Rail vibration damping fastener

A technology of damping fasteners and rails, which is applied in the field of rail transit, can solve problems such as bulky pressurizing devices, increased maintenance workload and capital investment, and unrealistic problems, so as to simplify installation and maintenance operations, eliminate hidden dangers of driving safety, and improve The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

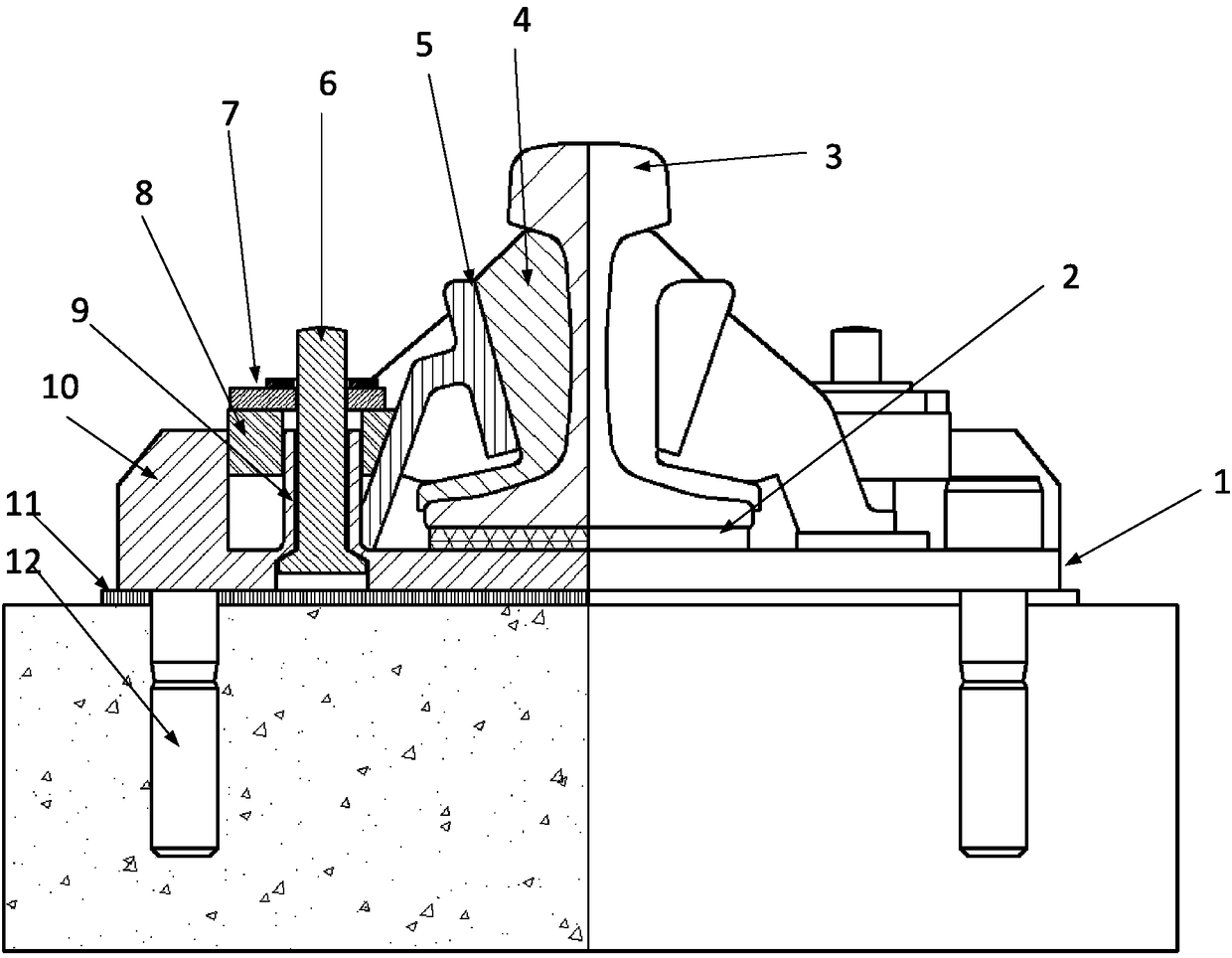

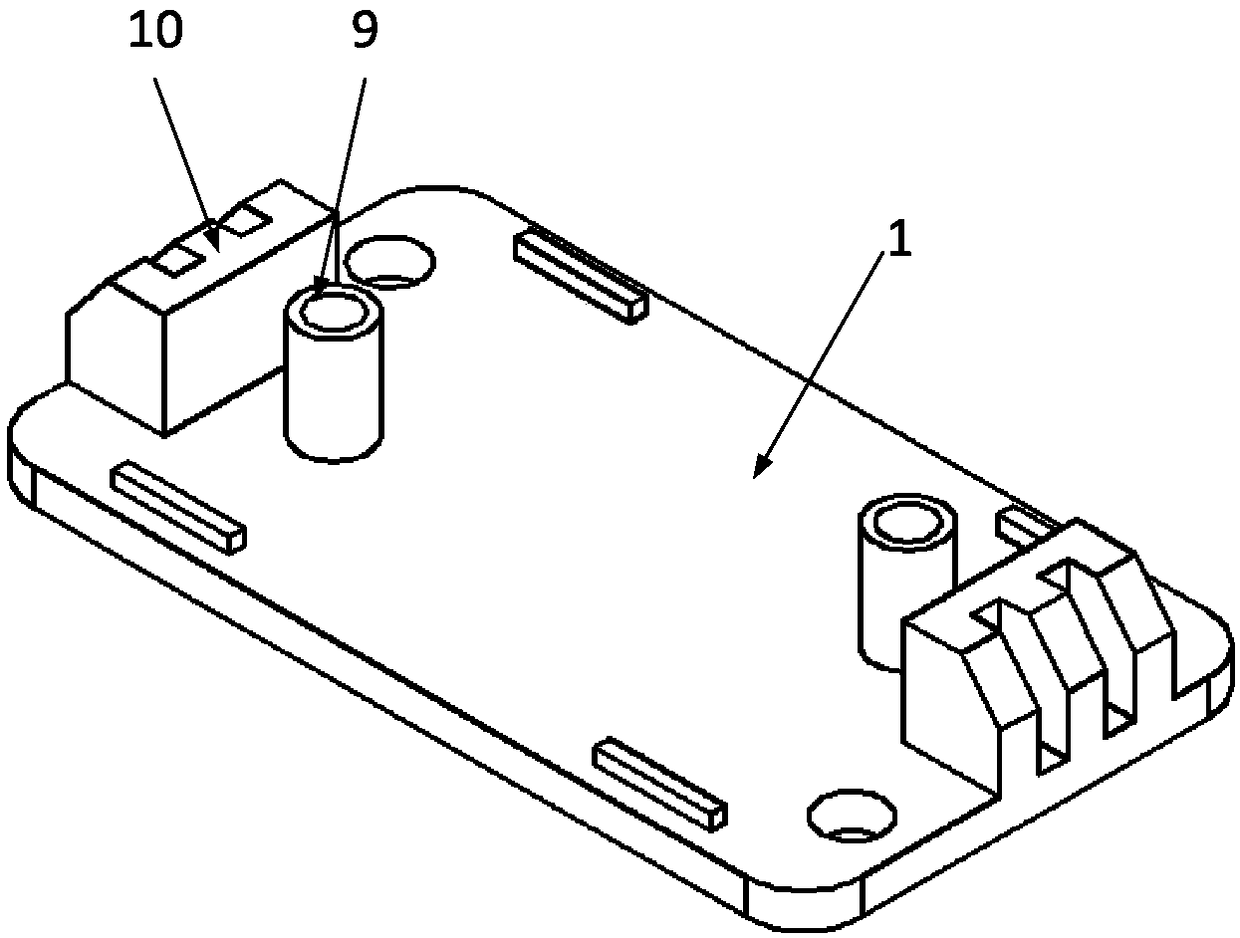

[0060] Such as figure 1 As shown, the first embodiment of the present invention provides a rail vibration damping fastener, which may include a backing plate 1, an elastic body 4, a supporting plate 5, a positioning block 8 and a fastening mechanism; the backing plate 1 is provided with a positioning column 9, The positioning block 8 is provided with a first through hole, and the positioning block 8 is sleeved on the outside of the positioning column 9 through the first through hole; wherein the positioning block 8 can slide along the positioning column 9, that is, the positioning block 8 can be adjusted. Vertical position; the above-mentioned positioning column 9 is preferably arranged vertically on the backing plate 1, that is, the positioning block 8 can move along the positioning column 9 in a vertical direction.

[0061] In this embodiment, the above-mentioned fastening mechanism includes fasteners and a locking cover plate 7. The fasteners are connected to the positioning co...

Embodiment 2

[0080] The second embodiment of the present invention provides a rail vibration damping fastener. The main structure is similar to the first embodiment, and also includes a backing plate, an elastic body, a support plate, a positioning block and a fastening mechanism; for the record of the main structure, please refer to the foregoing The detailed record in the first embodiment; here is to illustrate the difference between the two.

[0081] Such as Picture 9 As shown, in this embodiment, the fasteners are bolts, and the upper part of the positioning column 9 is provided with internal threads; the bolts pass through the locking cover plate and are tightened on the internal threads of the positioning column 9. Wherein, the above-mentioned bolts may be the hexagonal bolts 14 shown in the figure, or bolts of other structural forms.

[0082] In the specific operation, the above-mentioned positioning post 9 can be set as a through hole structure, and the inner surface of the through hol...

Embodiment 3

[0084] The third embodiment of the present invention provides a rail vibration damping fastener. The main structure is similar to the first embodiment, and also includes a backing plate, an elastic body, a support plate, a positioning block and a fastening mechanism; for the record of the main structure, please refer to the foregoing The detailed record in the first embodiment; here is to illustrate the difference between the two.

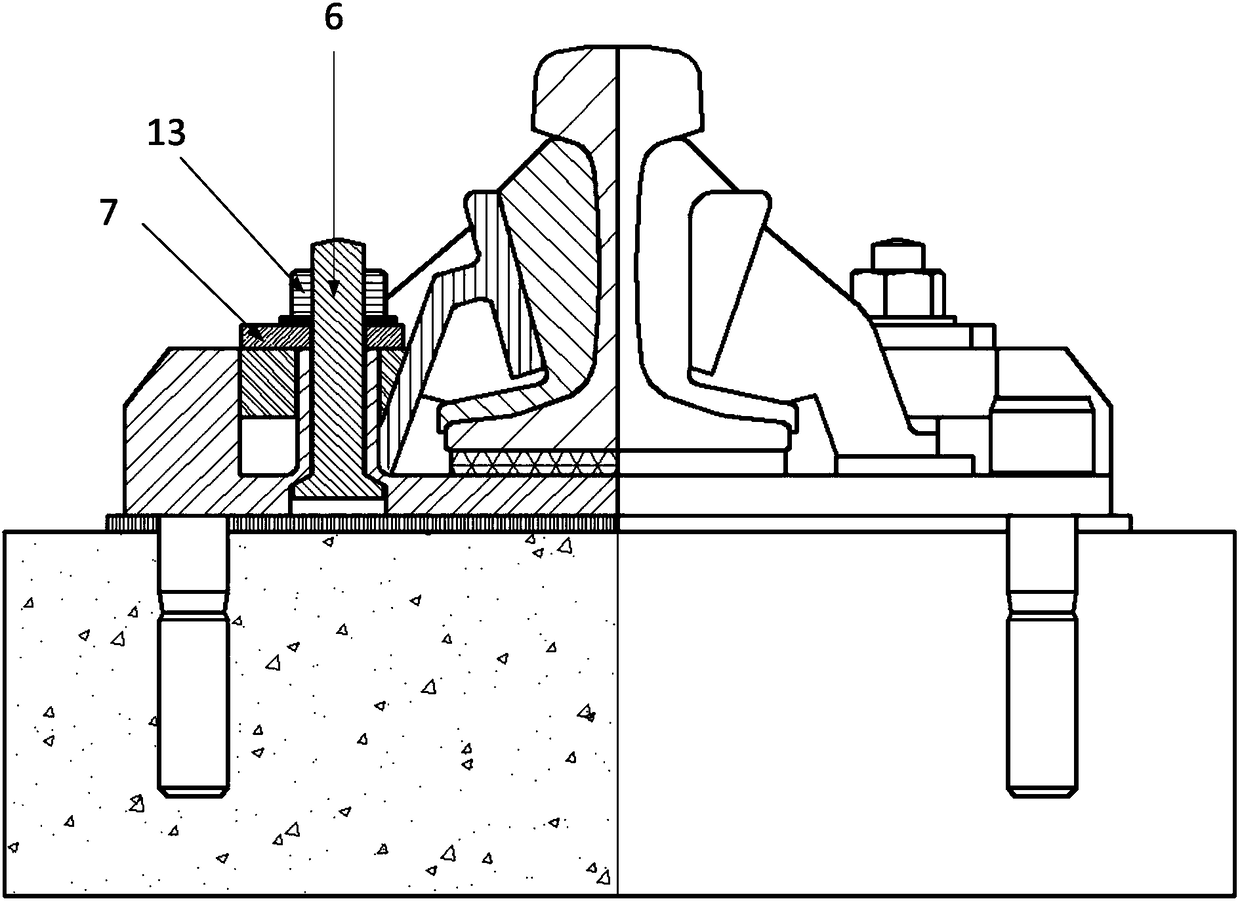

[0085] Such as Picture 10 As shown, in this embodiment, the fastener is a nut 13, and the upper part of the positioning column 9 is provided with an external thread; the nut 13 is screwed on the outer bolt of the positioning column 9, and the lower surface of the nut 13 presses and locks the cover plate. The aforementioned nut 13 can be a common hexagonal nut or a nut of other structural forms.

[0086] In the specific operation, a certain length of external thread can be opened on the upper part of the positioning column 9. After the positioning block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com