Clamping method and device for improving precision of circular trimmed shell type parts

A clamping device and a technology for parts are applied in the field of clamping methods and devices for machining and improving the accuracy of round edged shell parts, and achieve the effects of expanding the processing range, convenient manufacturing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

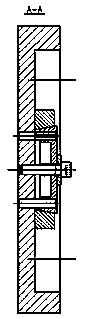

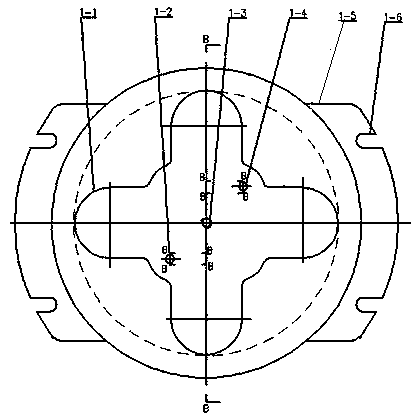

[0043] Such as figure 1 with figure 2 As shown in the figure, a clamping device for improving the accuracy of circular beveled shell parts includes a body 1, a surrounding inclined-plane pressing block 2 and a middle inclined-plane pressing block 3, the body 1 is provided with a cross-shaped groove, ten The 4 tops of the glyph grooves are all semicircular grooves 1-1; there are 4 oblique pressing blocks 2 around, as Figure 5 with 6 As shown, the surrounding inclined-plane pressing block 2 is a cylinder with a right-angled trapezoidal cross section, and the inclined surfaces of the four surrounding inclined-plane pressing blocks 2 are arranged in cross-shaped grooves, and each surrounding inclined-plane pressing block 2 corresponds to a semicircular groove 1 -1, and the length is less than the diameter of the semicircular groove 1-1; such as Figure 7 with8 As shown, the middle inclined-plane pressing block 3 is a square, and each of the four sides is provided with a wedge...

Embodiment 2

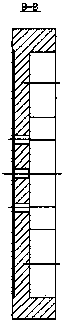

[0046] On the basis of Example 1, such as figure 1 As shown, the middle inclined-plane pressing block 3 is provided with a pressing plate 5 , and the screw 6 is threaded through the pressing plate 5 and the middle inclined-plane pressing block 3 and the body 1 .

[0047] Such as Figure 9 with 10 As shown, the pressure plate 5 is provided with an outwardly opening circular arc groove 5-1; the screw 6 transmits the pressure applied to the pressure plate 5 to the middle inclined plane pressing block 3 through the circular arc groove 5-1, and implements the Press tight. The use of circular arc grooves facilitates the adjustment of the force surface of the pressing plate on the middle inclined pressing block.

Embodiment 3

[0049] On the basis of embodiment 1 or embodiment 2, such as image 3 with Figure 4 As shown, the body 1 is disc-shaped, and fixed plates 1-5 are arranged symmetrically on both sides of the body 1, and two U-shaped grooves 1-6 that open outward are arranged on the fixed plates 1-5; The bottom surface of the body 1 is in contact with the machine tool plane, and the clamping device of the present invention is connected with the machine tool through the U-shaped groove 1-6 on the fixing plate 1-5, so that the clamping device of the present invention is fixed on the machine tool. A threaded hole 1-3 is provided at the center of the body 1, and a first positioning hole 1-2 and a second positioning hole 1-4 of the body are symmetrically arranged around the threaded hole 1-3. Such as Figure 7 with Figure 8 As shown, the middle inclined-plane pressing block 3 is provided with a square groove 3-5, and the opening direction of the square groove 3-5 is opposite to the body 1; a via...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com