Tunnel Excavation Method Based on Silent Breaker

A silent crushing agent, tunnel technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of complex construction, high cost, long construction period, etc., and achieve the effect of simple and convenient construction, fast expansion speed, and large force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

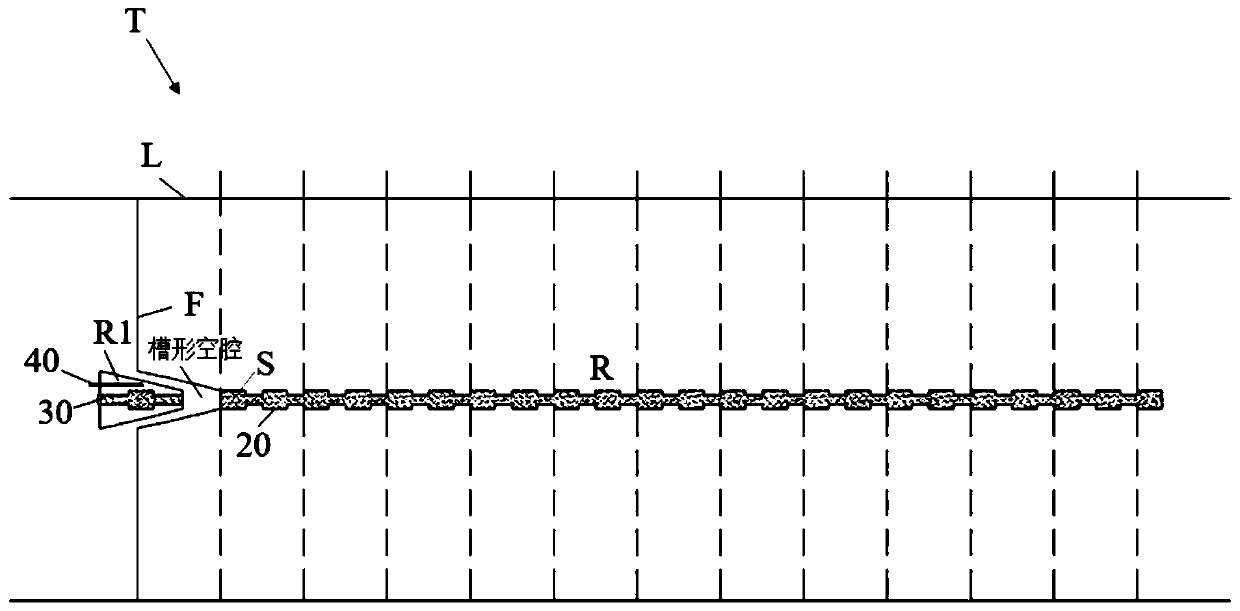

[0024] The specific implementation of the tunnel excavation method based on the silent breaker according to the present invention will be described in detail below in conjunction with the accompanying drawings.

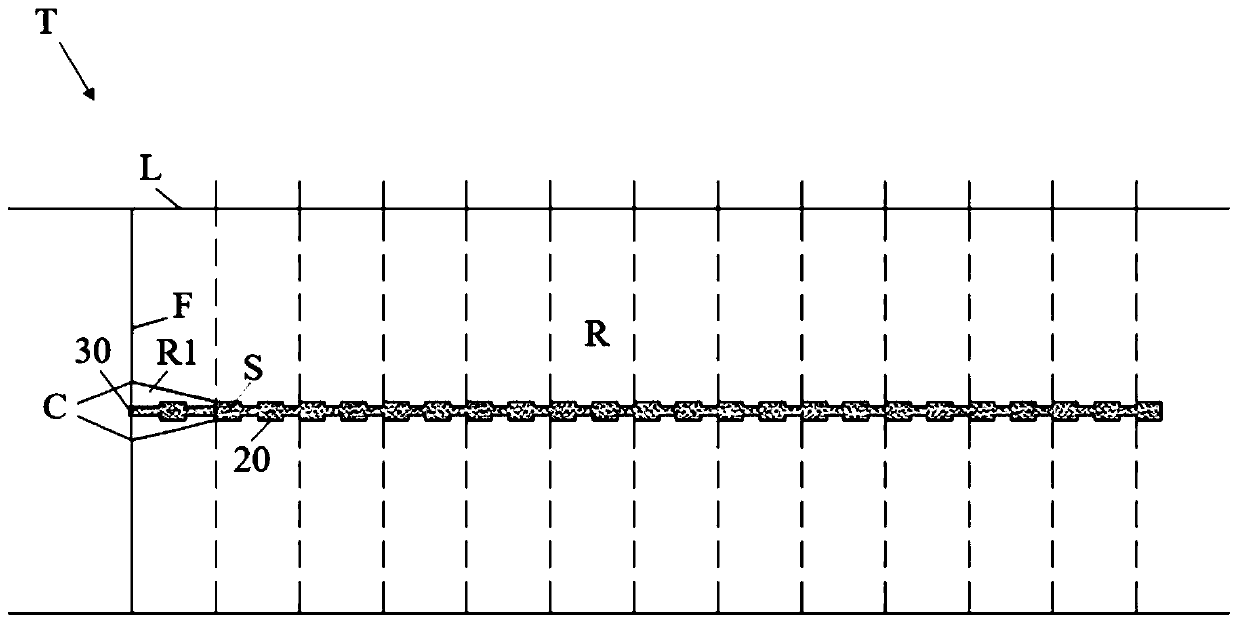

[0025] The axis of a tunnel project passes through a residential area. If the traditional blasting method is used to excavate the tunnel, excessive vibration and noise will be generated. In order to prevent excessive vibration and noise and reduce the impact on surrounding residents’ lives and buildings, the tunnel excavation method based on the silent breaking agent provided by this implementation is now used to excavate the tunnel, such as Figures 1 to 4 As shown, the specific steps are:

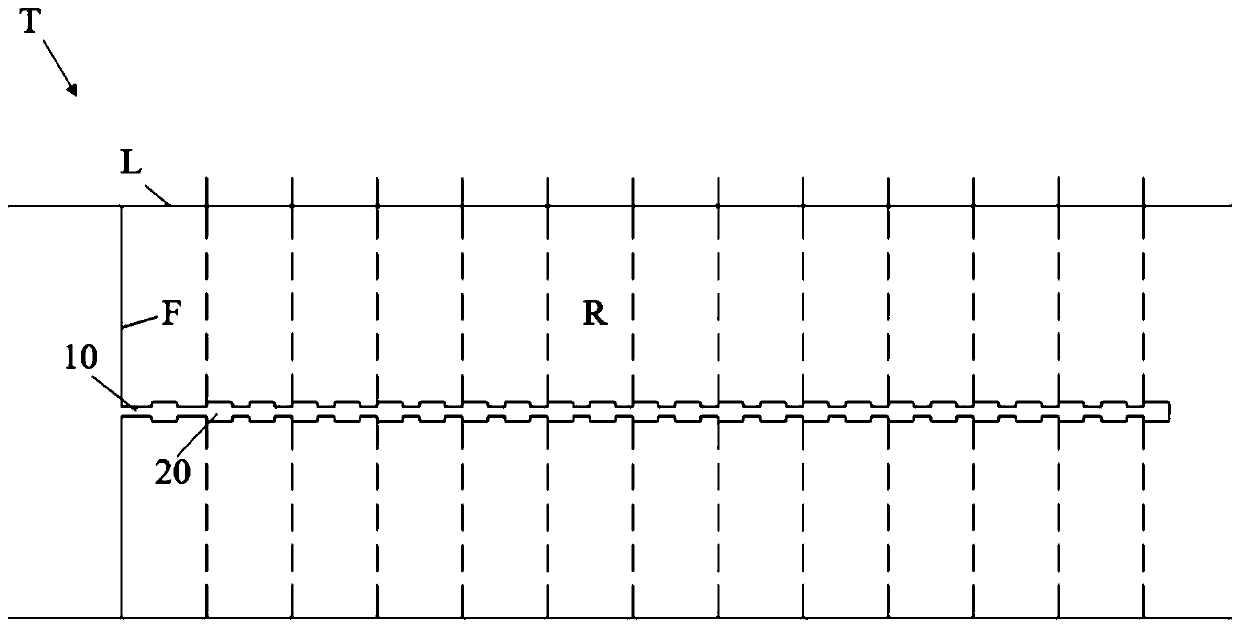

[0026] Step 1. If figure 1 As shown, according to the size of the section of the tunnel T, the cyclic footage L is determined to be 1.0m, and a hollow hole 10 with a diameter of 110mm and a depth of 12m is drilled at the designed cutting position, and the excavation is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com