A road garbage cleaning and collecting device

A collection device and garbage technology, applied in road cleaning, cleaning methods, construction, etc., can solve problems such as threats to personal safety, low efficiency of road cleaning and garbage cleaning, and achieve the effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

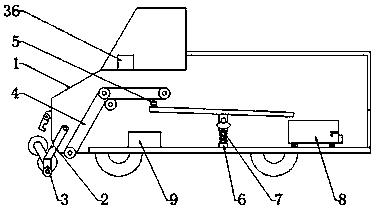

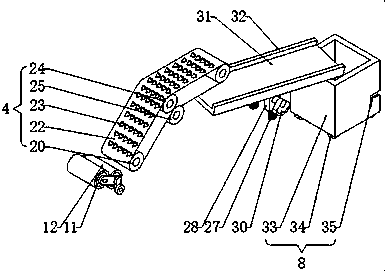

[0033] Embodiment 1: as Figure 1-9 Shown, a kind of road garbage cleaning and collecting device of the present invention comprises car body 1, also includes:

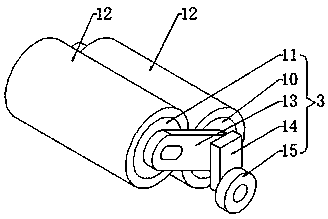

[0034] The movable frame 2 placed at the bottom of the front of the vehicle body 1, the top of the movable frame 2 is hinged with the vehicle body 1, and the bottom of the movable frame 2 is provided with a cleaning mechanism 3 for cleaning the ground and collecting garbage. The cleaning mechanism 3 includes a first electric roller 10 and the second motorized roller 11, and the outside of the first motorized roller 10 and the second motorized roller 11 are sleeved with a brush cover 12, and the first motorized roller 10 and the second motorized roller 11 rotate in opposite directions , the first motorized roller 10 and the second motorized roller 11 can be supported by the movable frame 2, and direct contact and friction between the first motorized roller 10 and the ground can be avoided, and the first motorized roller...

Embodiment 2

[0041] Example 2, such as figure 1 and 3 As shown, the surface of the front of the car body 1 is provided with a hook for accommodating the movable frame 2, and the middle part of the movable frame 2 is provided with a hook groove matching the hook, and the first electric roller 10 and the second electric roller 11 Both ends are provided with connecting plates 13, and the outsides of the two connecting plates 13 are provided with supporting plates 14, and the bottoms of the two supporting plates 14 are provided with movable wheels 15, and the movable frame 2 is rotationally connected with the connecting plate 13 top, and the movable frame One end of 2 makes the movable wheel 15 contact the ground through the connecting plate 13 and the supporting plate 14. The hook and the hook groove can facilitate the staff to store the movable frame 2. The movable wheel 15 can make the distance between the first electric roller 10 and the ground It is stable and avoids friction of the firs...

Embodiment 3

[0042] Example 3, such as Figure 4 As shown, the middle parts of the two ends of the second electric roller 11 are provided with rotating rods 16, and the outsides of the two rotating rods 16 are sleeved with movable blocks 17, and the two rotating rods 16 are rotationally connected with the inside of the movable block 17, and the movable One side of the block 17 is slidably connected with the slide bar 18, the slide bar 18 is positioned in the groove on one side of the connecting plate 13, and the top of the slide bar 18 is sleeved with a first spring 19, through the movable block 17, the slide bar 18 and the first The spring 19 not only improves the cleaning and collecting effect of the first motorized roller 10 and the second motorized roller 11, but also protects the second motorized roller 11 to prevent the first motorized roller 10 and the second motorized roller 11 from Damage occurs when a foreign object gets stuck in it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com