Device and method for measuring critical rebound speed of hot fly ash particle

A rebound velocity, measuring device technology, applied in measuring device, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of limited impact velocity adjustable range, inability to directly measure the critical rebound velocity of particles, etc., to avoid effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

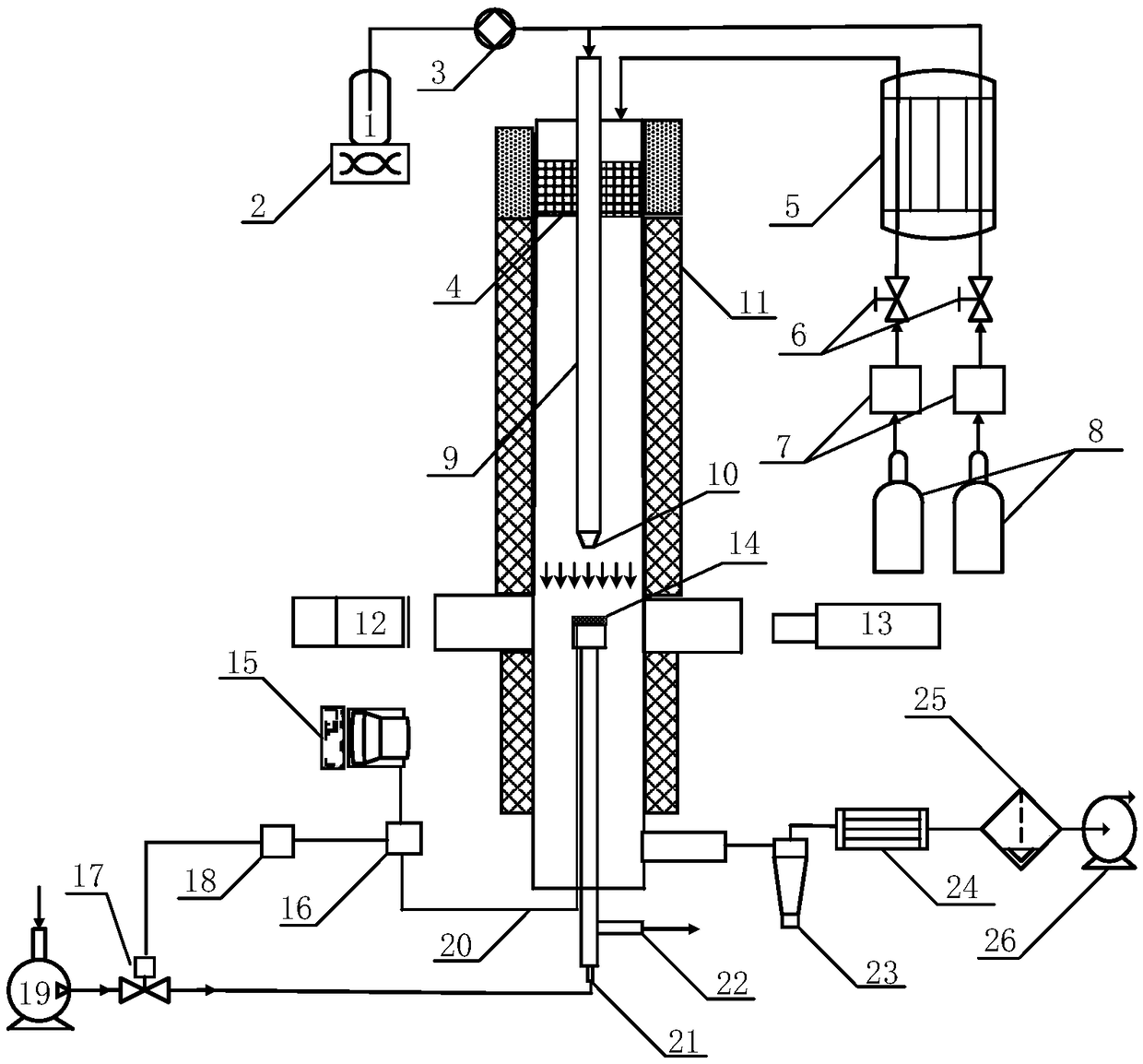

[0038] Such as figure 1 As shown, a thermal collision test device for fly ash particles in this embodiment is mainly used to more realistically simulate the characteristics of the collision between fly ash particles and the surface of the heat exchanger under the high temperature condition of the boiler. The collision process of the parts that are prone to ash and slagging on the surface of the inner heat exchanger, through the experiment of fly ash particles hitting the surface of the heat exchanger under different airflow velocities, judge the critical rebound velocity when the fly ash particles of different particle sizes hit the platform , so as to provide experimental data for the modeling of the critical rebound velocity.

[0039] In addition to the heating furnace 11, infrared thermal imaging camera 12, high-speed camera 13, and support platform 14 included in traditional similar experimental devices, the device also includes fly ash supply components, gas source compon...

Embodiment 2

[0050] This example provides the method of using the fly ash particle thermal state collision test device in Example 1, which can simulate the impact of fly ash particles under conditions such as different particle sizes, different furnace temperatures, different incident velocities, and different heat exchanger surface materials. Collision experiments, more comprehensive, reliable and accurate research on the thermal collision characteristics of fly ash particles.

[0051] The method for using the critical rebound velocity measuring device of hot fly ash particles is as follows:

[0052] First, take milligram-level fly ash and put it into the fly ash container 1, add water to dilute it, and stir it with a magnetic stirrer 2; The nitrogen gas heated by the preheating furnace 5 enters the furnace 9, and the water vapor evaporates rapidly in the furnace 9, while the fly ash particles are ejected from the lower end of the furnace 9 and shoot to the surface of the supporting platf...

Embodiment 3

[0057]This embodiment provides a method for measuring the critical rebound velocity of hot fly ash particles, using the experimental device in Example 1 to measure the critical rebound velocity when the fly ash particles hit the support platform 14 . The critical velocity is an important parameter in the impact process. When the incident velocity of the particles is lower than the critical velocity, the particles will deposit, resulting in dust accumulation on the heat exchange surface; when the incident velocity of the particles is higher than the critical velocity, the particles will rebound. The specific operation steps are:

[0058] First, adopt the method of Embodiment 2 to carry out the operation of fly ash particles hitting the support platform 14, and calculate the normal incident velocity and normal rebound velocity of the fly ash particles by taking photos before and after the fly ash particles hit the support platform 14 by the high-speed camera 13. The method of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com