Test platform for combination properties of axial pulling and pressing, bending, torsion and vibration of composite material

A comprehensive performance testing, composite material technology, applied in the direction of analyzing materials, using stable bending force to test material strength, and using stable tension/pressure to test material strength, etc., can solve the problem of insufficient research on material performance and poor compatibility. , complex operation and other problems, to achieve the effect of rich test content, compact structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

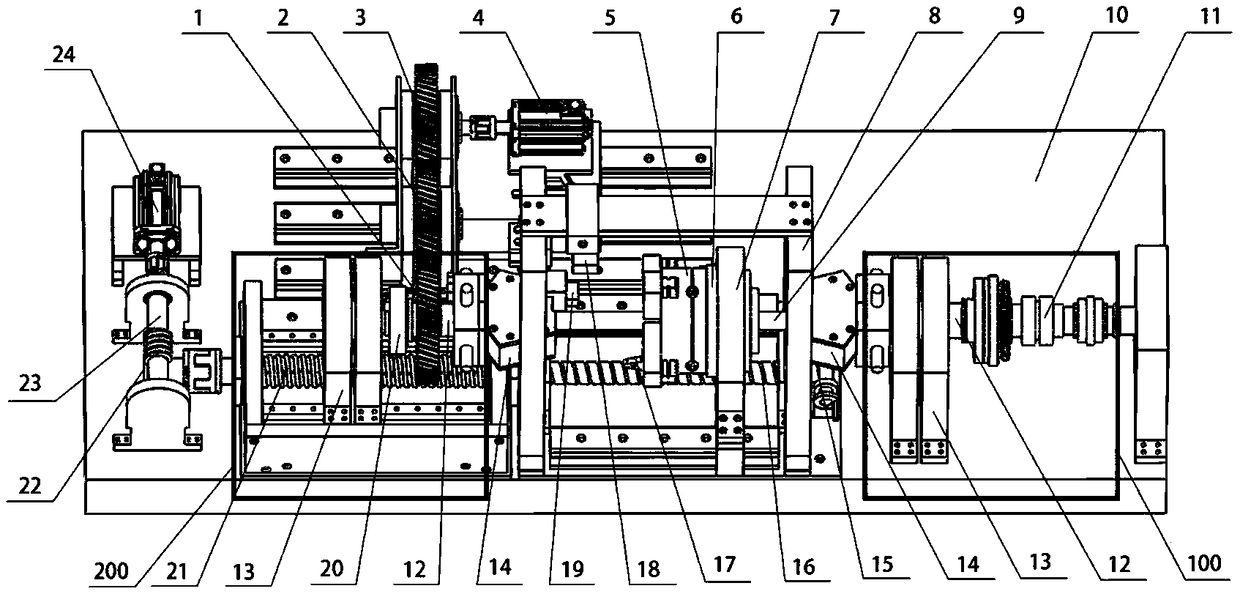

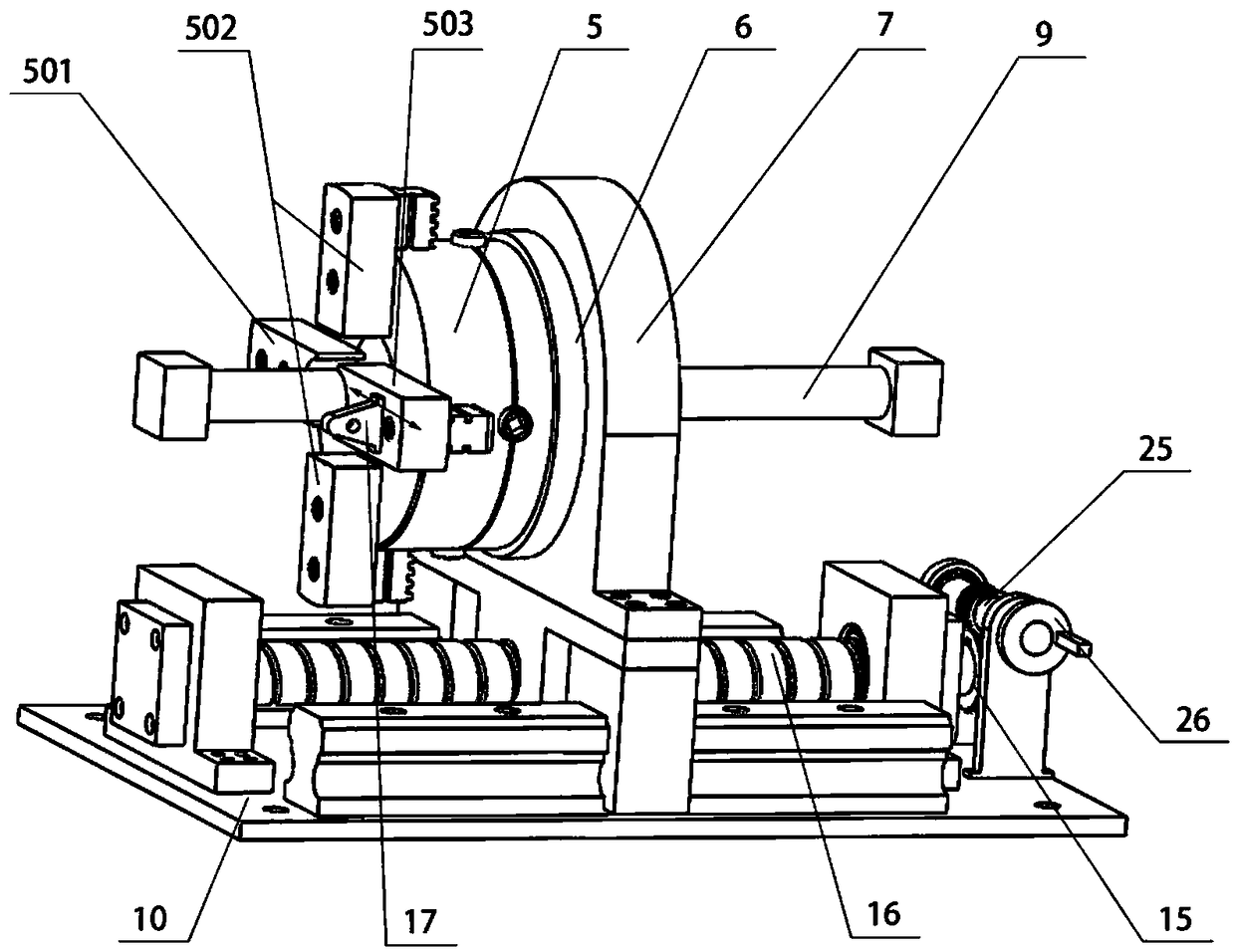

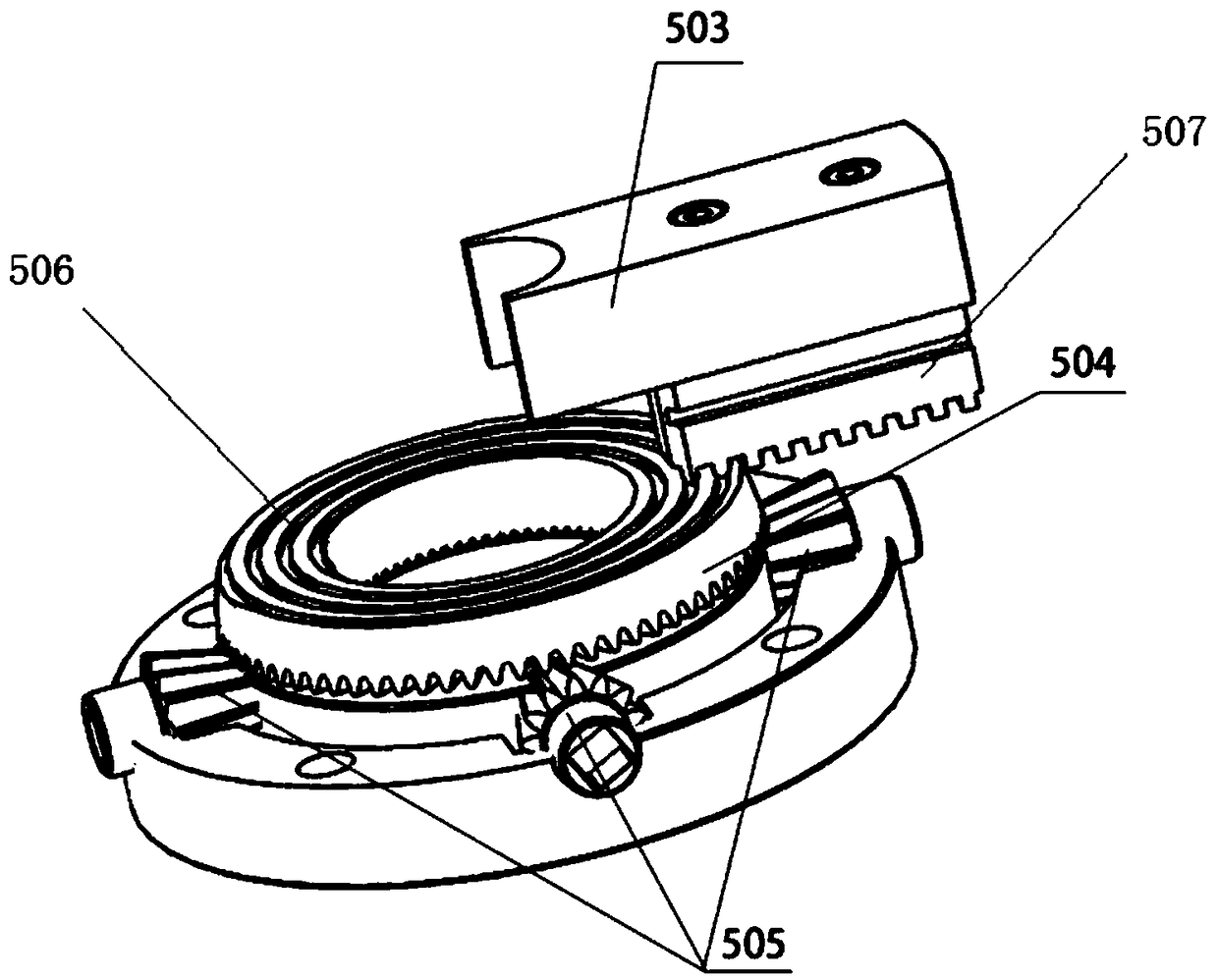

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the figure, a comprehensive performance test platform for composite material shaft tension, compression, bending, torsion, and vibration of the present invention includes a tension and compression unit, a bending unit, a torsion unit, and a vibration unit; a clamping device The fixed end 100 of the clamping device is fixed on the workbench 10; the movable end 200 of the clamping device is fixed on the torsion unit; the torsion unit is fixed to the tension and compression support seat 13 of the movable end 200; the tension and compression unit includes the tension and compression support seat 13, and the The lower part of the pull-press support seat 13 is provided with a threaded hole, and the threaded hole cooperates with the first lead screw 21, and the first lead screw 21 rotates coaxially with the worm wheel 22, and the worm wheel 22 meshes with the worm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com