Compression mold with overflow holes and fitting and preparation scheme thereof

An overflow hole and mold technology, applied in the field of molding molds, can solve the problems of decreased tensile strength, affected surface smoothness, structural changes, etc., and achieve the effects of increased tensile strength, uniform thickness, and no change in structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

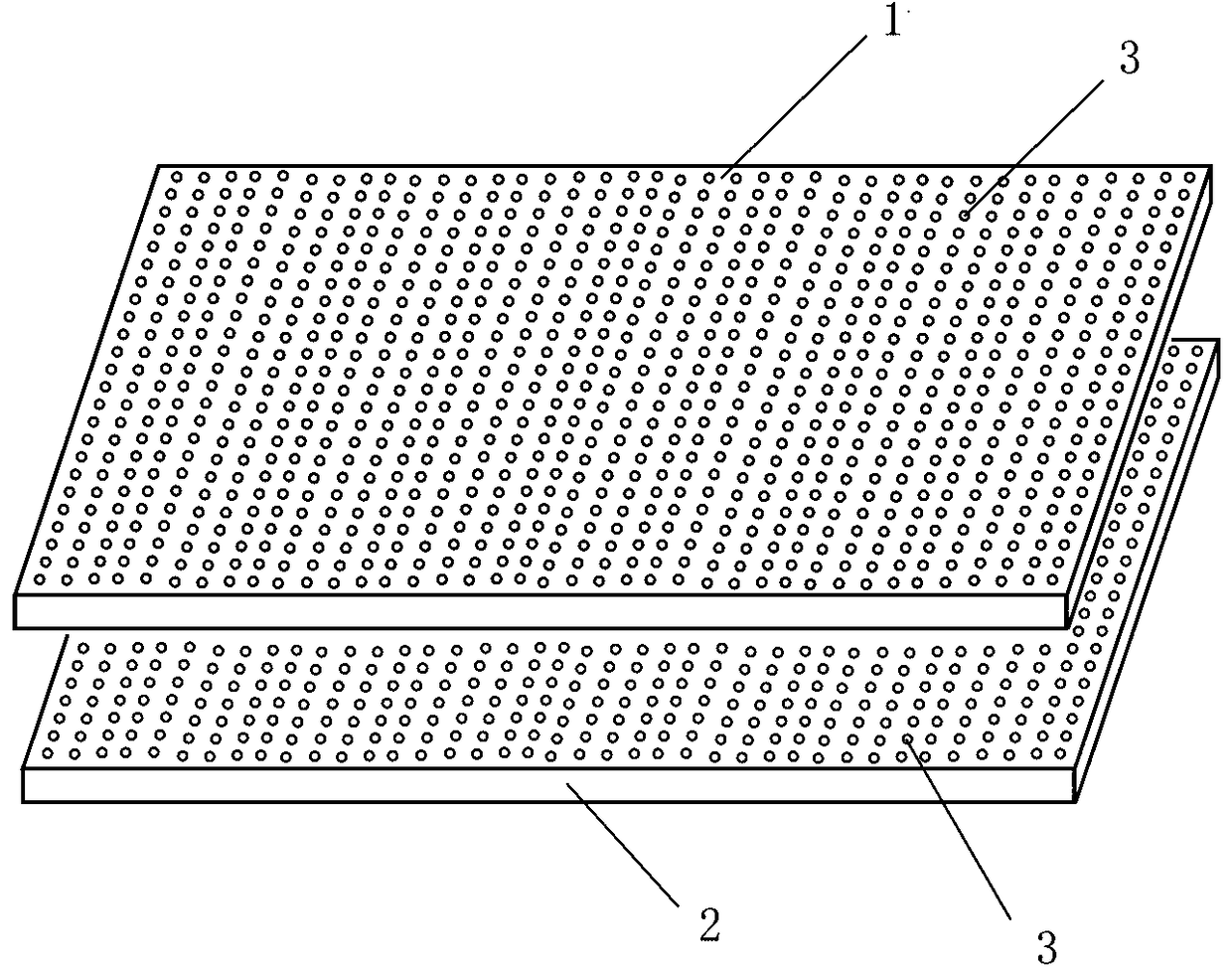

[0020] Molding molds and accessories with overflow holes and their preparation plan, including the upper mold 1 and the lower mold 2 of the mold, from the surface of the laminated object in the mold to the outside of the mold, adopt the method of mechanical drilling or laser perforation, and set the distribution evenly Several small overflow holes 3 are suitable for flat, oval and shell molds. For example, in some irregular parts of the shell mold, the overflow holes 3 provided may be uneven. For the parts mentioned above, first lay a fixed metal wire interwoven fabric along the inner wall of the mould. The metal wire interwoven fabric can be fixed on the outer periphery of the upper mold 1 and the lower mold 2, and a small number of small points on the inner wall, and then lay a fixed fiber interwoven fabric. The fixing method can be adopted Adhesively fix it on the outer periphery of the mold edge and a small number of small points on the inner wall, and then lay and fix the...

Embodiment 2

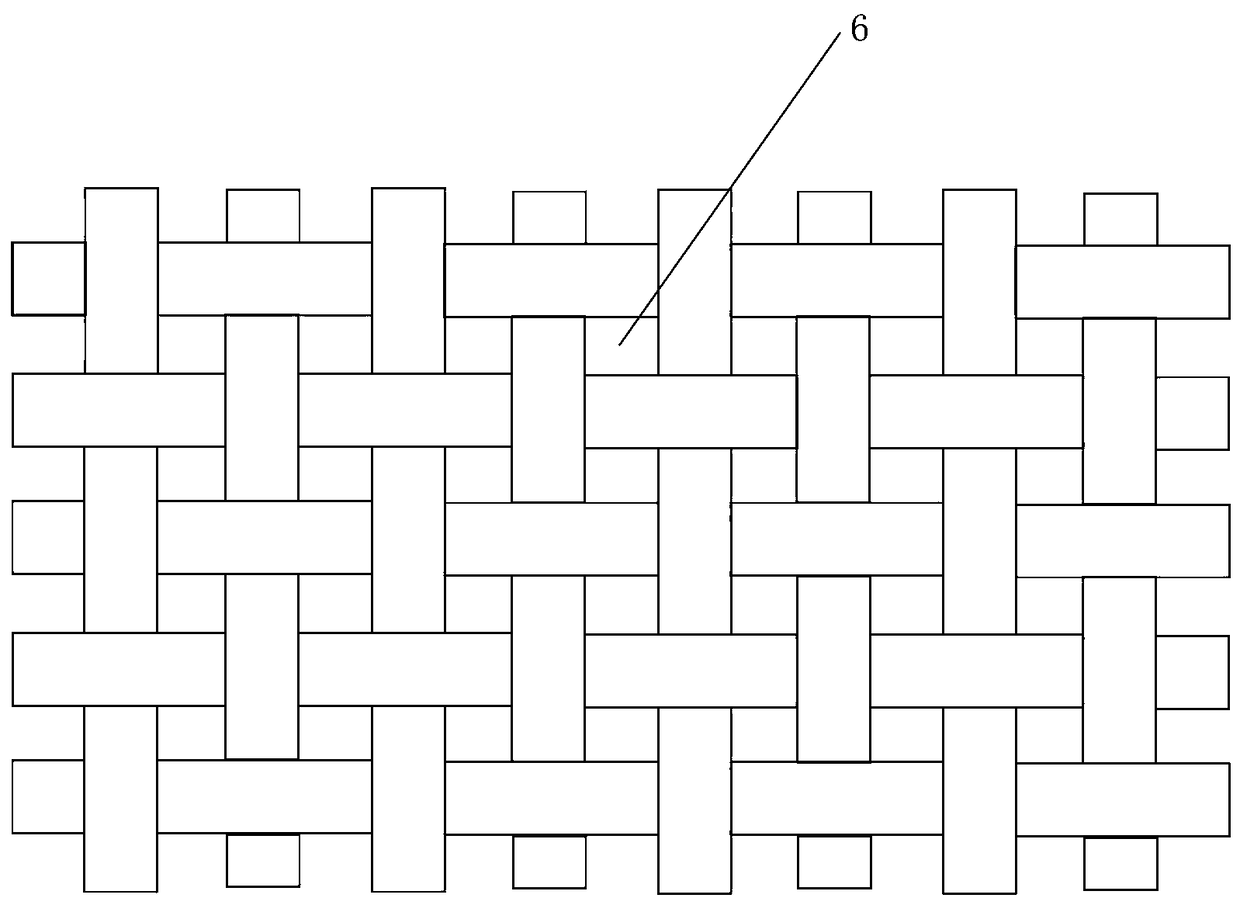

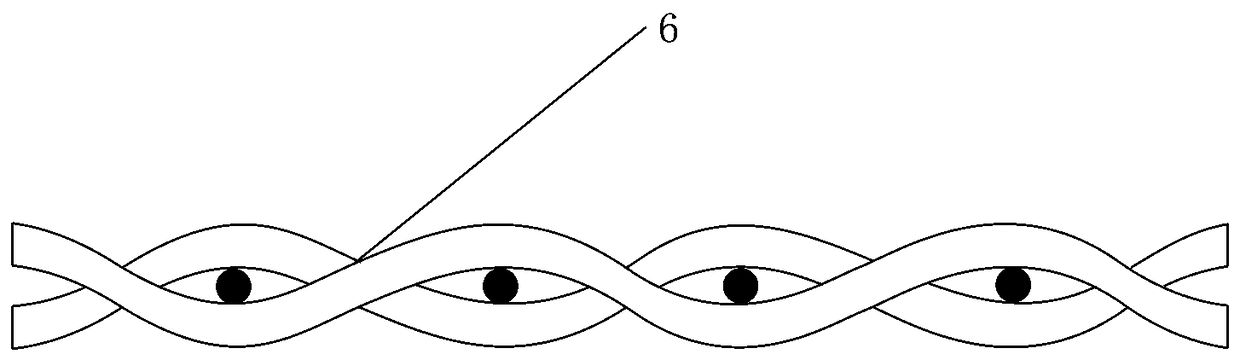

[0022] The upper mold 1 and the lower mold 2 of the molding die can be used without overflow holes 3, and according to the requirements of the pressed object and the number of layers, the thickness is different, and the upper mold 1 or the lower mold 2 without overflow holes can also be used; Only install accessories on the inner wall of the mold. The inner wall of the mold is firstly laid with a single layer of fixed metal wire or a double layer of metal wire in the warp and weft direction, then laid with a fixed metal wire interwoven fabric, then laid with a fixed fiber interwoven fabric, and then laid a fixed fiber felt, and then placed in During the pressing process after the pressed object, the liquid first overflows from the gap 6 of the fiber felt surface on the pressing surface, and then flows to the gap 6 of the fiber interwoven cloth, most of which flow to the metal wire interwoven fabric, and a small part flows to the mold along the interlayer The edge, then flows to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com