Jig for aluminum profile

A technology for aluminum profiles and fixtures, applied in the field of aluminum profile fixtures, can solve the problems of large electrolytic oxidation tank space, leaving traces on aluminum profiles, and damaging appearance effects, etc., and achieve the effects of simplified structure, convenient operation, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

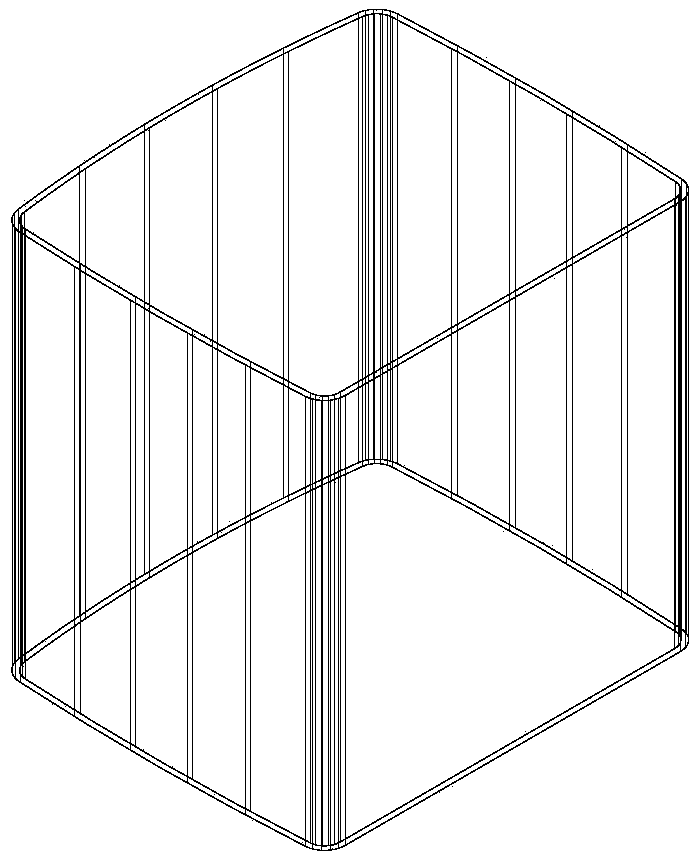

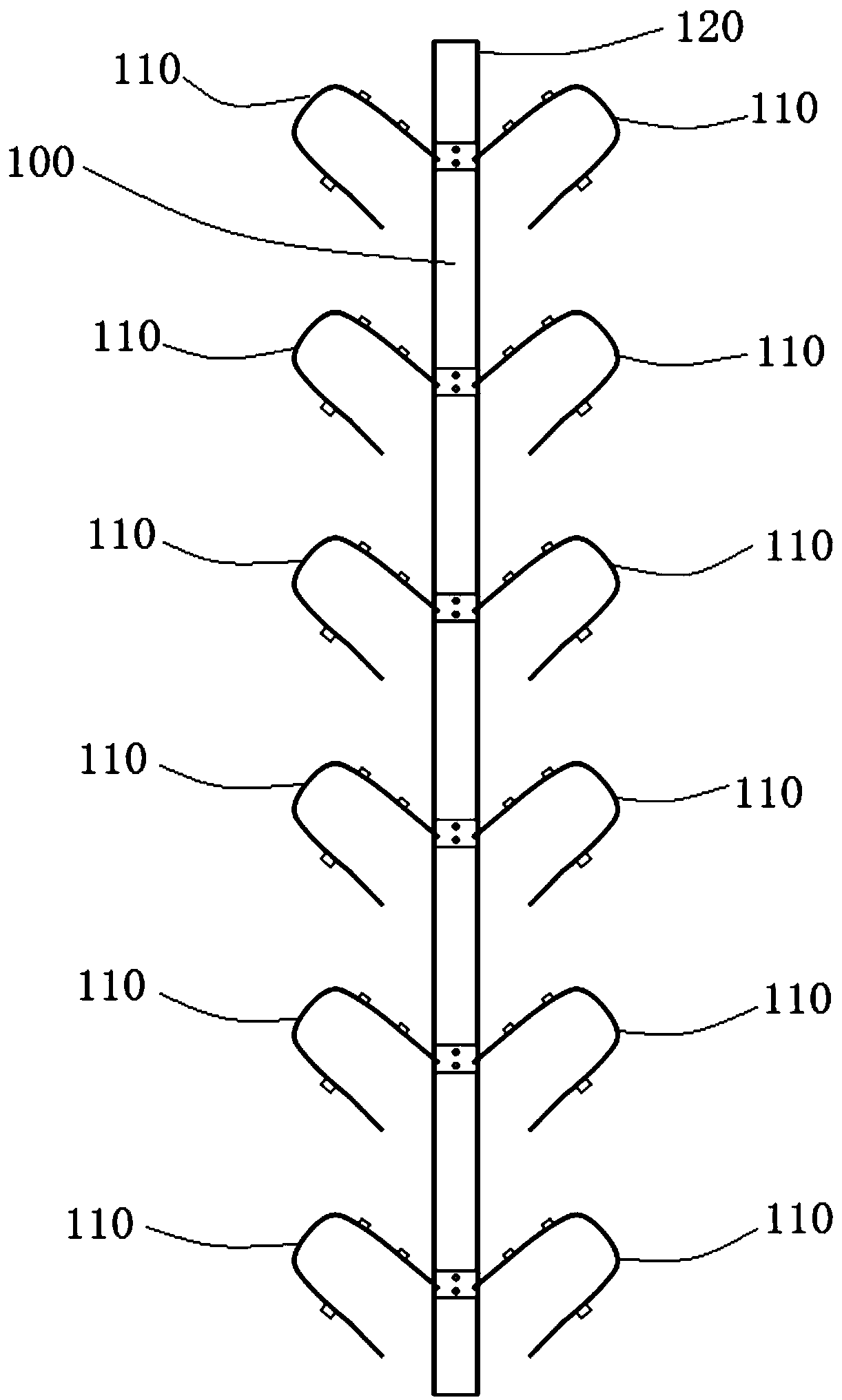

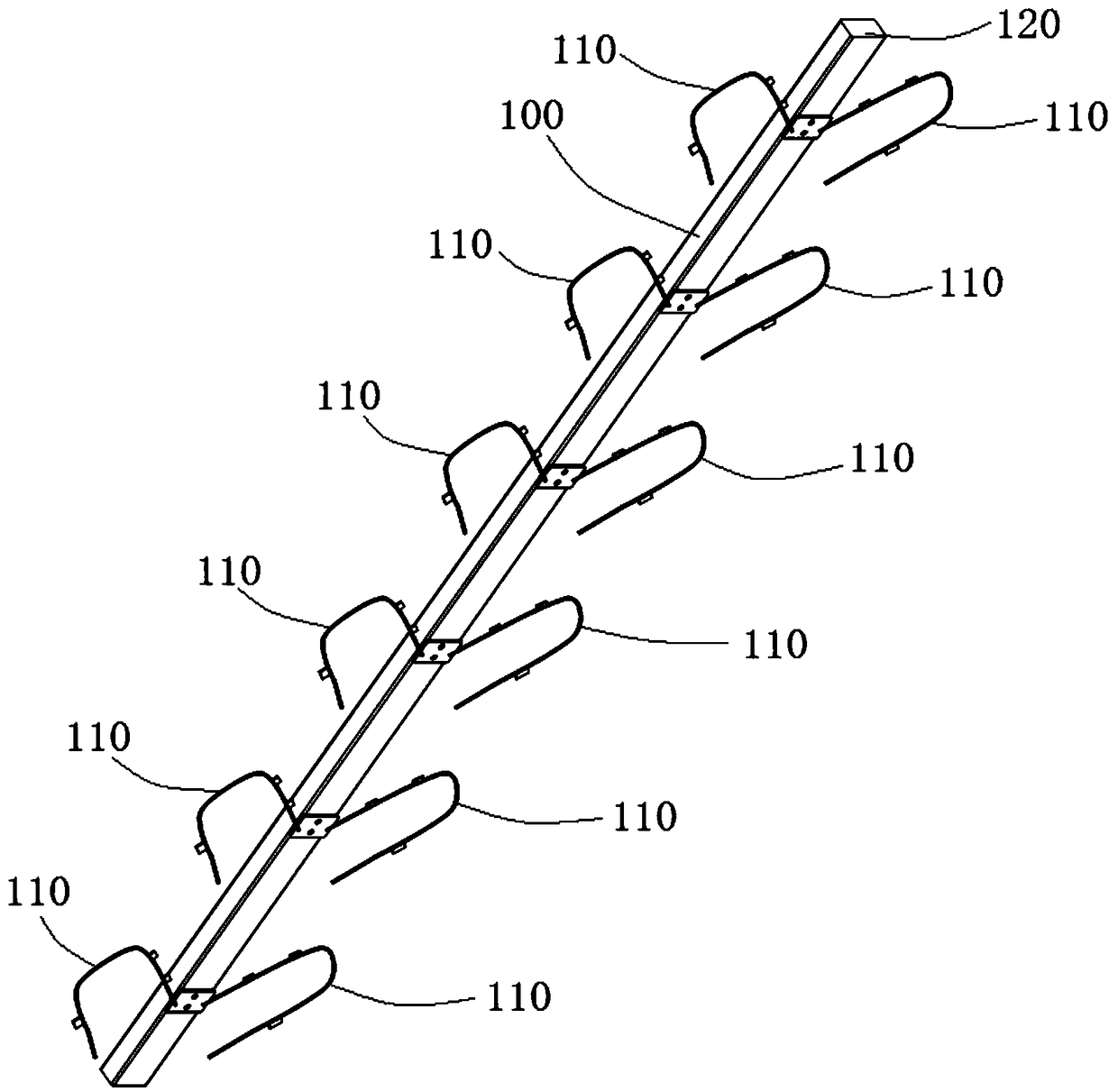

[0028] refer to figure 2 , in order to comply with the front view of the fixture for aluminum profiles in a preferred embodiment of the present invention, the fixture 100 is used for the oxidation process of aluminum profiles, including:

[0029] - hanger 110

[0030] The hanger 110 is at least one, U-shaped, and used for fixing hollow aluminum profiles. The hanger 110 can be made of aluminum, which can be consistent with the material of the aluminum profile, so as to reduce the contact resistance with the aluminum profile and achieve better electrical performance. combine Figure 4 It can be seen that the two arms of the U-shape have elastic recovery force and open outward, that is, the two arms of the U-shape are not parallel, but slightly open outward, forming a certain angle, so that the combination of the U-shape Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com