Free section tunneling equipment

A section and equipment technology, applied in the field of free section tunneling equipment, can solve the problems of reduced rock breaking efficiency, increased frequency of tool change, increased probability of abnormal tool wear, etc., and achieve the effect of improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

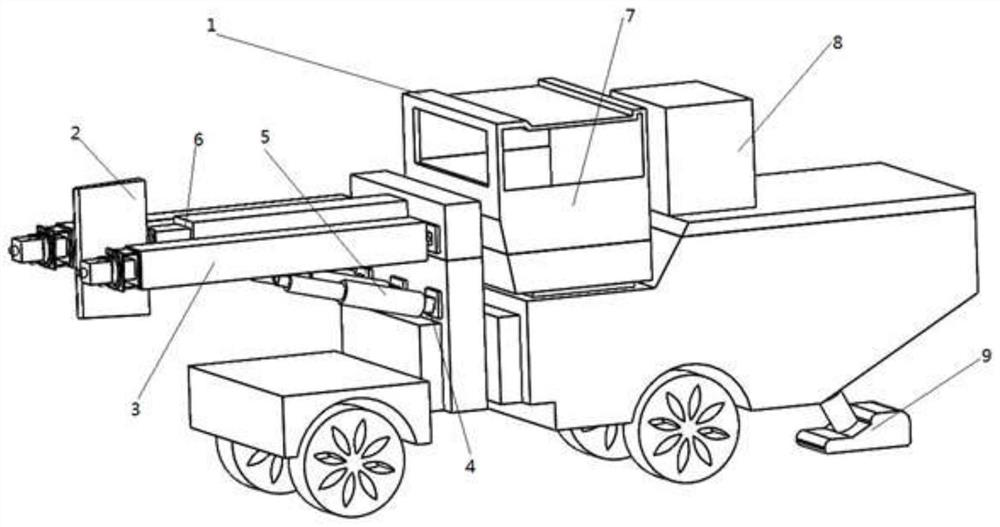

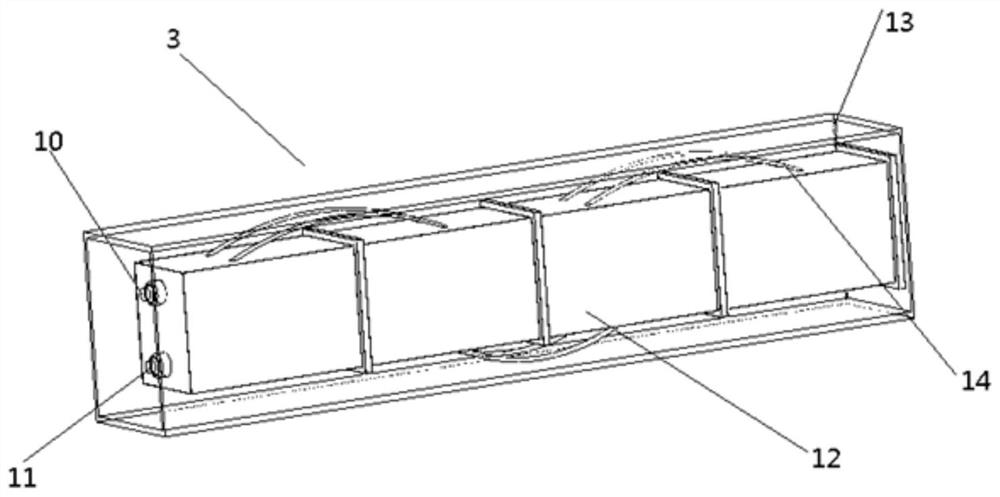

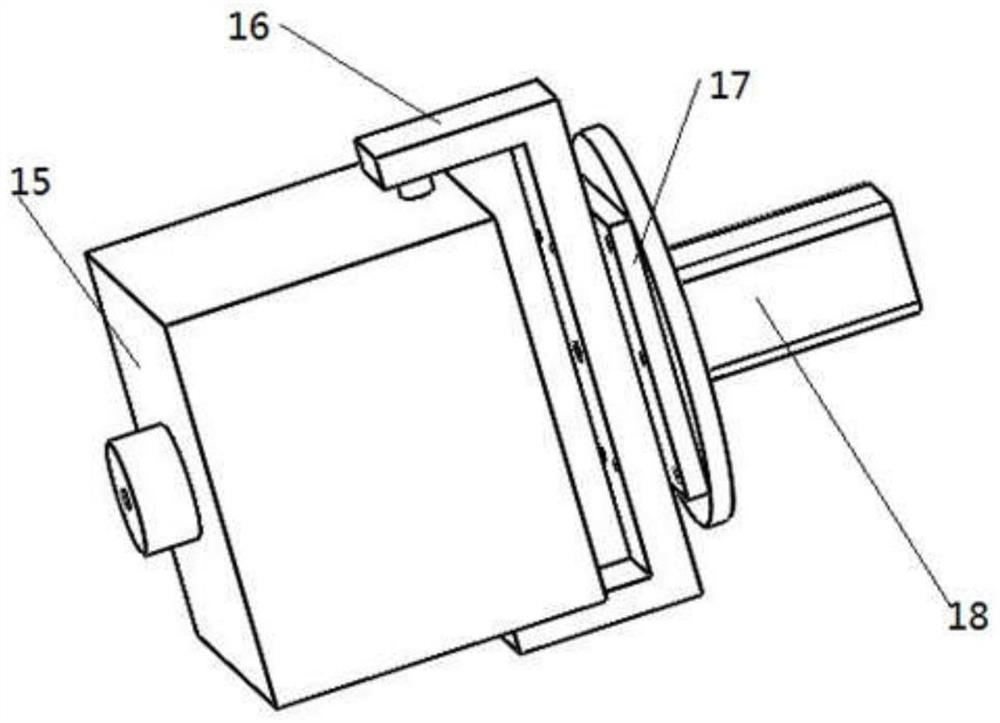

[0023] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a free-section excavation equipment, which includes a complete machine travel assembly 1 , a plurality of laser generating assemblies 3 and a wedge-shaped extrusion assembly 2 . The whole machine walking assembly 1 can travel along the direction of tunnel excavation; the laser generating assembly 3 is arranged on the whole machine walking assembly 1, and a plurality of laser generating assemblies 3 are configured to emit lasers that cut the face of the tunnel along a preset trajectory, so as to Make the tunnel surface form a concave-convex rock mass with a cut to be squeezed; the wedge-shaped extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com