Construction method of special-shaped partition wall method in large-section tunnel with small net distance

A construction method and large-section technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as poor grades of surrounding rocks, and achieve the effects of ensuring safety, easy technology mastery, and easy organization and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

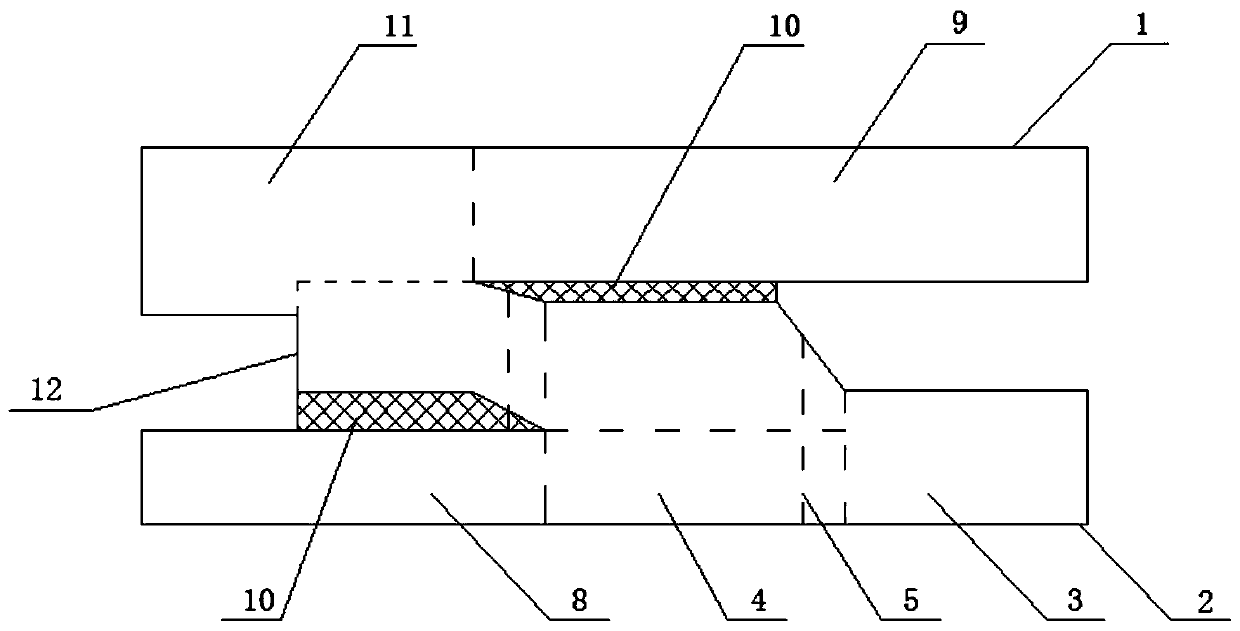

[0036] According to an embodiment of the present invention, the two-step method includes: excavating the upper step and reserving core soil; and excavating the lower step according to a predetermined footage. Preferably, the distance between the lower step and the upper step is within a predetermined range, which is enough to meet the excavation work space of the upper step, and the left and right spacing of the lower step and the excavation footage should be strictly controlled, and the footage should not exceed 3 steel supports at a time, so as to Ensure the safety of construction.

[0037] According to the technical solution of the present invention, step: 3) Simultaneously excavate the third section 8 of the second tunnel and the first section 9 of the first tunnel according to the first predetermined height, realizing the synchronous operation of the face of the small clear distance tunnel, Improve the construction efficiency and ensure the construction period.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com