Oil pipe perforator and method for preventing throttling mouth from choking

A technology for a hole punch and an oil pipe, applied in the field of hole punch, can solve the problems of high manufacturing cost, complex structure, inconvenient use, etc., and achieve the effects of low manufacturing cost, smooth forward and reverse movement, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

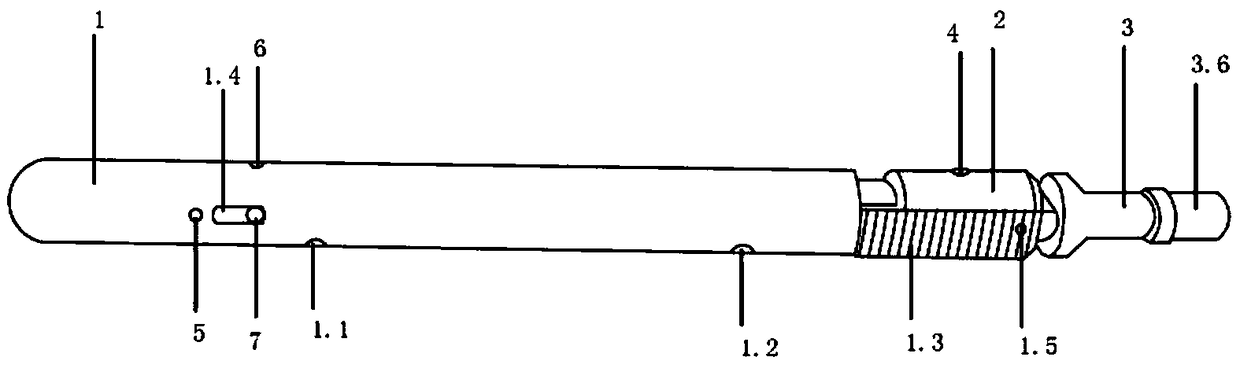

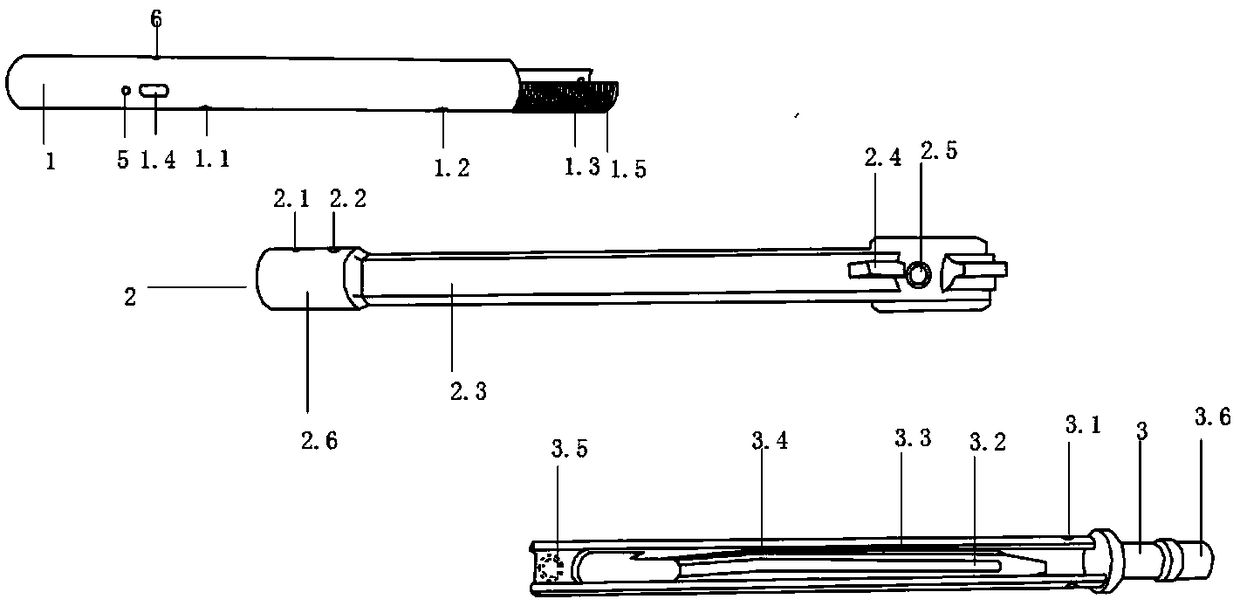

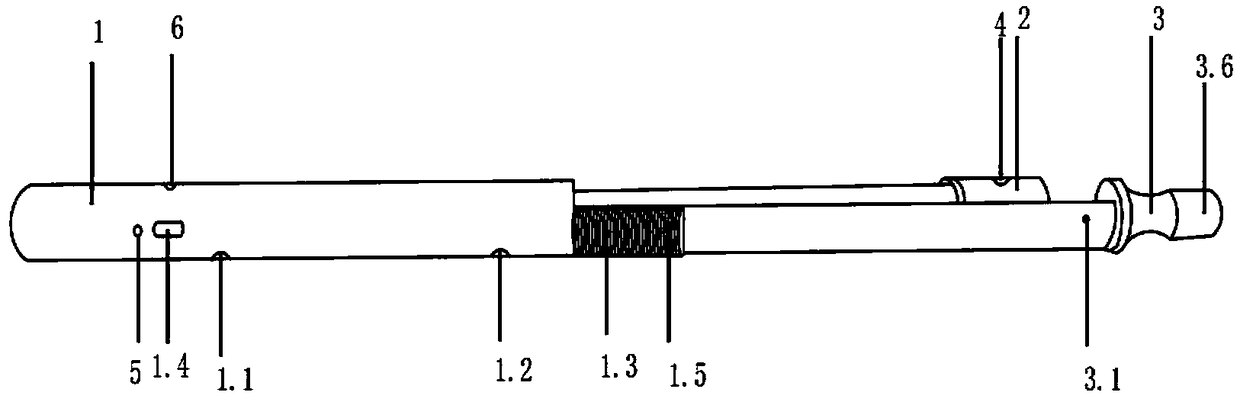

[0021] Example 1, such as Figure 1-Figure 5As shown, the oil pipe puncher includes a cylinder body 1, a body 2, a bracket 3, a punch 4 and a positioner 10; the outer end of the cylinder body 1 is provided with a semicircular slip 1.3, and the side of the cylinder body 1 The second positioning hole 1.2, the second shear pin hole 5 of the cylinder and the sliding hole 1.4 of the positioning pin are set on the wall; the connecting terminal 3.6 is set at the outer end of the support 3, and the support 3 body is a semicircular groove shape. 3 There are slideway 3.2, fixed slideway 3.3 and tapered slope 3.4 in the body groove, that is, the structure is inclined upward and then downward after reaching the highest point; the slideway 3.2 is set in the middle position to accommodate the sliding boss 2.4 Wherein it slides; the tapered slope 3.4 is arranged on both sides of the slideway 3.2; the fixed chute 3.3 is arranged on both sides of the slideway 3.2, and the both sides of the pun...

Embodiment 2

[0022] Example 2, such as Figure 4 As shown, the punch includes a punch head 4.1 and a punch seat 4.2, which are fixedly connected, preferably integrally cast or forged; the two sides of the punch seat 4.2 are symmetrically provided with a first inclined table surface 4.2.1 and a second inclined table surface 4.2 .2; the inclination direction of the first inclined table surface 4.2.1 and the second inclined table surface 4.2.2 are the same, and the upper and lower positions are opposite. The fixed chute 3.3 is also conical in parallel with the conical inclined surface 3.4, and the lower surface of the punch seat 4.2 is in contact with the conical inclined surface 3.4. Therefore, in the process of pulling the bracket 3 outward, because of the existence of the first inclined platform 4.2.1, the punch 4 is easier to slide relative to the tapered inclined surface 3.4, and will not be stuck; and after the drilling is completed, take out the oil pipe For the hole puncher, when it ...

Embodiment 3

[0023] Example 3, such as Figure 1-Figure 3 As shown, on the basis of the above-mentioned technical solution, the first positioning hole 1.1 is also arranged on the same side of the second positioning hole 1.2 and the positioning pin sliding hole 1.4 on the cylinder 1; the positioning pin 7 passes through the positioning pin hole 2.2 and the positioning The pin sliding hole 1.4 is provided, and can slide up and down along the positioning pin sliding hole 1.4. A fastening screw hole 6 is arranged vertically on the cylinder body 1 relative to the sliding hole 1.4 of the positioning pin. The middle part of the positioning pin 7 is an inner hexagonal structure. The inner hexagonal structure position in the middle is used to fix the positioning pin 7 to prevent the positioning pin 7 from running out or rotating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com