Anti-loose nut assembly

A technology for anti-loosening nuts and assemblies, which is applied in the direction of nuts, threaded fasteners, screws, etc., which can solve the problems of increased relative displacement of thread contact surfaces, thread wear, and nut loosening, etc., to achieve increased friction and good application sex, lengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

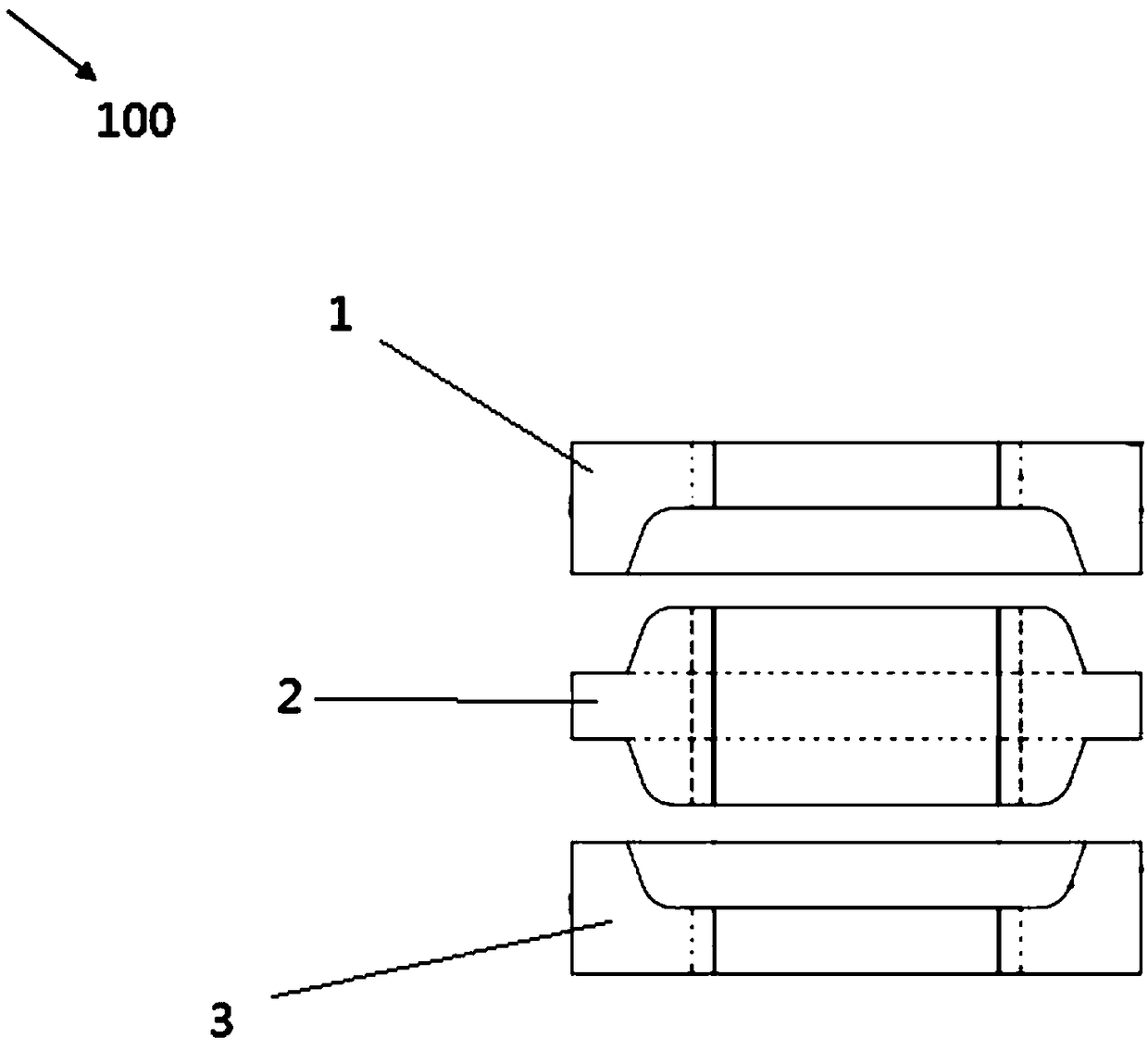

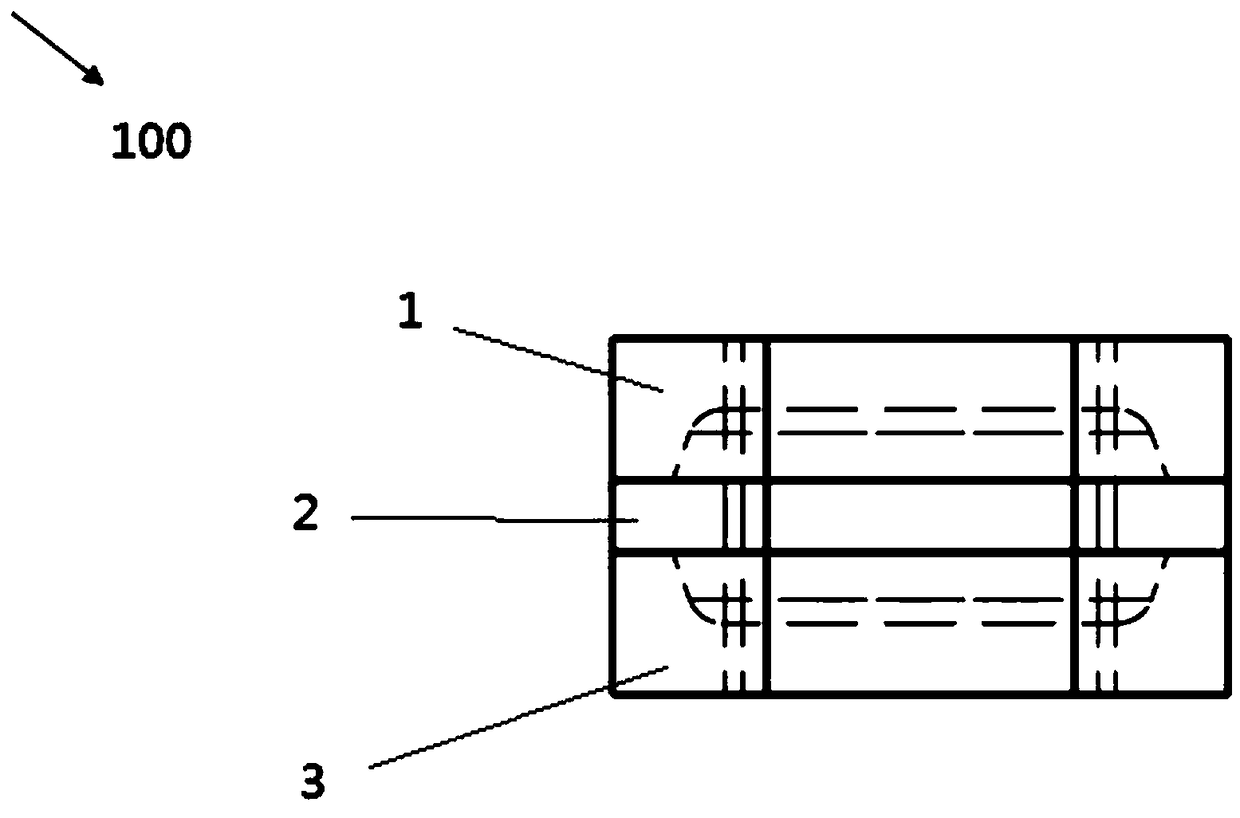

[0021] figure 1 It is a schematic exploded view of a locknut assembly in an embodiment of the present invention, figure 2 is an assembled front view of a locknut assembly in an embodiment of the present invention.

[0022] Such as figure 1 and figure 2 As shown, a locknut assembly 100 of the embodiment of the present invention is used to solve the problem of loosening of threaded connections, and has such features, including: a plurality of nuts, through which there are communication holes with internal threads; and bolts, Threads passing through the communicating hole and passing through the surface are engaged with internal threads, so as to securely connect a plurality of nuts.

[0023] The number of nuts is n≥3, and when n=3, the three nuts are the upper nut 1 , the middle nut 2 and the lower nut 3 connected by bolts.

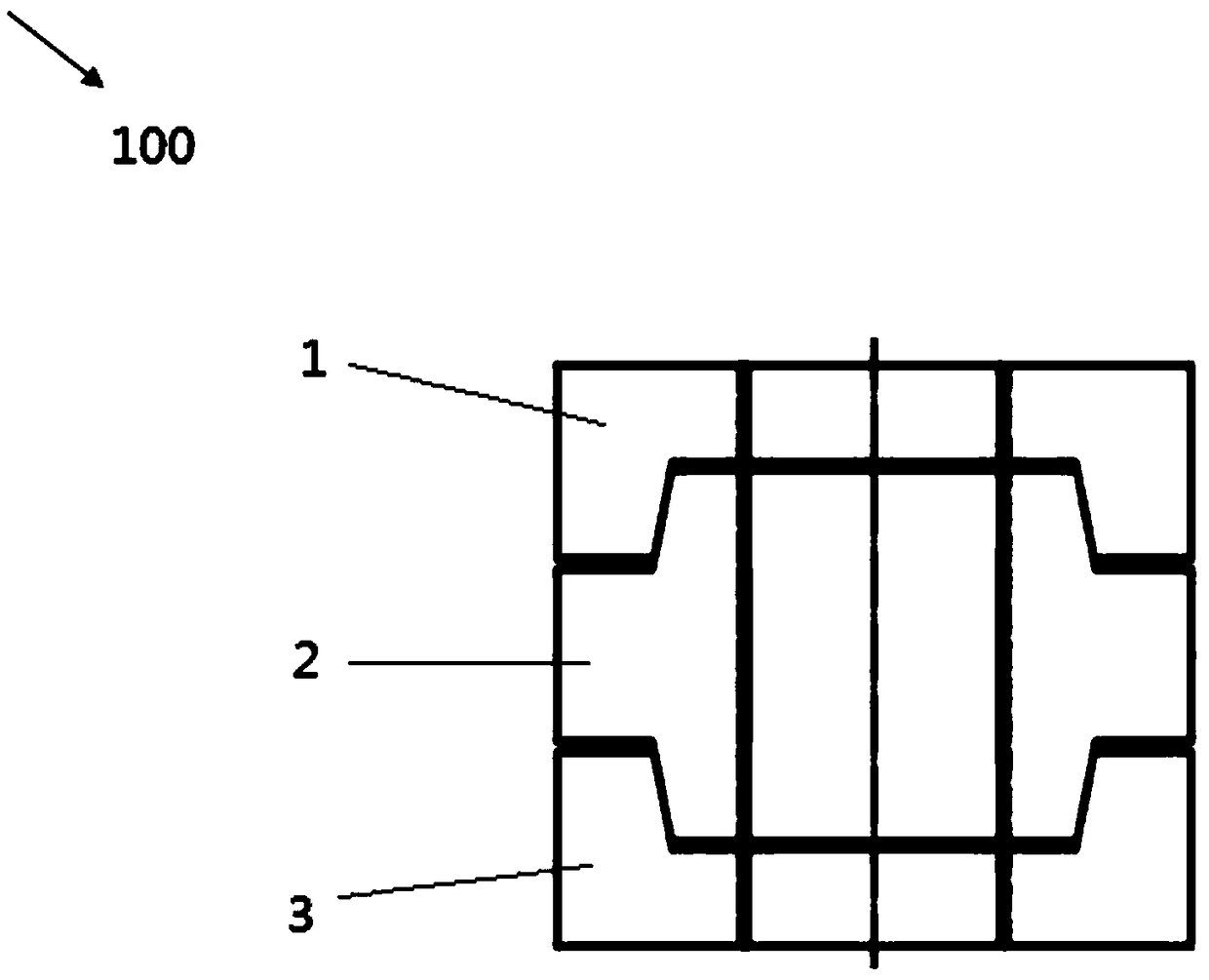

[0024] image 3 It is a structural schematic diagram of a locknut assembly using a middle nut with bosses on the top and bottom in an embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com