Crystal block drying device

A drying device and crystal technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of unfavorable crystal drying, reduced drying efficiency, and humid air, so as to avoid crystal drying, improve heat exchange efficiency, The effect of increasing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

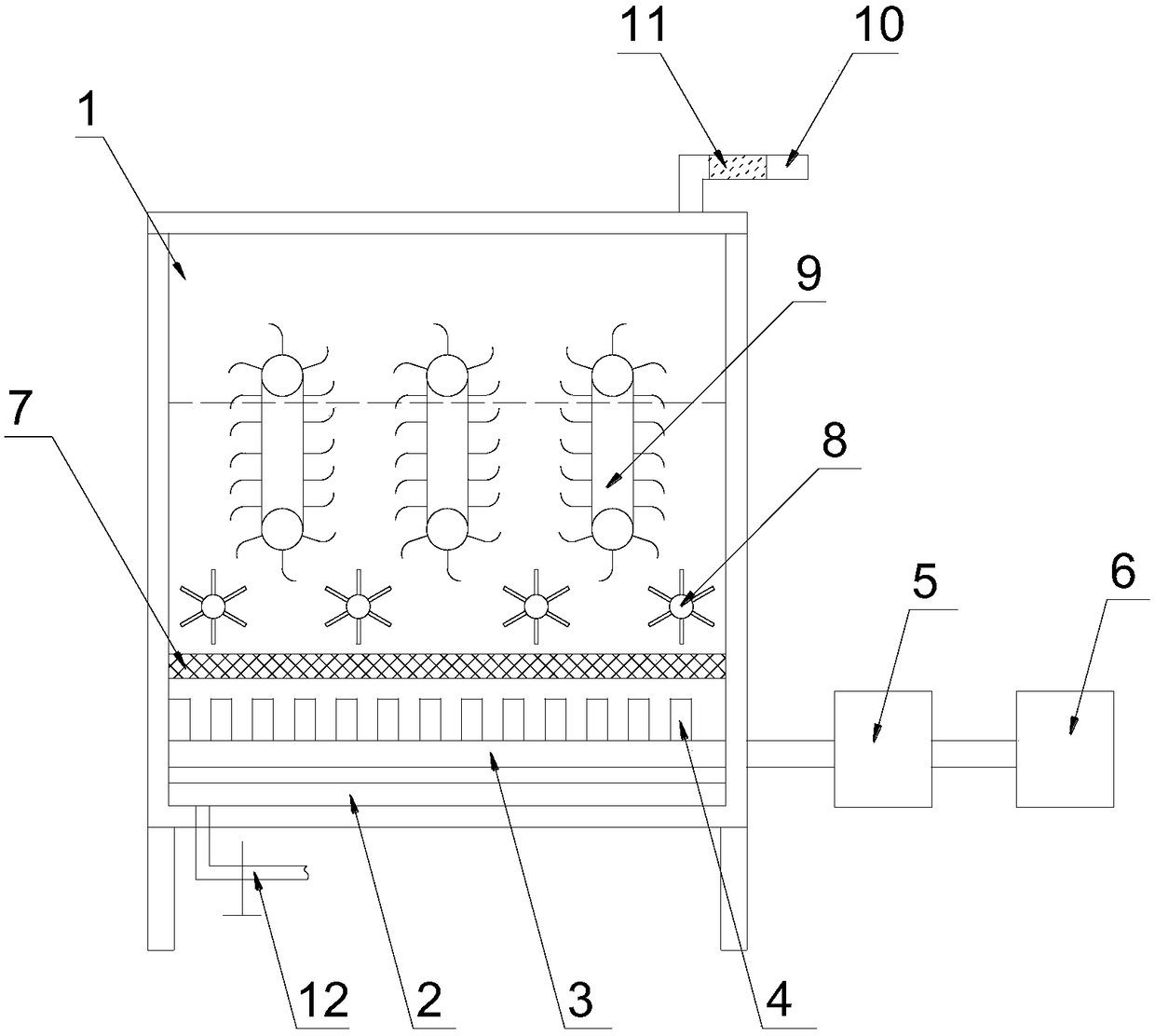

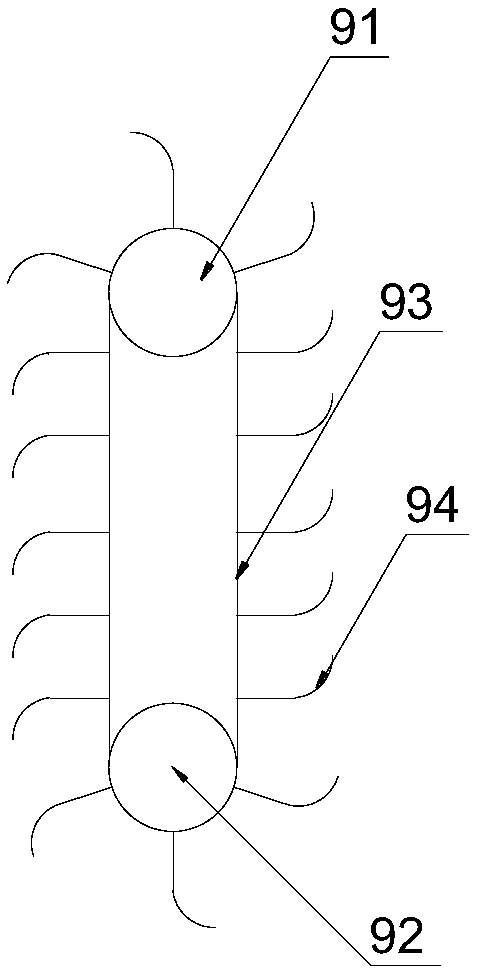

[0022] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a crystal block drying device proposed by the present invention; figure 2 It is a schematic diagram of part of the structure of the crystal block drying device proposed by the present invention.

[0023] refer to Figure 1-2 , a kind of crystal block drying device that the present invention proposes, comprises drying box 1, air filter 5, hot air blower 6 and exhaust pipe 10, and the sump 2 that is arranged on drying box 1 inside, air pipe 3, net Plate 7, stirring roller 8 and material turning device 9; wherein, material turning device 9 includes driving wheel 91, driven wheel 92, conveyor belt 93 and material turning plate 94;

[0024] The sump 2 is arranged at the bottom of the drying box 1, the bottom of the sump 2 is provided with a drainage pipe 12, and the drain pipe extends out of the drying box 1; The box 1 is connected to the air outlet of the air filter 5, and the air inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com