Automatic filling algorithm of a tooth undercut mesh model on the basis of an included angle of normal vectors

A tooth model and automatic filling technology, which is applied in the field of tooth mesh model mesh model construction, can solve the problems of few automatic filling methods, complex control point selection rules, and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0100] Embodiments of the present invention and concrete process are as follows:

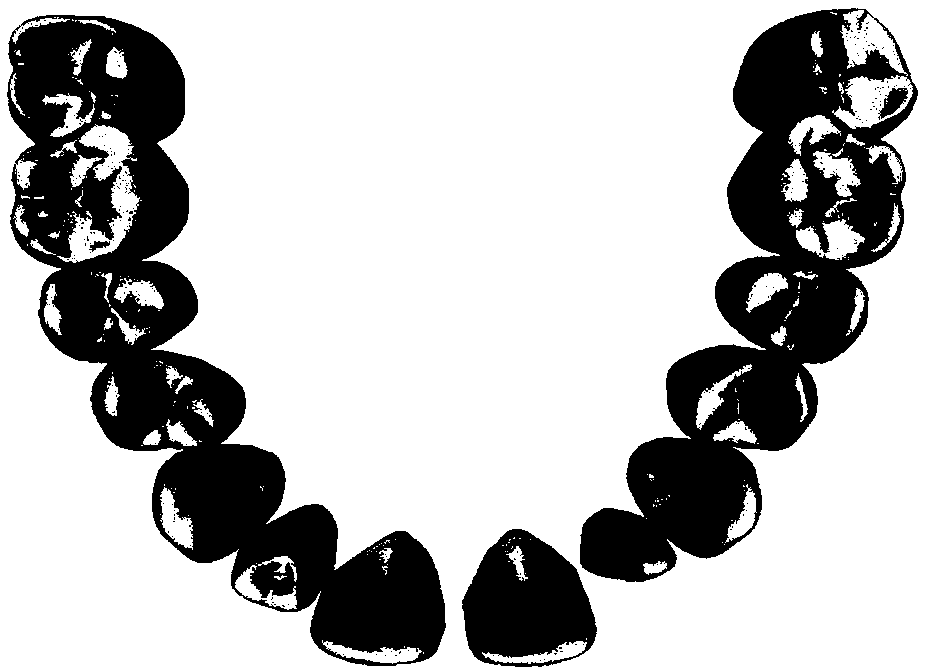

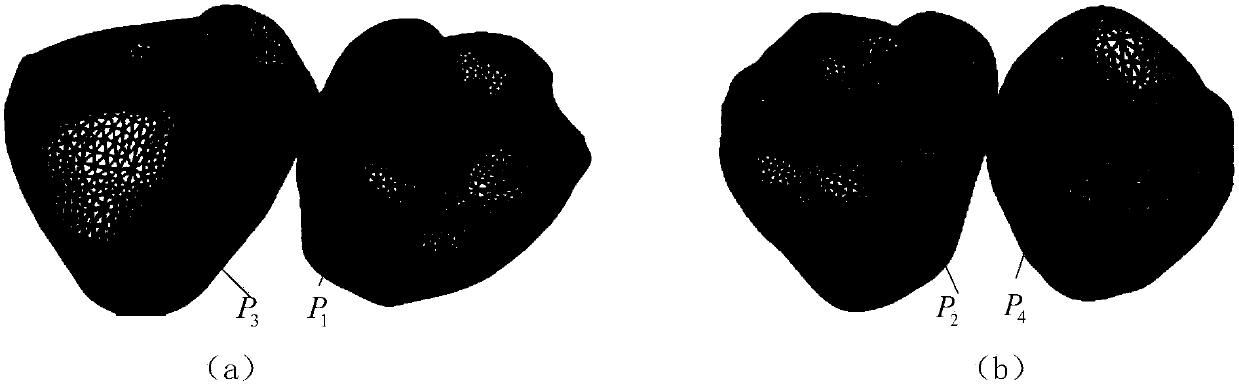

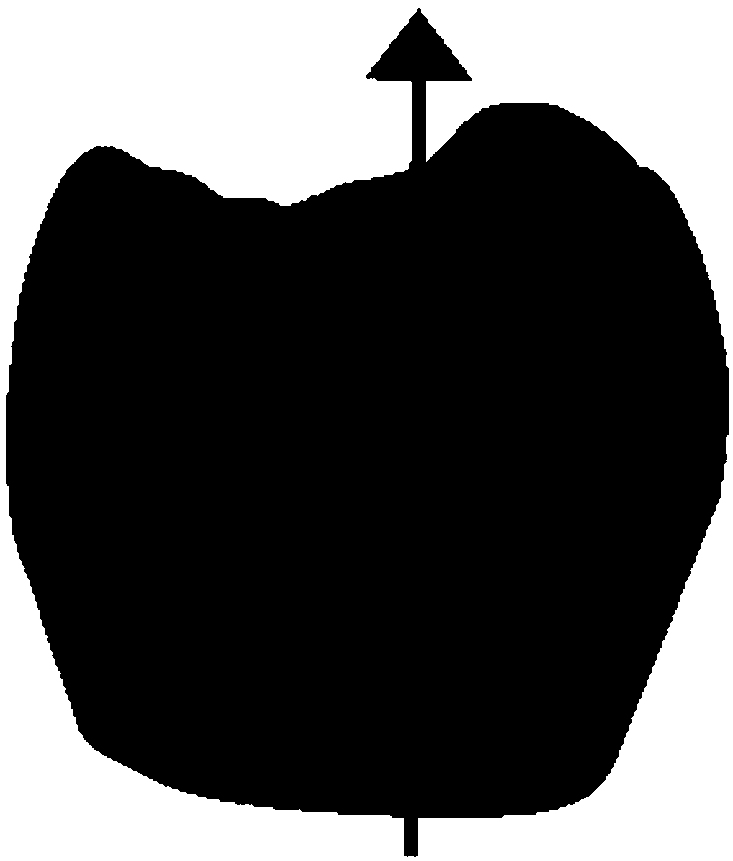

[0101] 1) Complete the naming of each tooth. The tooth name consists of 2 letters and 1 number. The first letter is U or L, which means upper teeth or lower teeth respectively, and the second letter is L or R, which means On the left or right side of the tooth, the third digit indicates which tooth is on one side of the tooth, input the model of the tooth and the local coordinate system, for this embodiment, such as figure 1 As shown, tooth UL1 represents the first tooth on the left side of the upper jaw. Identify undercuts for each interdental undercut region, such as figure 2 It is the front and back of the undercut area between the teeth UR7 and UR6 of the example, where the four points P 1 ~P 4 Indicates virtual gingival boundary points.

[0102] 2) According to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com