Laminate structure with illumination function and mounting method thereof

A panel structure and function technology, applied in the field of disassembled formwork structure houses, can solve the problems of excessive weight of box-type mobile house components, complicated installation and disassembly, etc., and achieves the elimination of installation steps, strong turnover, and turnover. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

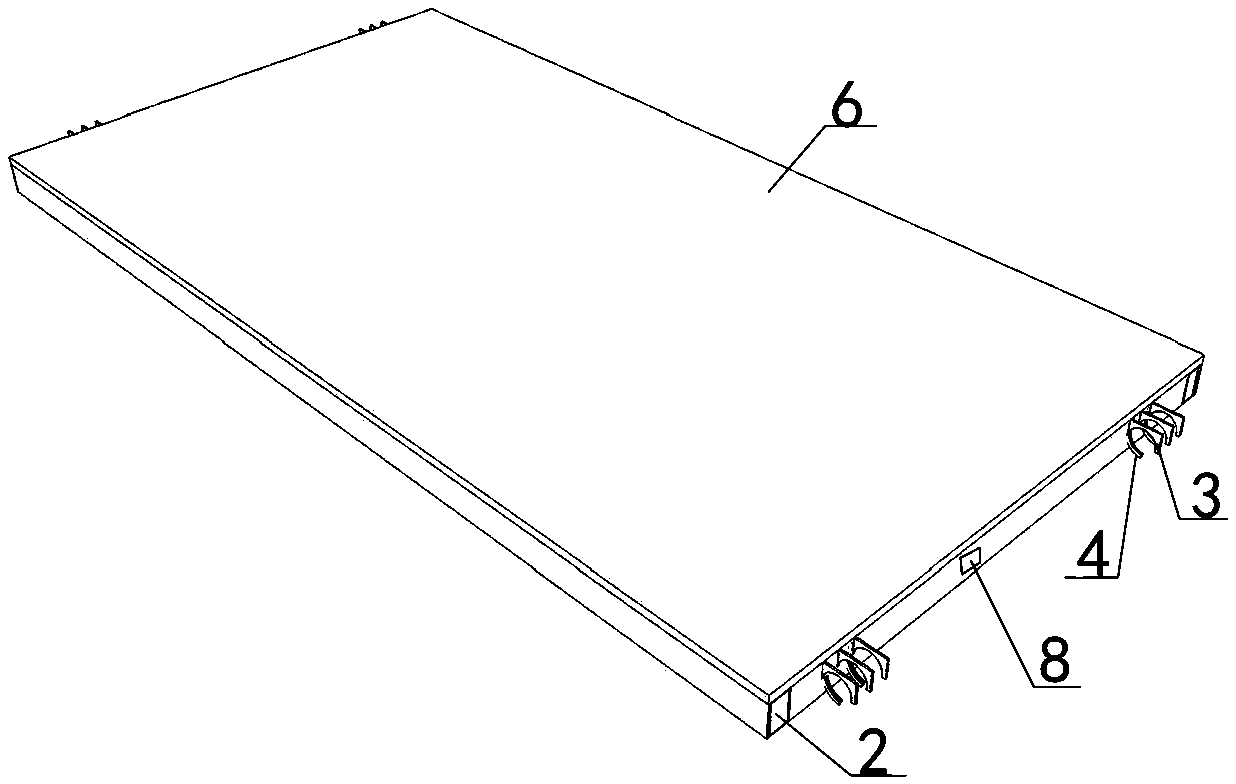

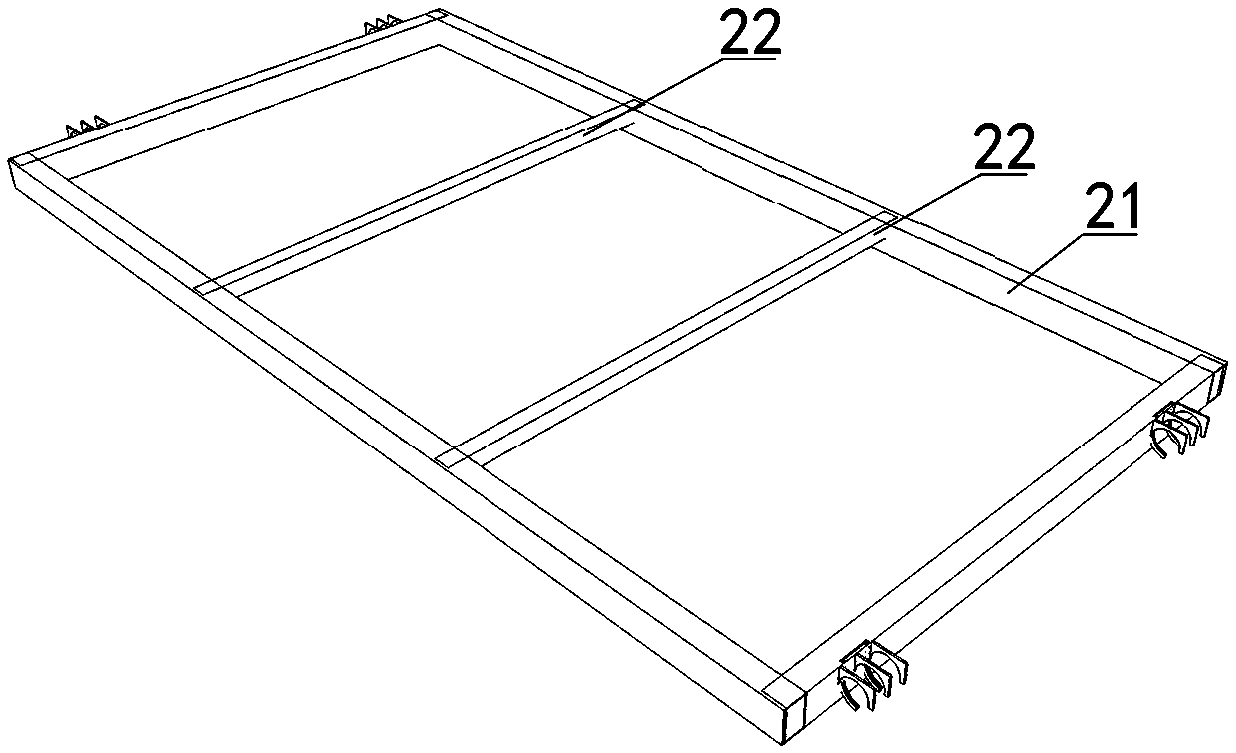

[0042] Embodiment two see Figure 4-5 As shown, the composite board is a bed board, and the difference from the first embodiment is that the upper side cladding material 6 is a rectangular panel, and a solid wood row skeleton board is used.

Embodiment 3

[0043] Embodiment three see Figure 6-7As shown, the composite panel is a ceiling panel, and also includes a lower side cladding material 7, the upper side cladding material 6 and the lower side cladding material 7 are PE tarpaulin, and the upper side cladding material 6 and the lower side cladding material 7 are closed. A PE tarpaulin jacket is formed. The PE tarpaulin jacket is directly sleeved on the support frame of the composite plate steel frame and is supported by its own tension, and the connecting end is closed by a hook and loop. The inner and composite plate steel frame supporting skeletons are filled with EPS thermal insulation material.

[0044] The independent lighting device is a flat panel headlight 10 directly embedded and fixedly connected to the lower side covering material 6, the flat panel headlight 10 is rectangular, and is centrally arranged on the center axis along the longitudinal direction of the lower side covering material.

Embodiment 4

[0045] Example 4 see Image 6 and Figure 8 As shown in the figure, the difference from the third embodiment is that the small local light 9 is embedded and fixed on the lower cladding material 6, the circuit of the light is connected to the access port 8, and the small local light 9 is centrally arranged close to the access port 8. End of underside cladding material for port 8.

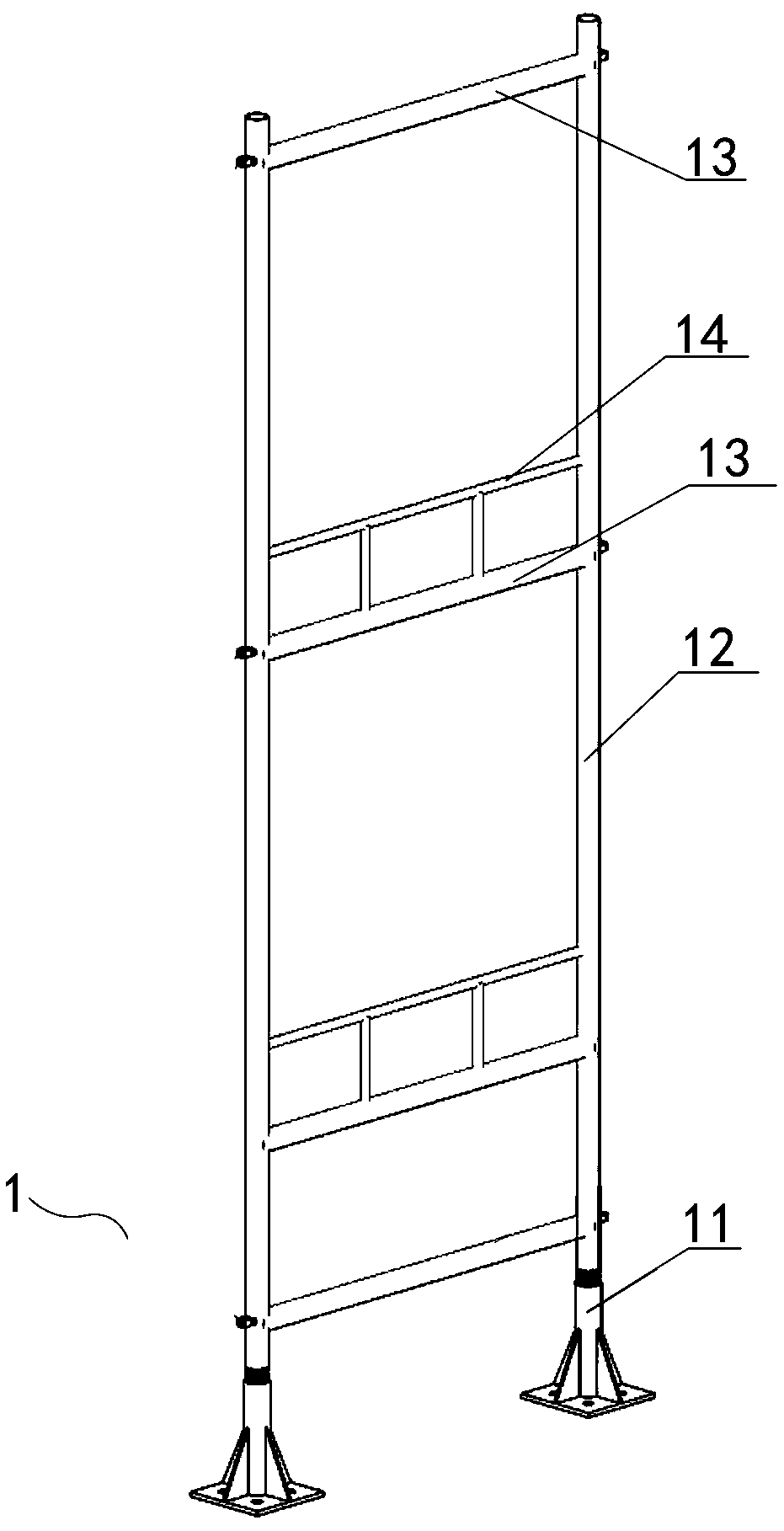

[0046] see Figure 9-10 As shown, the installation method of the laminate structure with lighting function is as follows. In this embodiment, one column and two rows of vertical supporting ladder-type parallel trusses are designed.

[0047] Step 1, design the size of the house and calculate the size and number of each component, process the vertical support ladder parallel truss 1 and the composite board in the factory, and set prefabricated holes for inserting the self-locking pin 4 on the end face of the composite board during processing , the self-locking pin 4 is inserted into the hole and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com