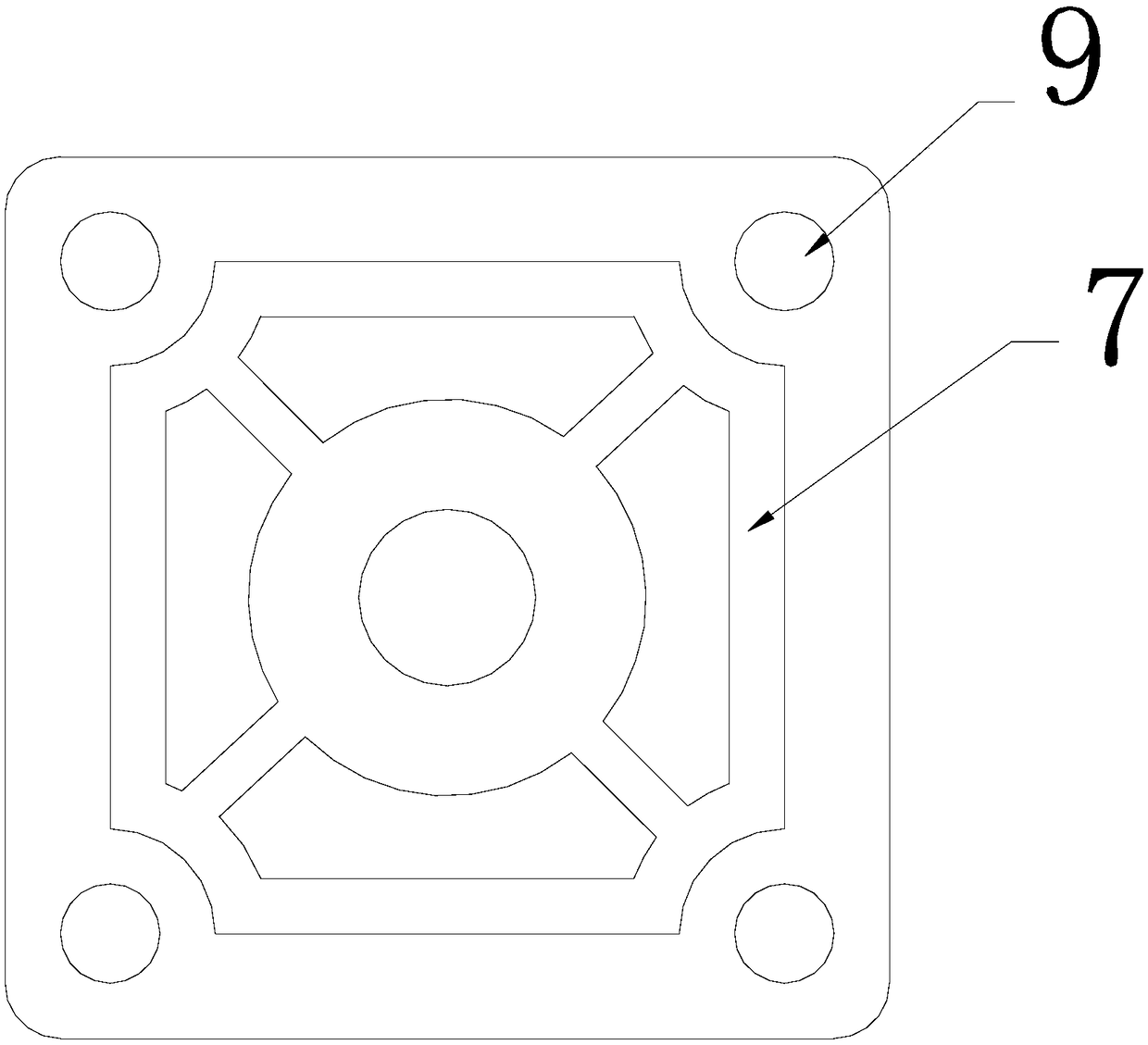

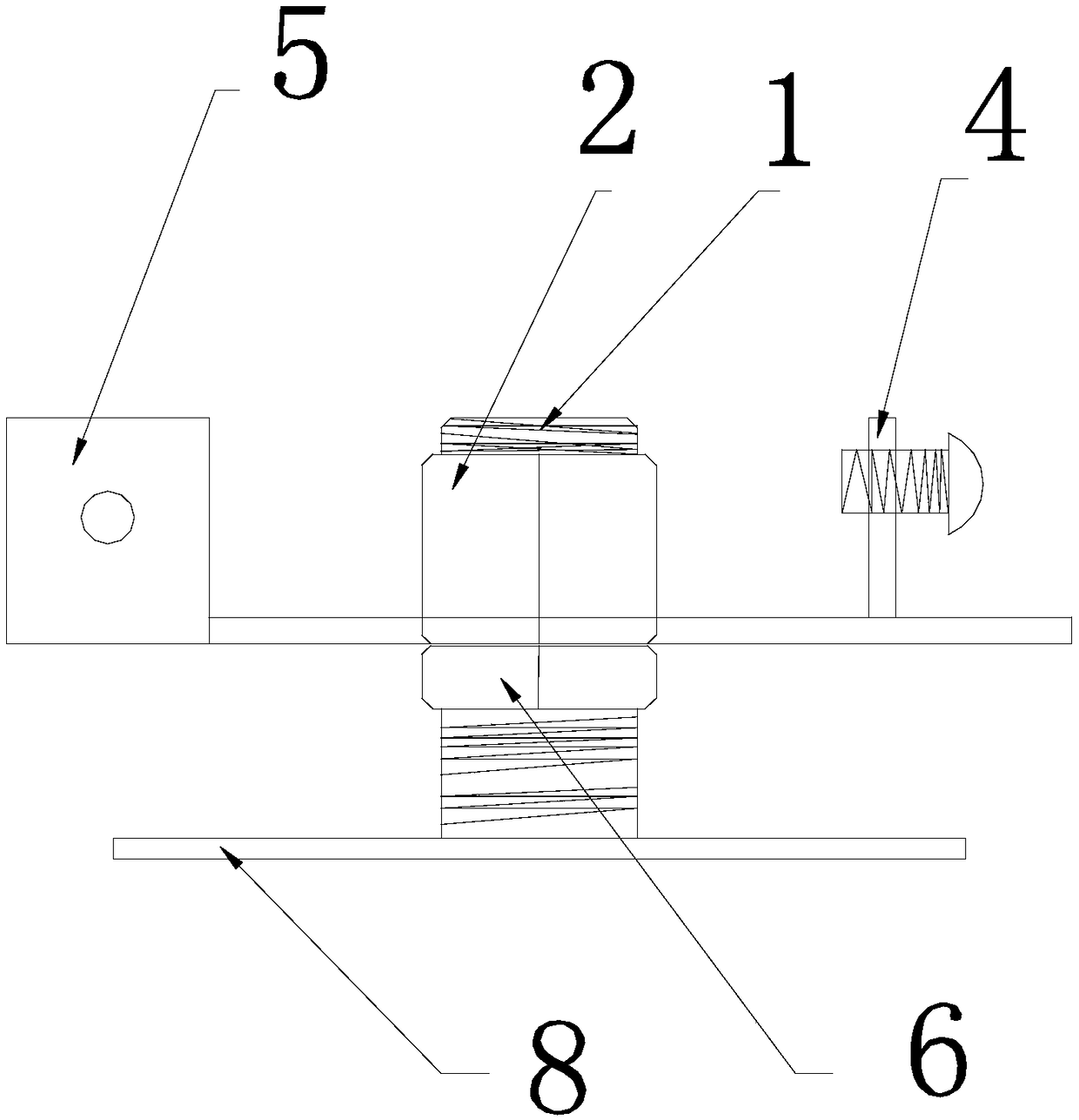

[0030] like figure 1 , figure 2 and image 3 As shown, the assembled ground leveling structure of the present application includes a base 8, a height adjustment screw 1, an assembly keel positioning fixing nut 2, a positioning screw and an assembly support plate 3, and the base 8 is connected with the height adjustment screw 1, The assembly keel positioning fixing nut 2 is arranged on the height adjustment screw 1, the assembly supporting plate 3 is connected with the assembly keel positioning fixing nut 2, and the assembly supporting plate 3 is provided with a square tube keel positioning On the vertical plate 5 , the square tube keel positioning vertical plate 5 is provided with a fixed square tube keel screw 4 . The base 8 can be connected and fixed with the ground through expansion bolts. When the prefabricated ground leveling structure of the present applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com