Low temperature polysilicon thin film transistor and manufacturing method thereof and display device

A low-temperature polysilicon and thin-film transistor technology, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as increasing production costs, and achieve the effects of overcoming production costs, simplifying production processes, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

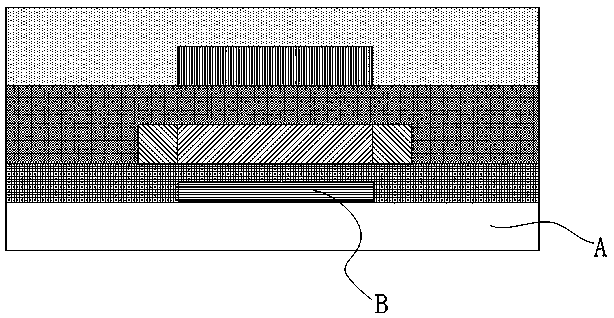

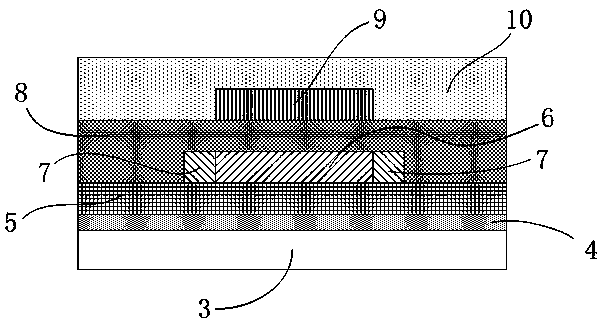

[0047] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

[0048] like figure 2 Shown is a method for manufacturing a low-temperature polysilicon thin film transistor provided by an embodiment of the present invention, and the method includes the following steps:

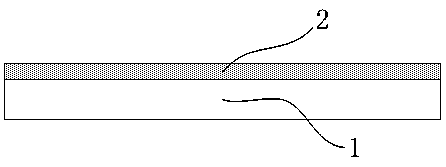

[0049] S100 providing a first substrate 1 and a second substrate 2;

[0050] In this embodiment, the first substrate 1 and the second substrate 2 are two substrates with the same thickness, length and width, both of which are made of glass, and the composition of the glass can be changed according to the actual situation, for example, The material of the glass is Na 2 SiO 3 , CaSiO 3 , SiO 2 ; Another example, the material of the glass is Na 2 O CaO 6SiO 2 For another example, polymethyl methacrylate can also be doped in the glass to obtain organic glass with strong chemical properties, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com