A method for manufacturing a composite wing box of a small and medium-sized unmanned aerial vehicle

A technology of composite materials and manufacturing methods, applied in computer-aided design, instrumentation, geometric CAD, etc., to achieve the effects of simplifying the molding process, reducing quality risks, and reliable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

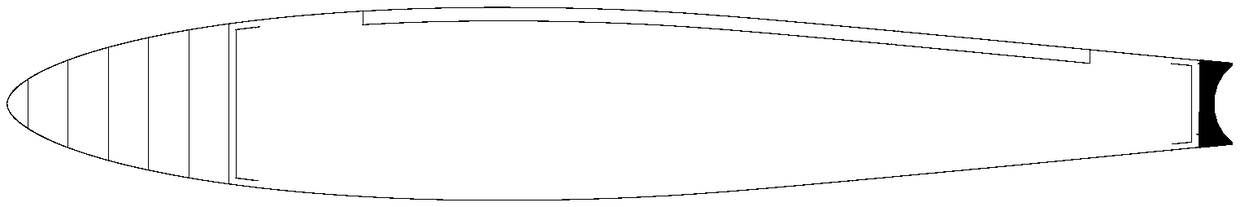

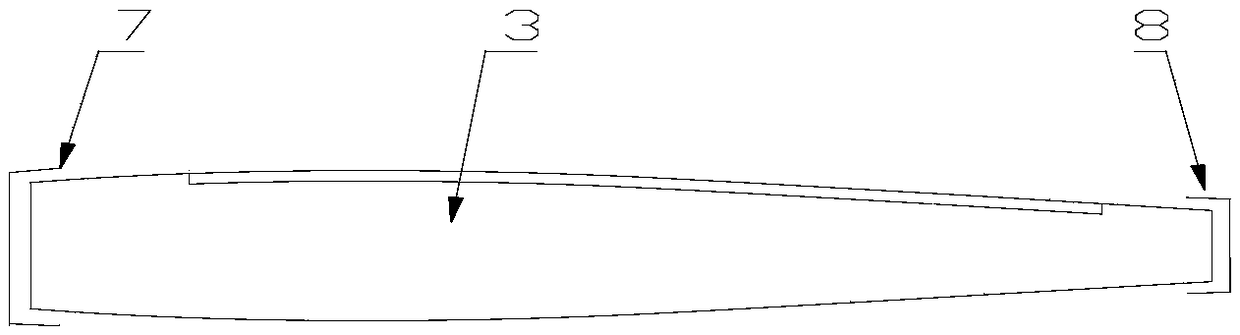

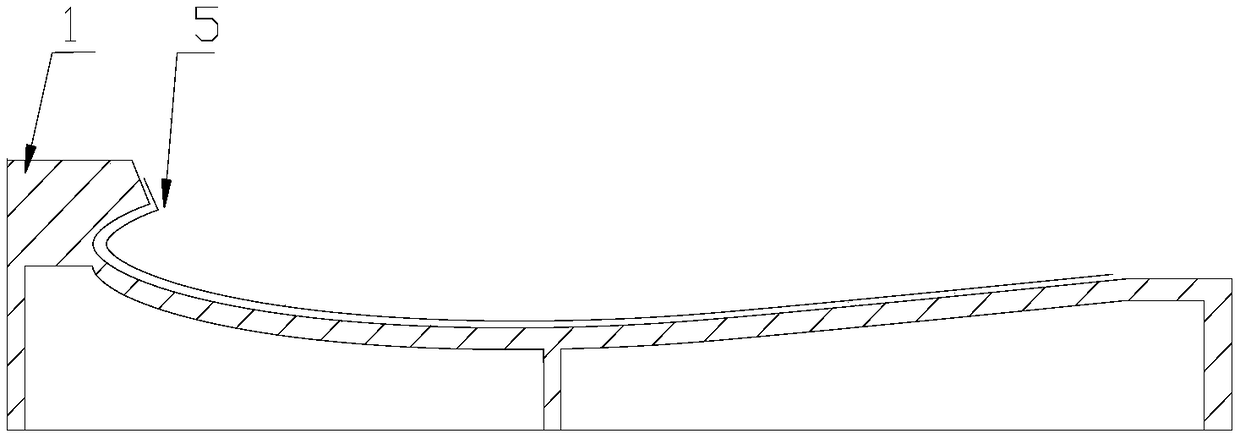

[0033] see figure 1 — Figure 7 , a method for manufacturing a wing box made of composite materials for small and medium-sized unmanned aerial vehicles, the process includes the following steps:

[0034] Step 1, tooling design: use 3D modeling to process the mold according to the digital model to obtain the overall forming mold. The block design is adopted in the design of tooling to ensure process molding and product demoulding; detachable positioning blocks are designed at both ends of the middle of the female mold 1 to facilitate the positioning and placement of the subsequent water-soluble mandrel 3 .

[0035] Step 2, manufacturing the water-soluble mandrel 3: using three-dimensional modeling, the mandrel is processed according to the digital model, and the water-soluble mandrel 3 is obtained, and then dried.

[0036] Step 3, preparation process: prepare leading edge foam parts 4 and prepreg for overall molding; unseal female mold 1, trailing edge forming module 2 and wa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap