Energy-saving and environment-friendly bored pile construction method

A technology of bored piles and construction methods, which can be applied to sheet pile walls, foundation structure engineering, construction, etc., and can solve problems such as collision with hole walls, shaking of steel cages, and construction difficulties, so as to improve energy conservation and environmental protection, and increase the lower speed , to reduce the effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

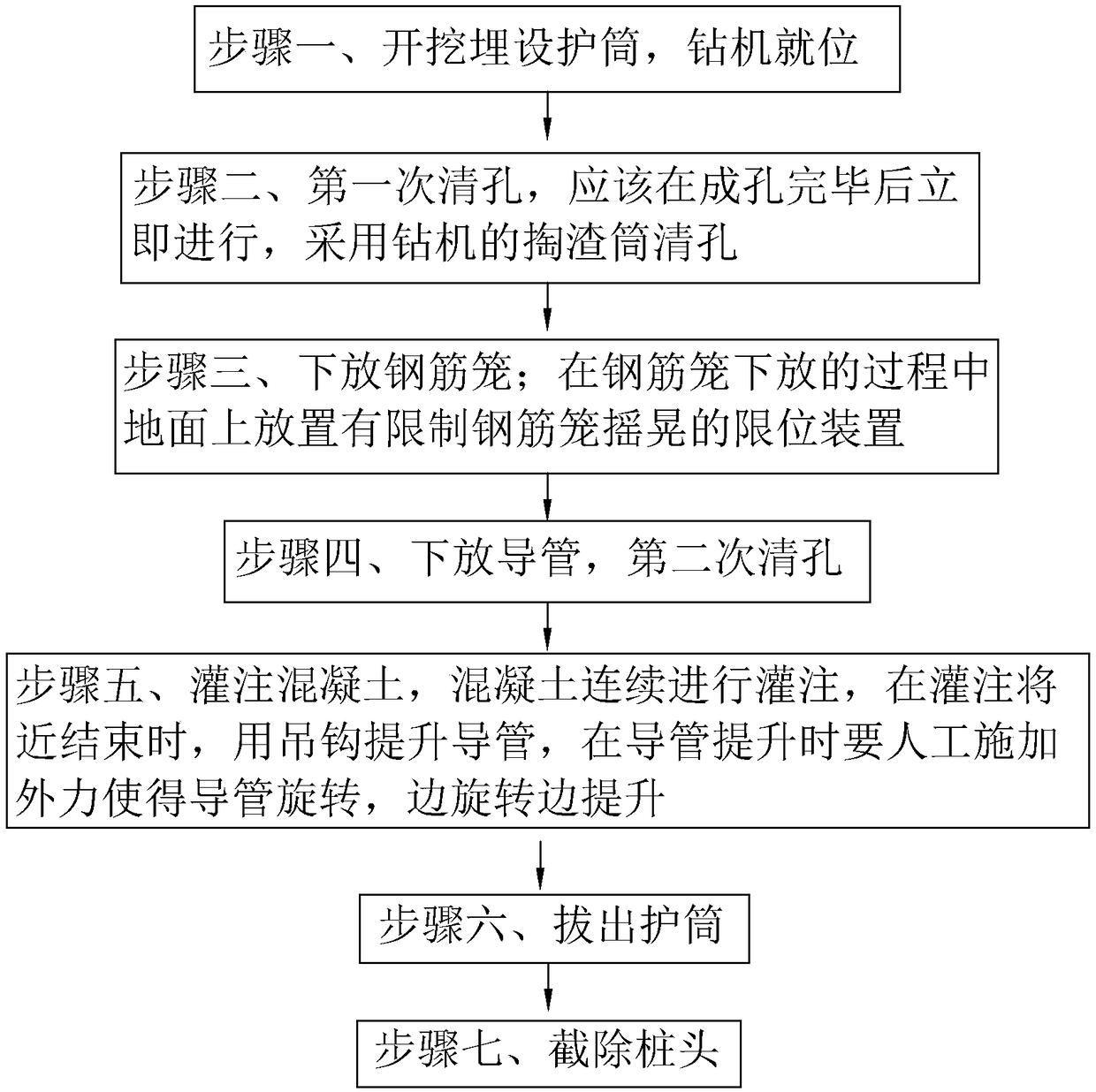

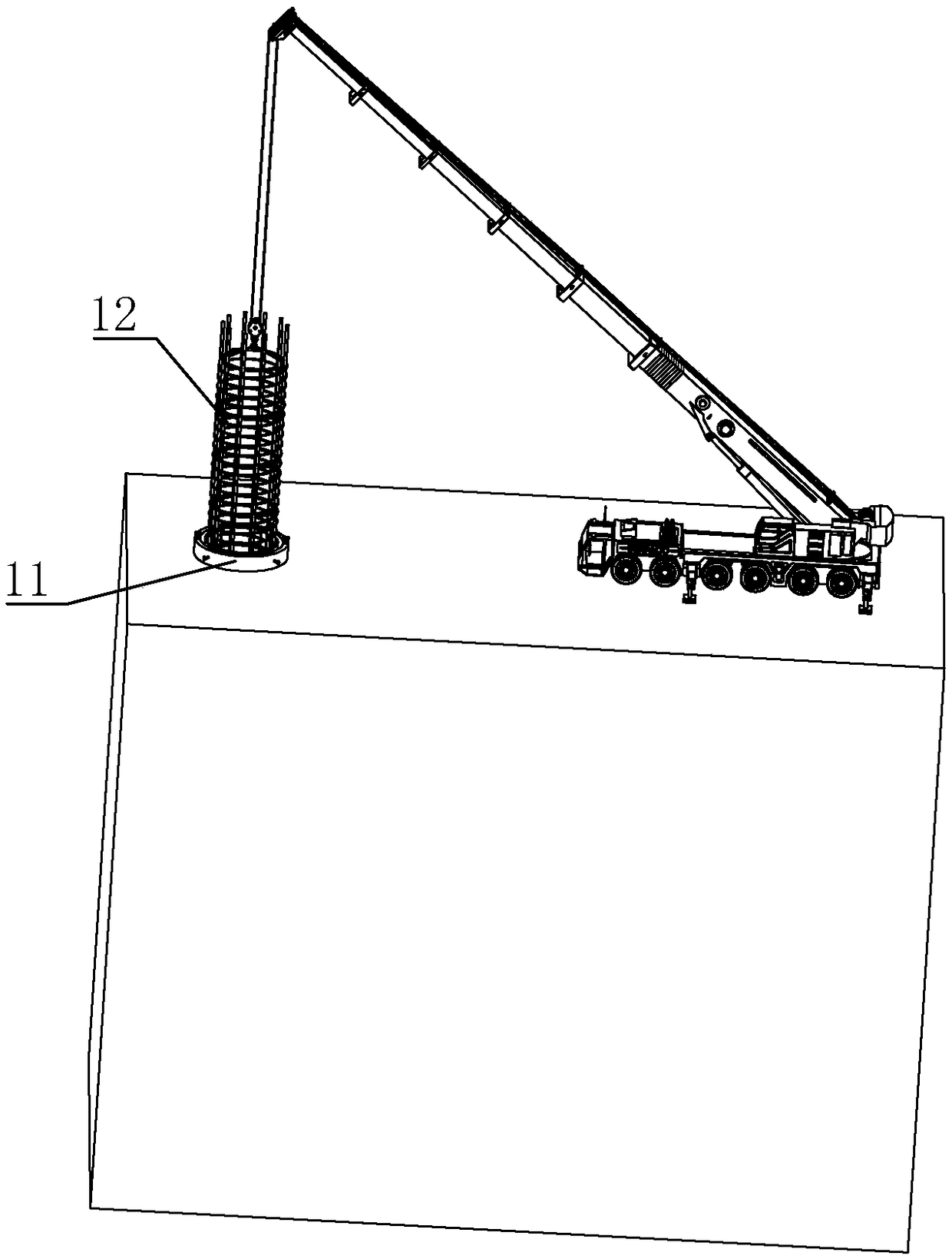

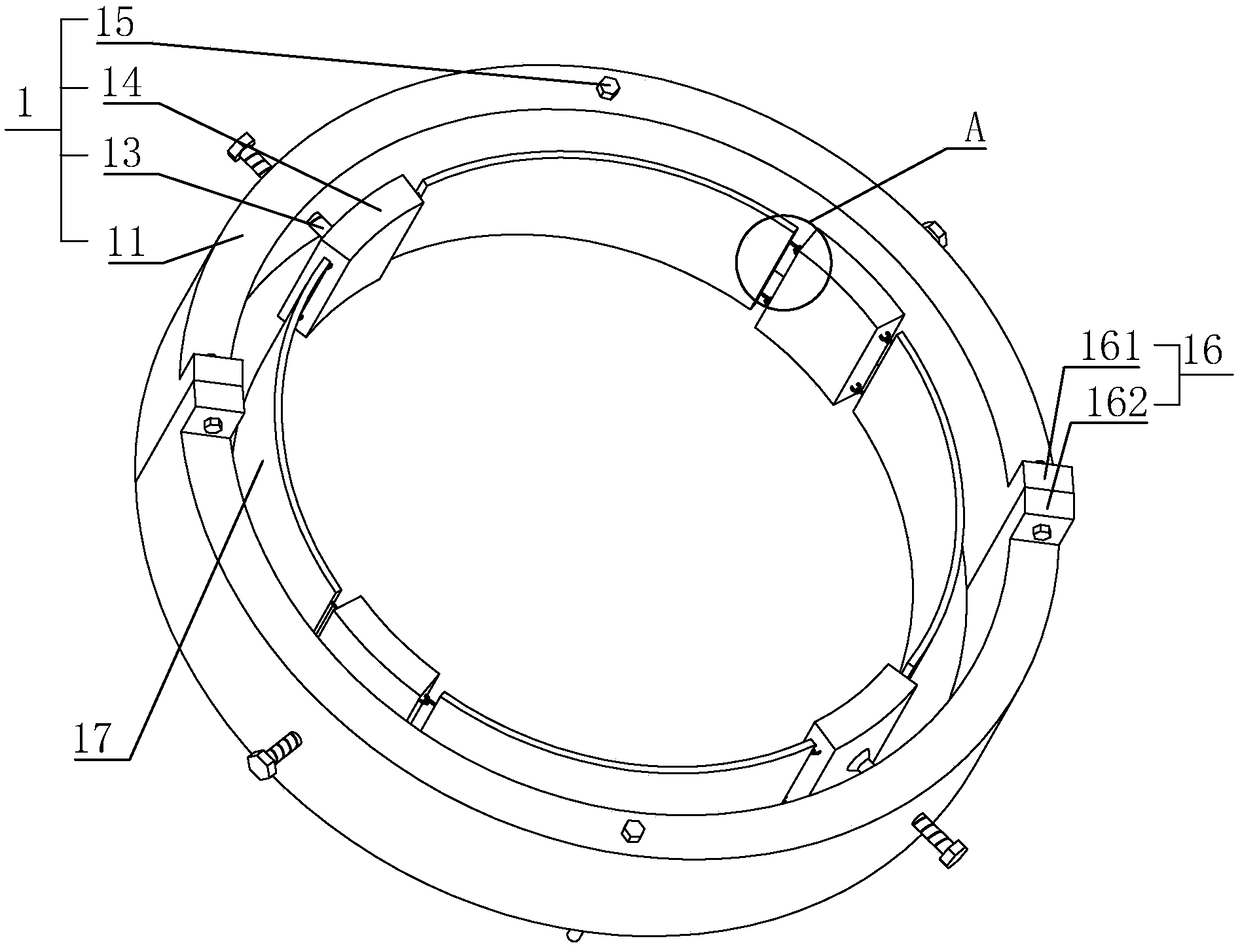

[0040] An energy-saving and environment-friendly bored pile construction method, such as figure 1 , including the following steps,

[0041] Step 1. Excavate and bury the casing, and put the drilling rig in place. The inner diameter of the casing should be 200-400mm larger than the diameter of the pile. When the drilling rig starts drilling, it should drill at a slow speed. After the drill bit has completely entered the formation, it can speed up the drilling. During the construction of the drilling rig, it should be ensured that the mud surface should not be lower than the bottom of the casing of the drilling rig to ensure the stability of the hole wall; the mud is provided by the mud in the mud circulation system; at this time, the mud circulation system reduces the discharge of mud in the drill hole to the construction site, This further affects the environment of the construction site. In addition, when there is a lack of mud in the borehole, the mud circulation system prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com