Battery sampling system

A battery sampling and battery technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of poor conversion accuracy, incompetence for low-power applications, unbalanced battery cells, etc., and achieves high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

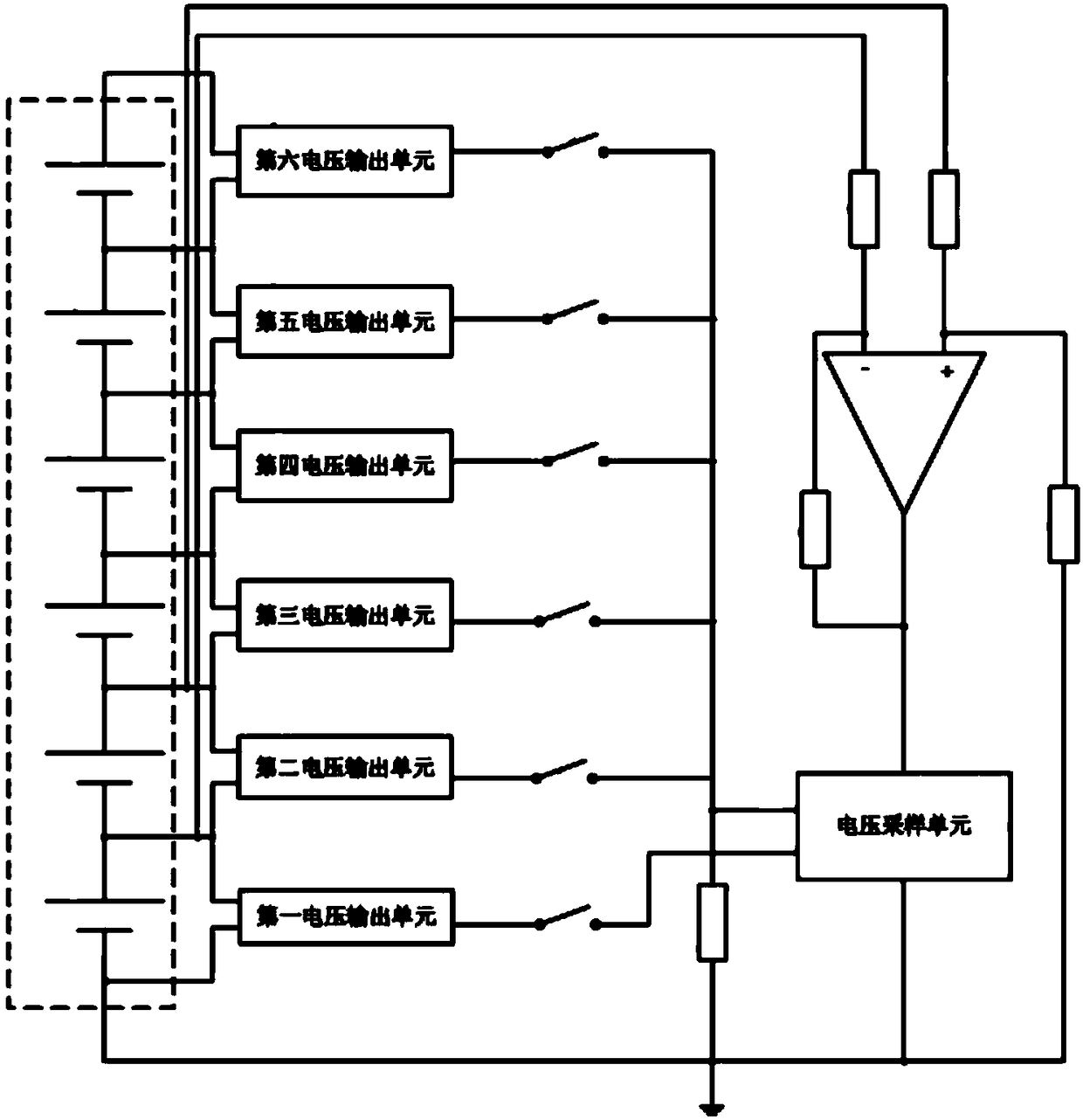

[0068] Such as Figure 4 As shown, the present embodiment provides a battery sampling system, and the sampling system 20 includes:

[0069] A battery pack 21, comprising the lowest battery, the second battery and the highest battery connected in series in sequence;

[0070] The lowest battery sampling circuit 22 is connected to the positive terminal, the negative terminal of the lowest battery and the positive terminal of the highest battery, and is used to draw a sampling current from the positive terminal of the highest battery, and transfer the lowest battery The battery voltage VB1 is converted to ground voltage for output;

[0071] The highest battery sampling circuit 23 is connected with the negative terminal of the lowest battery, the positive terminal of the second battery and the positive terminal of the highest battery, for sampling from the positive terminal of the highest battery current, and convert the voltage VB3 of the highest cell into a ground voltage for o...

Embodiment 2

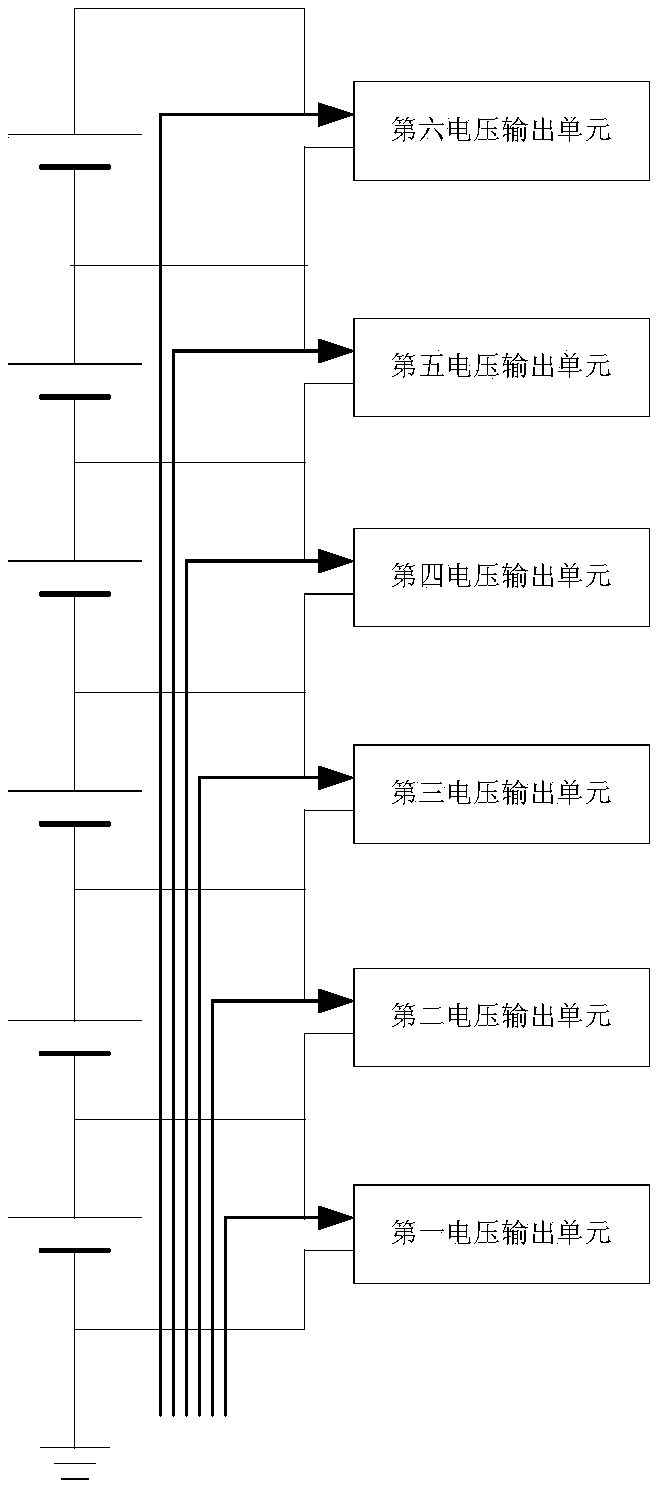

[0092] Such as Figure 5 As shown, the present embodiment provides a battery sampling system, and the sampling system 20 includes:

[0093] A battery pack 21, comprising the lowest battery, the second battery and the highest battery connected in series in sequence;

[0094] The lowest battery sampling circuit 22 is connected to the positive terminal, the negative terminal of the lowest battery and the positive terminal of the highest battery, and is used to draw a sampling current from the positive terminal of the highest battery, and transfer the lowest battery The battery voltage VB1 is converted to ground voltage for output;

[0095] The highest battery sampling circuit 23 is connected with the negative terminal of the lowest battery, the positive terminal of the second battery and the positive terminal of the highest battery, for sampling from the positive terminal of the highest battery current, and convert the voltage VB3 of the highest cell into a ground voltage for o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com