Continuous pultrusion and hot pressing device of cap-shaped stringer of thickness-variable composite material and molding method

A composite material and hot pressing device technology, applied in the field of composite material processing, can solve the problems of inconsistent thickness of profiles, inability to meet application requirements, inability to apply uniform pressure on hat-shaped long trusses of variable thickness, etc., and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

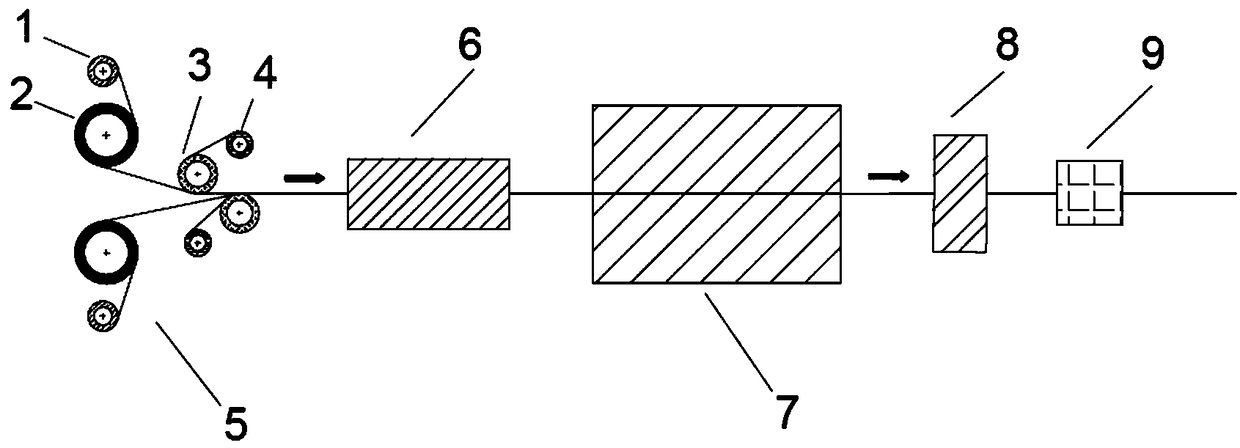

[0040] Such as figure 1 In the continuous pultrusion forming process shown in the figure, the prepreg is stacked by the unwinding module 5, and then sequentially passes through the preforming module 6, the hot pressing module 7, the traction module 8 and the cutting module 9, and is processed into a finished product of a set length;

[0041] The unwinding module 5 includes: several prepreg reels 2, backing paper rewinding reels 1, rollers 3 and release material reels 4; the laid-up prepregs are unrolled from the prepreg reels 2, and the backing paper is isolated Rewinding by the winding shaft 1, multiple sets of prepreg layers are pasted by multiple rollers 3, and the release material 4 is laid on the upper and lower surfaces of the final prepreg layer group;

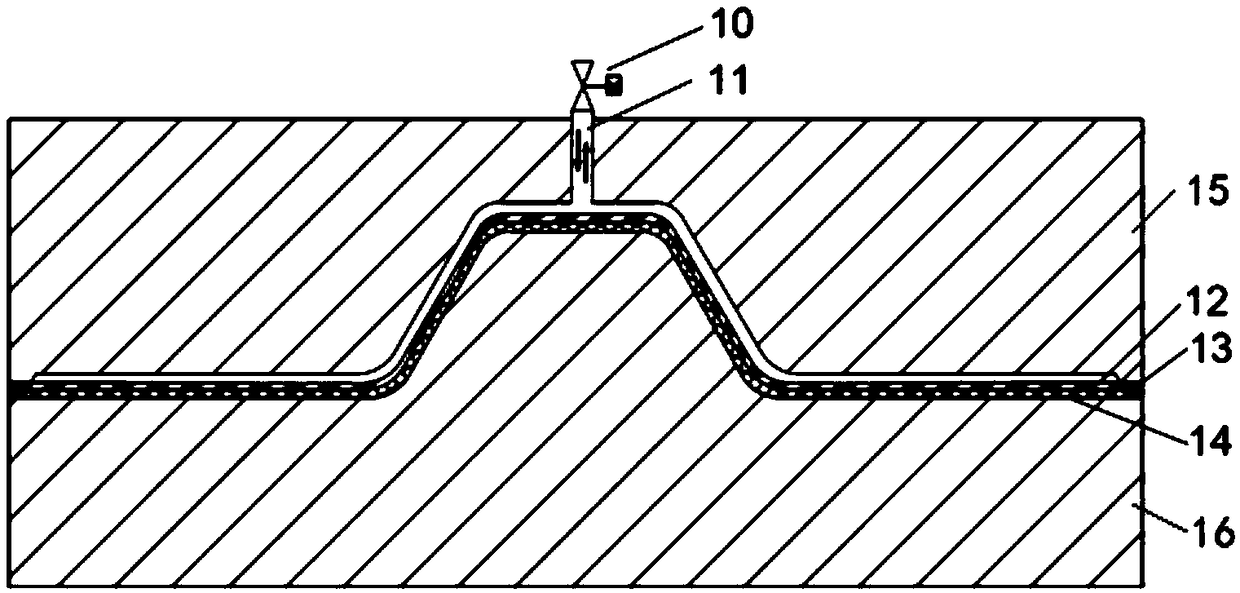

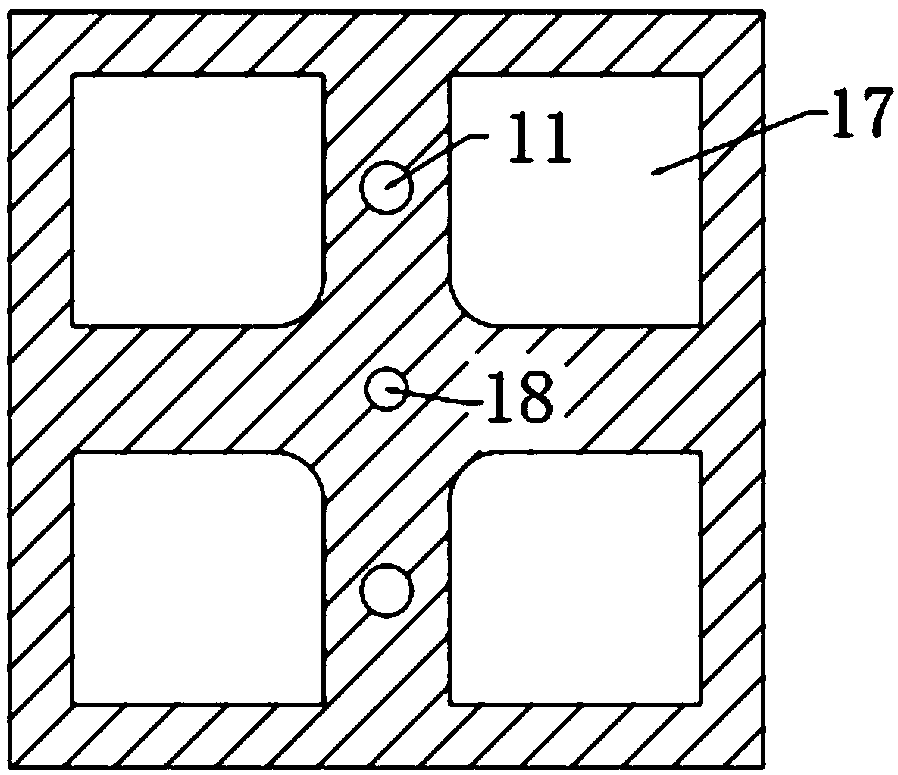

[0042] After paving, the final prepreg layer group enters the preforming module 6, and is graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com