Coiled material winding tension real-time detection and regulation system

A real-time detection and adjustment system technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of easy oscillation of the system, high price, low tension control accuracy, etc., to reduce costs and low prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Coil 2 winding tension real-time detection and adjustment system, including:

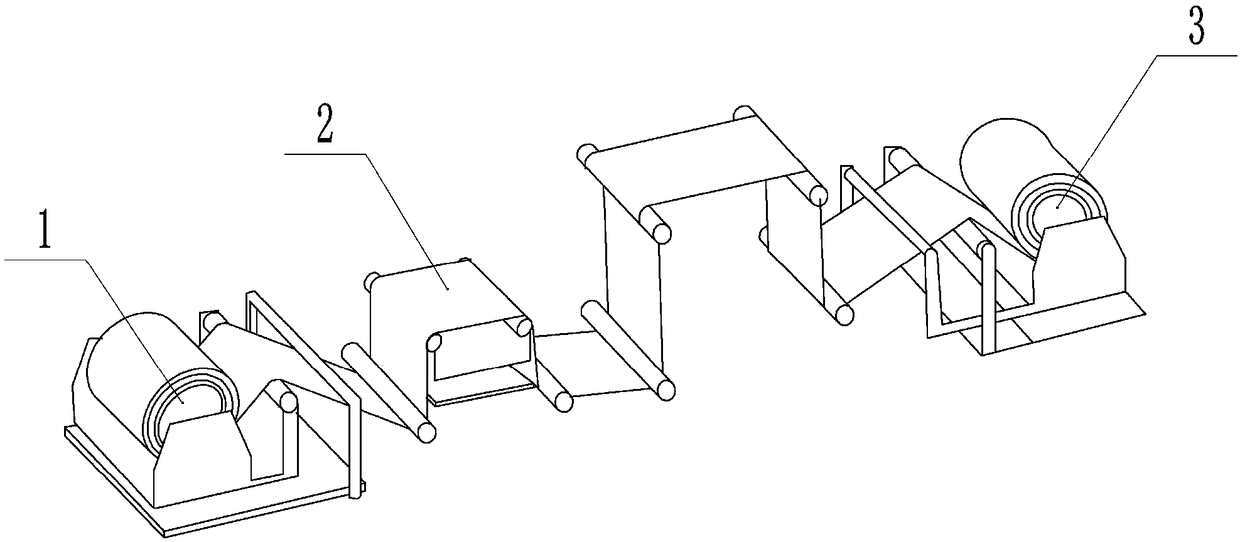

[0026] Tension adjustment mechanism, such as figure 1 As shown, the tension adjustment mechanism includes a driving roller 3, a driven roller 1, a first servo motor and a second servo motor (the first servo motor and the second servo motor are in figure 1 Not shown in), the output shaft of the first servo motor is fixedly connected with the driving roller 3, and the output shaft of the second servo motor is fixedly connected with the output shaft of the driven roller 1.

[0027] The tension detection module is used to detect the tension of the coil 2 between the driving roller 3 and the driven roller 1. The tension detection module includes a Hall sensor, and the Hall sensors are respectively arranged beside the driving roller 3 and the driven roller 1. The sensor is used to detect the number of rotations of the driving roller 3 and the driven roller 1 respectively, and then the tension dete...

Embodiment 2

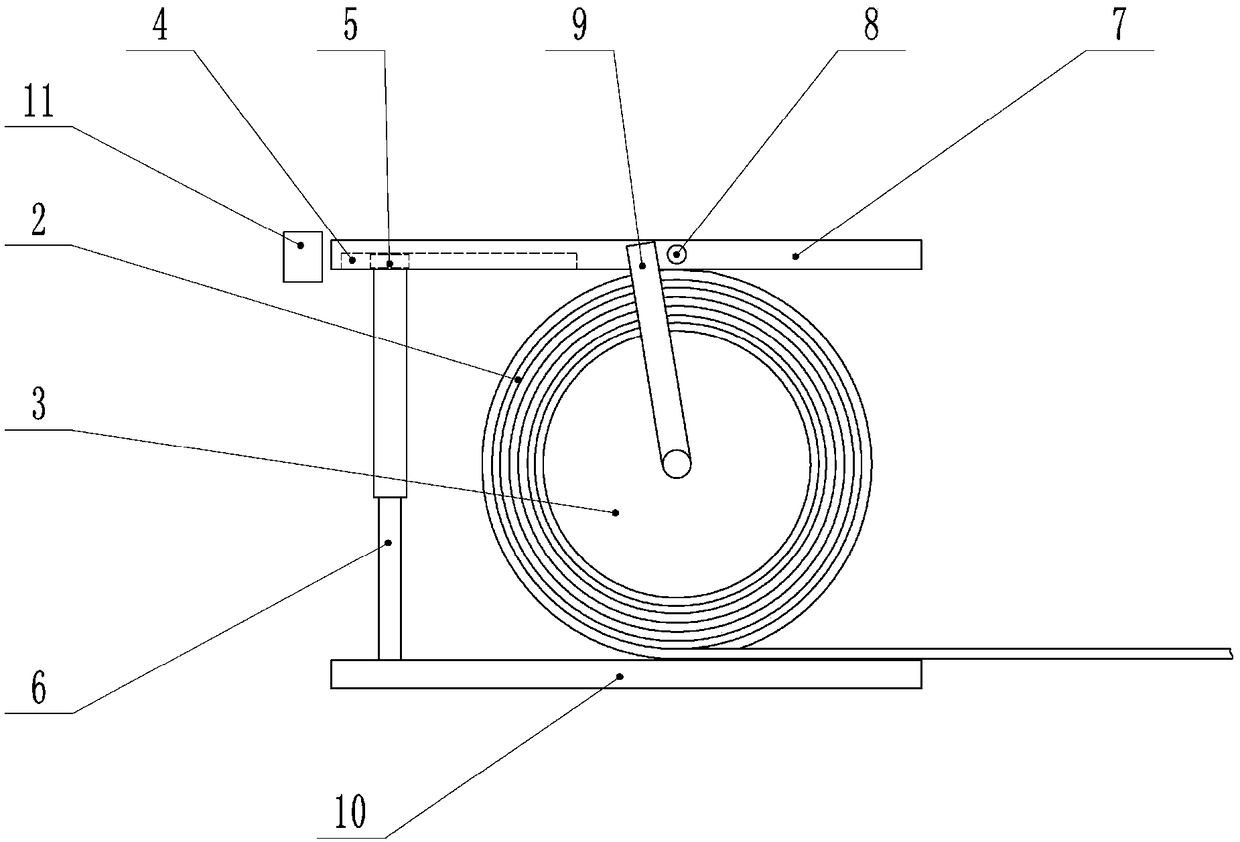

[0031] like figure 2 As shown, the difference between the second embodiment and the first embodiment is that in the second embodiment, the active roller 3 is provided with a winding thickness detection mechanism of the coil 2, and the thickness detection mechanism of the coil 2 includes: a mounting frame, on which the first A measuring plate 7, the left end of the first measuring plate 7 is fixed with a telescopic rod 6, the top of the telescopic rod 6 is provided with a second measuring plate 10, the first measuring plate 7 and the second measuring plate 10 are arranged in parallel, and the second measuring plate 10 is provided with There is a chute 4, a slide block 5 is slidably connected in the chute 4, and a return spring is connected between the slide block 5 and the left end of the chute 4 (the return spring is in the figure 2 not shown in), the slider 5 and the top of the expansion rod 6 are welded; the first measuring plate 7 is fixed with a retaining rod 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com