Aging test method

An aging test and aging furnace technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inability to meet production requirements and low manual operation efficiency, and achieve the effect of purifying the environment and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The first embodiment provides an aging tester, which is used in the aging test of electronic products, so as to improve its degree of automation and work efficiency.

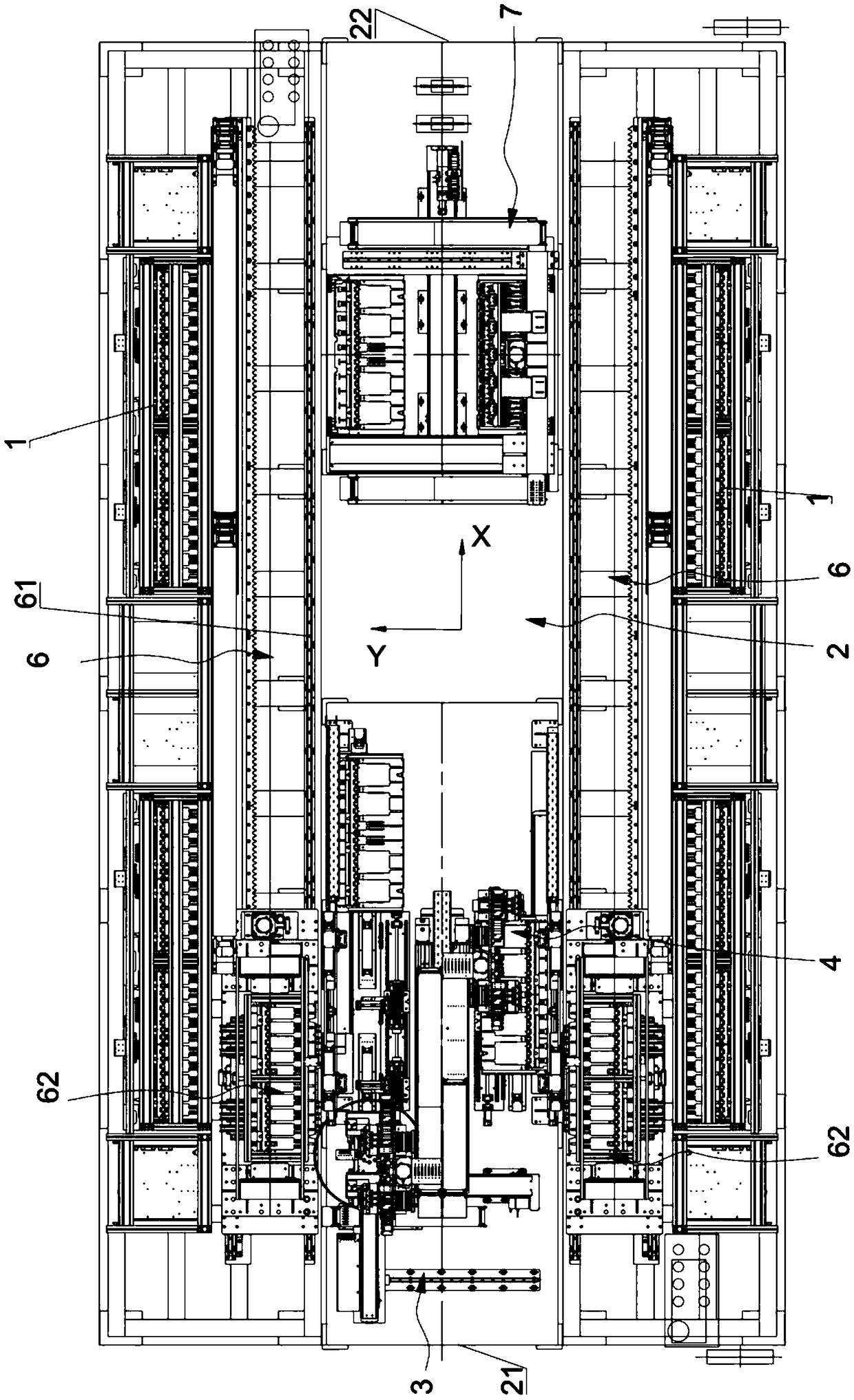

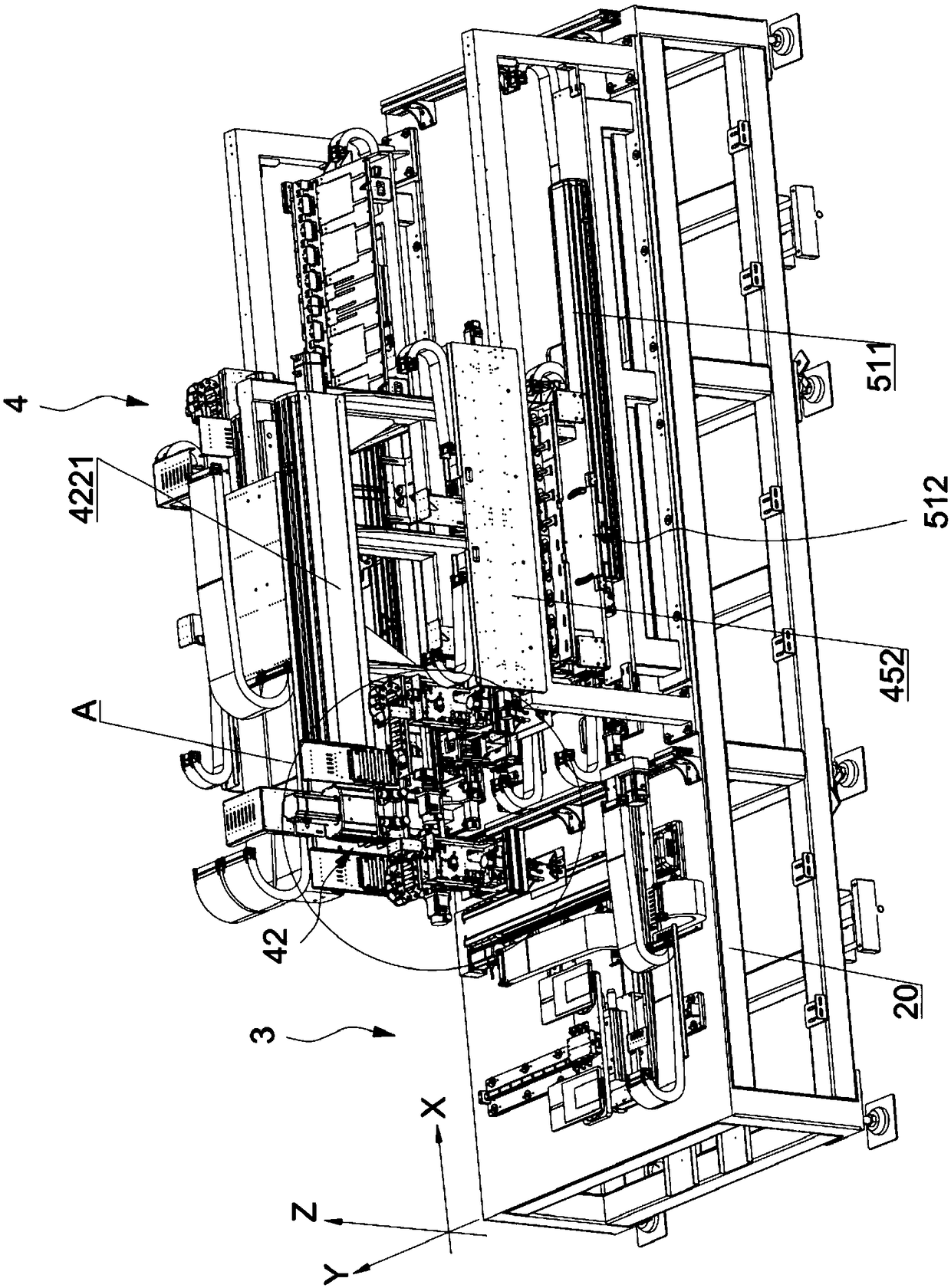

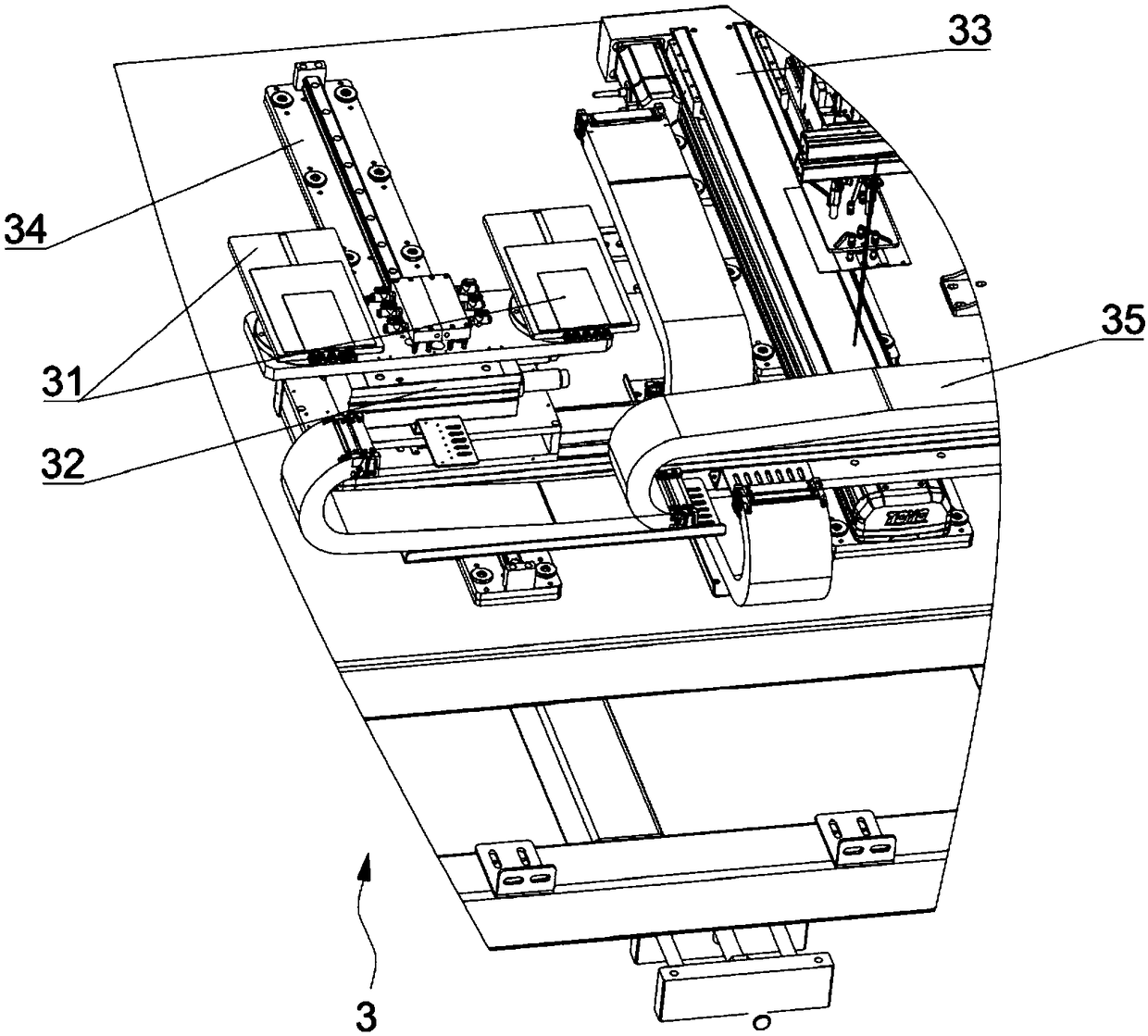

[0058] Such as figure 1 As shown, the aging testing machine provided in this embodiment includes an aging furnace body 1, a conveying channel 2 and a conveying device. The transport channel 2 is arranged on one side of the aging furnace body 1, and the transport channel 2 includes a channel inlet 21 and a channel outlet 22 respectively arranged at its two ends; The heads are combined to form the workpiece to be aged; the transport device is arranged in the transport channel 2, which is used to transport the panel from the channel entrance 21 to the alignment module 4, and transport the workpiece to be aged to the aging furnace body 1, and the aging The tested workpiece is carried out from the aging furnace body 1 , and the panel after the aging test is carried to the channel exit 22 .

[0059] In this e...

Embodiment 2

[0101] Embodiment 2 provides an aging testing method, which can be applied to the aging testing machine in Embodiment 1, but is not limited thereto, and can also be used in other aging testing equipment to improve panel aging efficiency.

[0102] The aging test method that present embodiment two provides comprises the following steps:

[0103] Step 1, providing an aging testing machine, wherein the aging testing machine includes an aging furnace body 1, a transport channel 2 arranged on one side of the aging furnace body 1, and a transport device arranged in the transport channel 2;

[0104] Step 2, loading the panel to be aged on the handling device, and combining the panel with the test indenter to form the workpiece to be aged; in this step, the positioning component can detect the position information of the panel on the carrier 10 , to determine whether the panel is at the preset position of the carrier 10, if the panel is at the preset position, the test indenter presses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com