Energy-saving pressure-combining well head fracturing device

A wellhead device and fracturing technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of reducing safety risks, shortening construction period, economic losses, etc., to reduce safety risks and shorten construction period. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

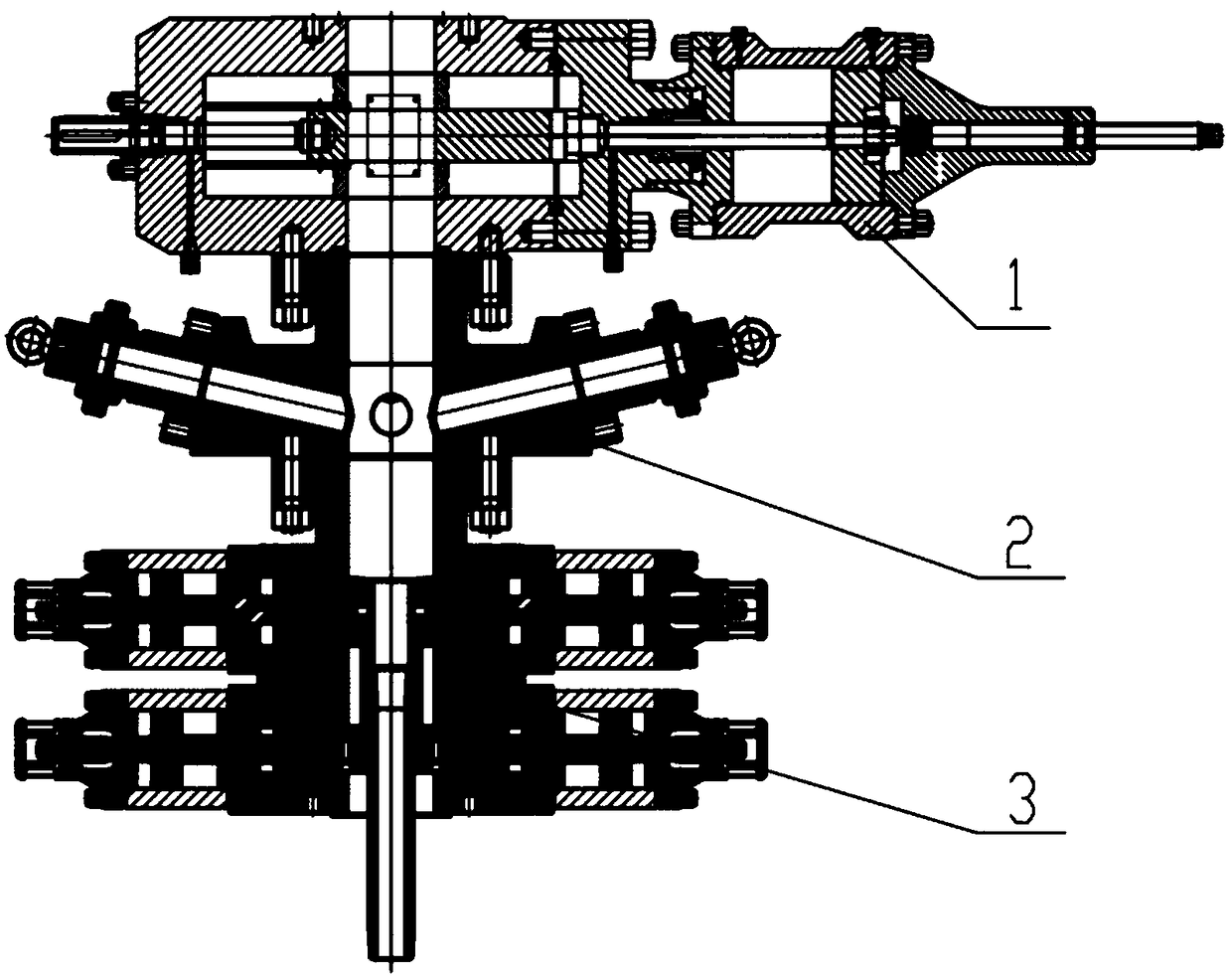

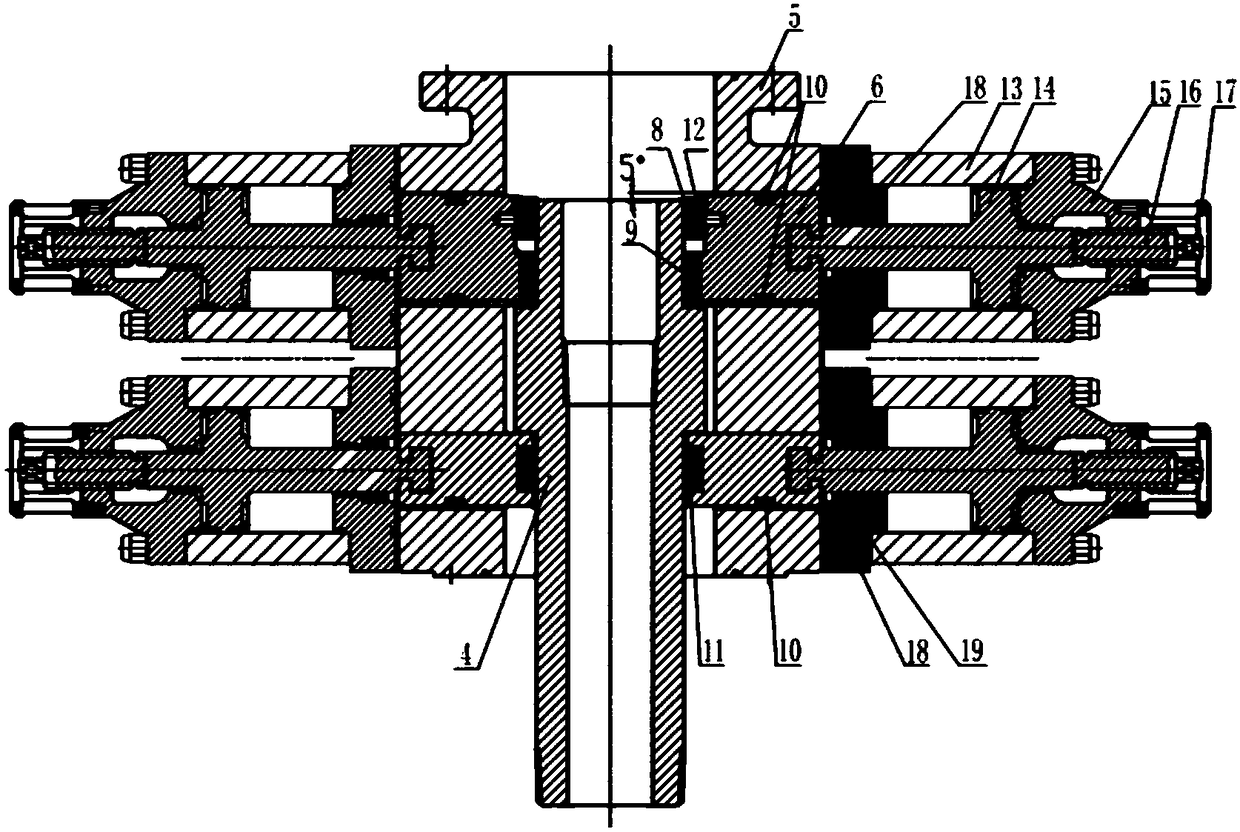

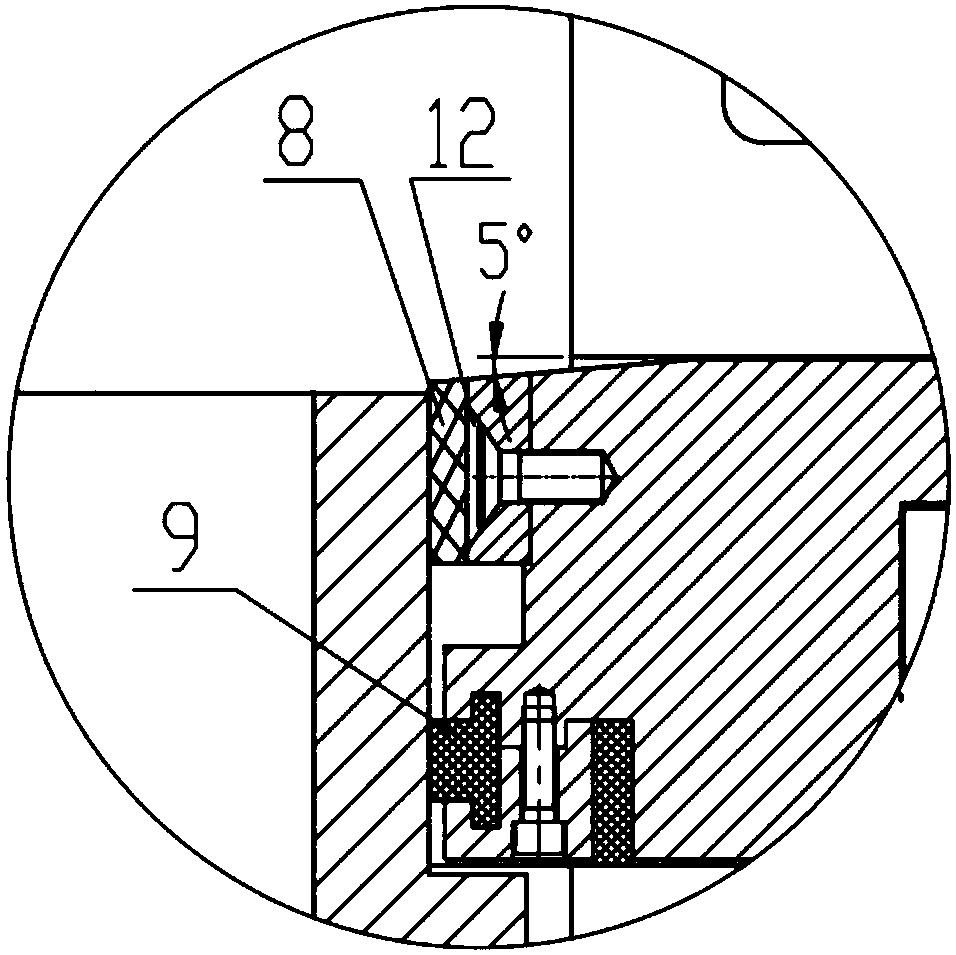

[0024] Such as Figure 1-4 As shown, it is an energy-saving combined pressure fracturing wellhead device of the present invention, which includes a hydraulic plate valve 1, a fracturing injection head 2, and a fracturing controller 3 connected in sequence. The fracturing controller 3 includes symmetrically arranged double gates Plate assembly, a channel through which the oil supply pipe hanger 4 passes is formed between the double ram assembly, the double ram assembly includes a half-sealed shell 5, and an upper ram 6 is arranged inside the half-sealed shell 5 and a The lower gate 7 below the plate 6, the end of the upper gate 6 is provided with slips 8 and the first sealing member arranged under the slips 8, the second seal is provided on the lower gate, and the upper gate 6 and the lower flashboard 7 can offset against the tubing hanger 4 under the promotion of the oil cylinder assembly.

[0025] The first seal includes a plane seal 9 and a top seal 10, the plane seal 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com