Test pin module and test contact formed by test pin modules

A test pin and contact piece technology, applied in the direction of measuring leads/probes, etc., can solve problems such as contact failure between test pins and product pins, and achieve the effect of increasing the effective contact area, reducing contact failure, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

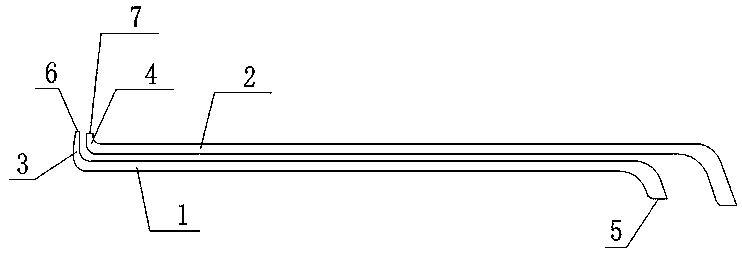

[0022] Such as figure 1 As shown, a test needle assembly includes at least two test needle groups arranged side by side, the test needle group includes a first test needle body 1 and a second test needle body 2, and the second test needle body 2 is arranged on Above the first test pin body 1. The first test needle body 1 is provided with a first test needle 3 , and the second test needle body 2 is provided with a second test needle 4 on the right side of the first test needle 3 . At the same time, the first test needle 3 is provided with a first test needle contact surface 6 for contacting with product pins, and similarly, the second test needle 4 is provided with a second test needle contact surface 7 . The test pin assembly of the present invention is used for contacting and testing product pins, and the test pin assembly includes at least two sets of test pins, and each test pin set includes two surfaces that are in contact with product pins, then When the new type is use...

Embodiment 2

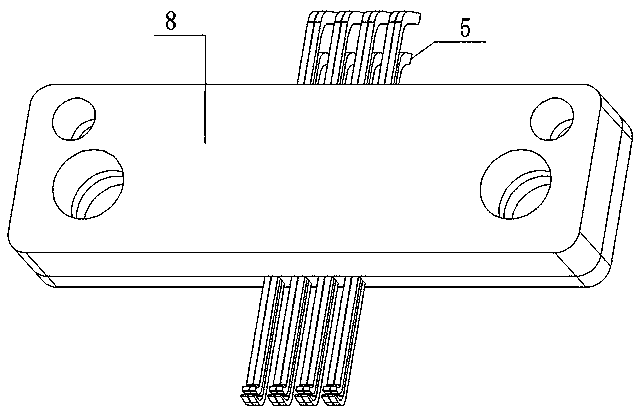

[0025] Such as figure 2 As shown, the test contact sheet of the present invention includes a test contact sheet substrate 8 on which at least one test pin assembly as described in Embodiment 1 is provided. The test pin assembly is fixed on the test contact sheet substrate 8, and an insulating medium is filled between the first test pin body 1 and the second test pin body 2, so as to ensure that the first test pin body 1 and the second test pin body 2 insulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com