Mini cryogenic lng storage tank

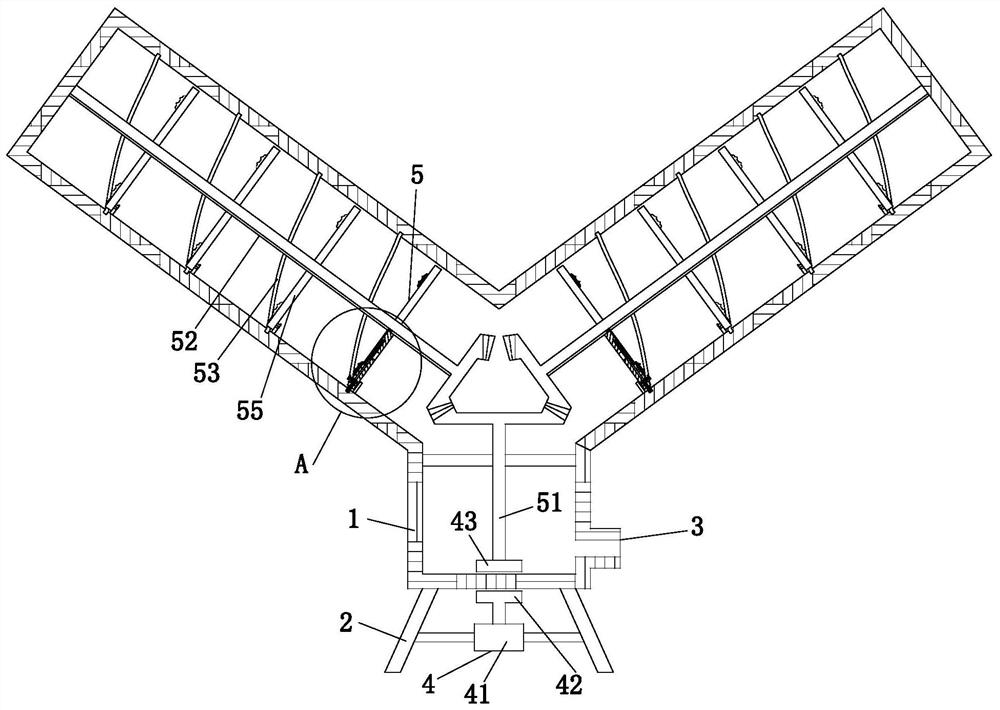

A low-temperature, mini technology, applied in the field of pressure vessels, can solve the problems of difficulty in using a horizontal single tank to store liquid LNG, easy residual liquid LNG in the tank, high cost, etc., to reduce impact, reduce resistance, and avoid residual effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

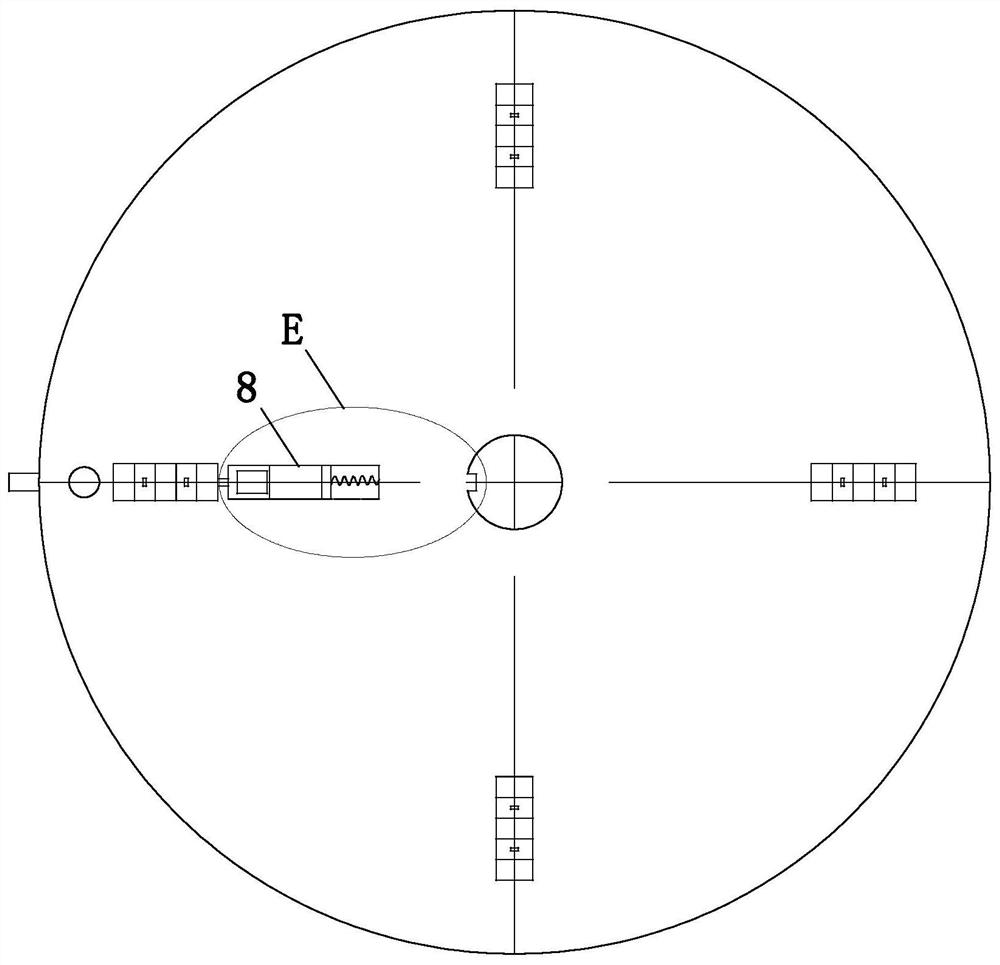

Method used

Image

Examples

Embodiment approach

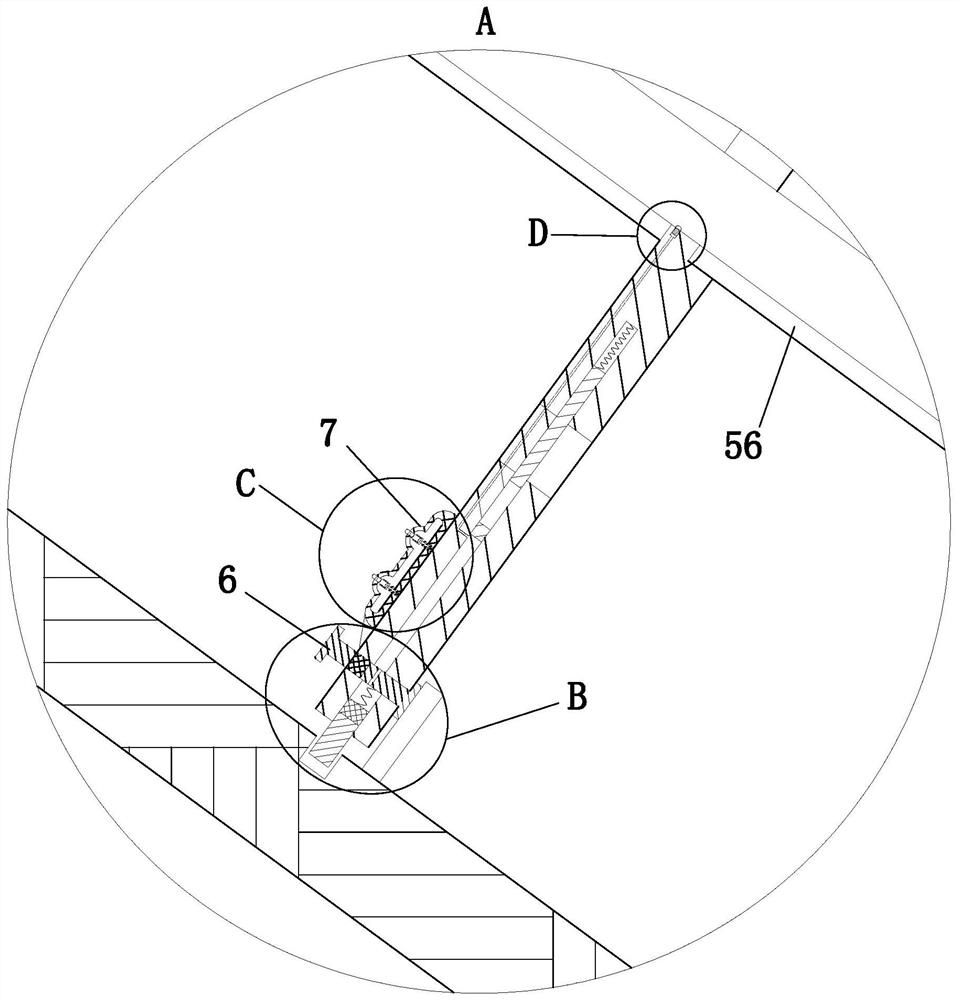

[0029] As an embodiment of the present invention, the support assembly 72 includes a buffer wheel 75, a support wheel 76, a support column 77 and a support hole 78; the protrusion 73 is provided with a buffer wheel 75, and the buffer wheel 75 can rotate around an axis ; The bottom of the buffer cavity 74 is provided with a support hole 78 corresponding to the buffer wheel 75, the support hole 78 is covered with a support column 77, and a spring is provided between the support hole 78 and the support column 77; the support column 77 is located in the support hole One end of 78 exteriors is provided with bracing frame, and bracing frame is provided with support wheel 76; Described buffer wheel 75 is elastic rubber material, and buffer wheel 75 contacts with disc 55 and can offset impact force, and buffer wheel 75 cooperates with support wheel 76, Sufficient supporting force can be provided; the support column 77 cooperates with the spring to make the supporting column 77 have a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com