Special tool for quickly removing ice coatings of power transmission line

A technology for transmission lines and special tools, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of tower tilt and collapse, wire galloping fracture, flashover and other problems, achieve flexible and adjustable structure, improve the scope of application, improve The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

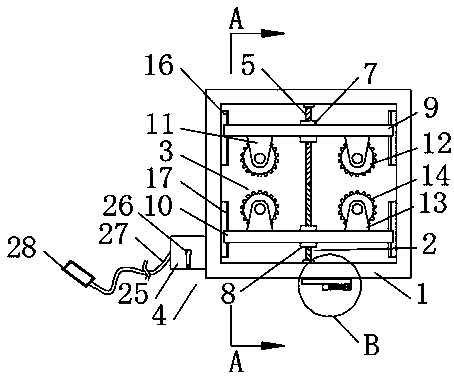

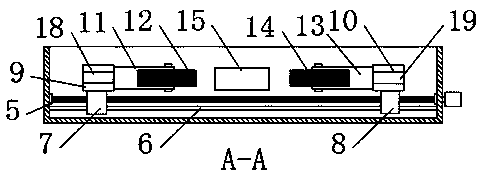

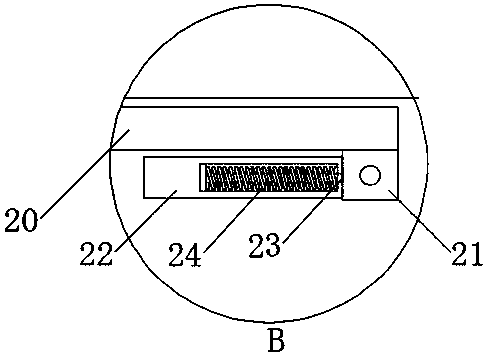

[0021] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a special tool for quickly removing ice coating on transmission lines, including a deicing box 1, a distance adjustment mechanism 2, an ice crushing mechanism 3, and a wire take-up mechanism 4. The inner wall of the deicing box 1 Slidingly connected with a distance adjustment mechanism 2, the top of the distance adjustment mechanism 2 is fixedly connected with an ice crushing mechanism 3, and one end of the outer side of the deicing box 1 is fixedly connected with a wire take-up mechanism 4, and the distance adjustment mechanism 2 is controlled by a distance adjustment mechanism. Lead screw 5, distance adjustment slider 6, first slider 7, second slider 8, first distance adjustment plate 9 and second distance adjustment plate 10, between the two sides corresponding to the inner wall of the deicing box 1 A distance-adjusting lead screw 5 is rotatably connected, and a distance-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com