Transformer and manufacturing method thereof

A manufacturing method and transformer technology, applied in the field of transformers, can solve the problems of insufficient isolation distance between primary coil and secondary coil, insufficient installation of primary coil and secondary coil, displacement of primary coil and secondary coil, etc., to achieve The effect of stable structure, maintaining consistency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

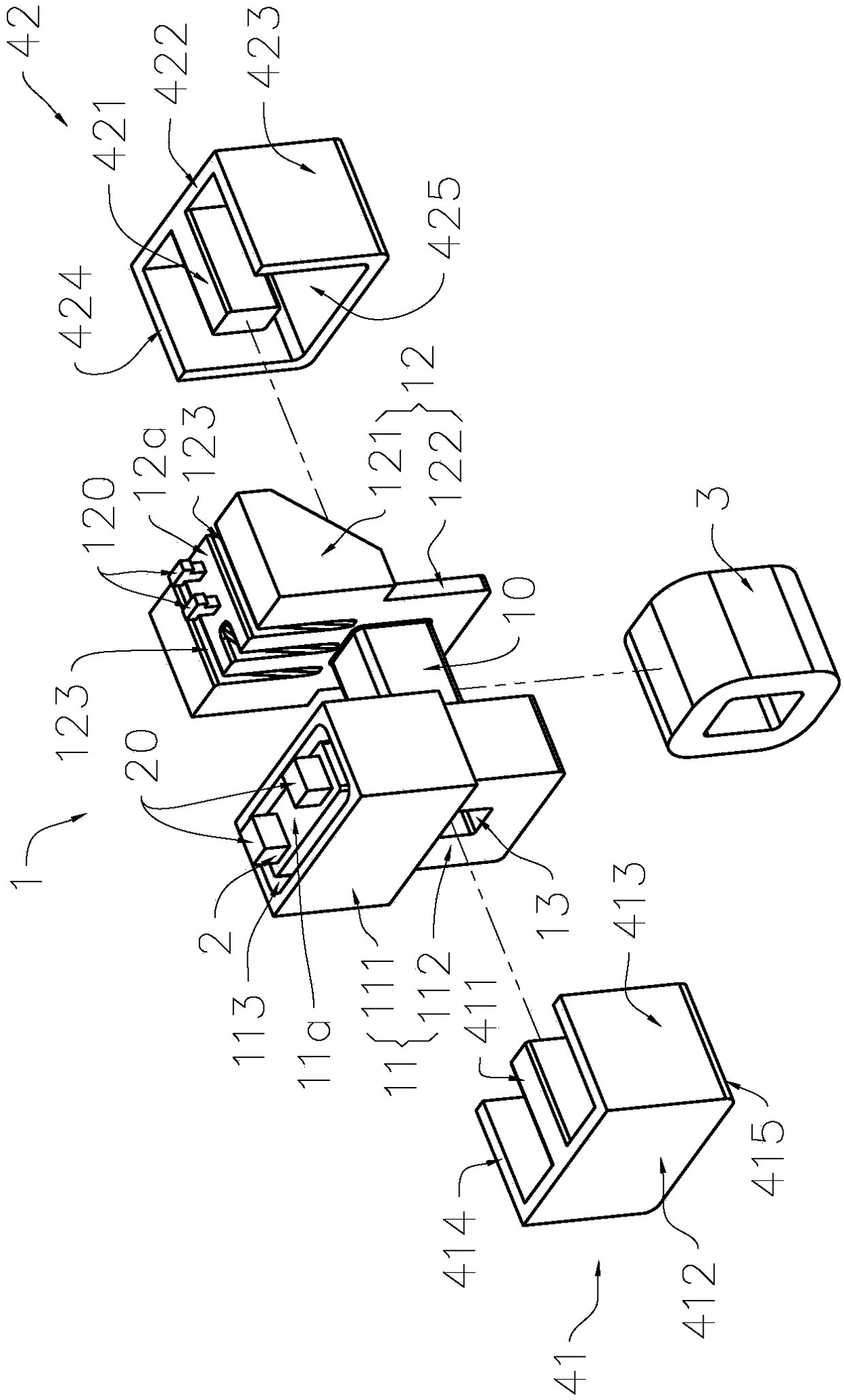

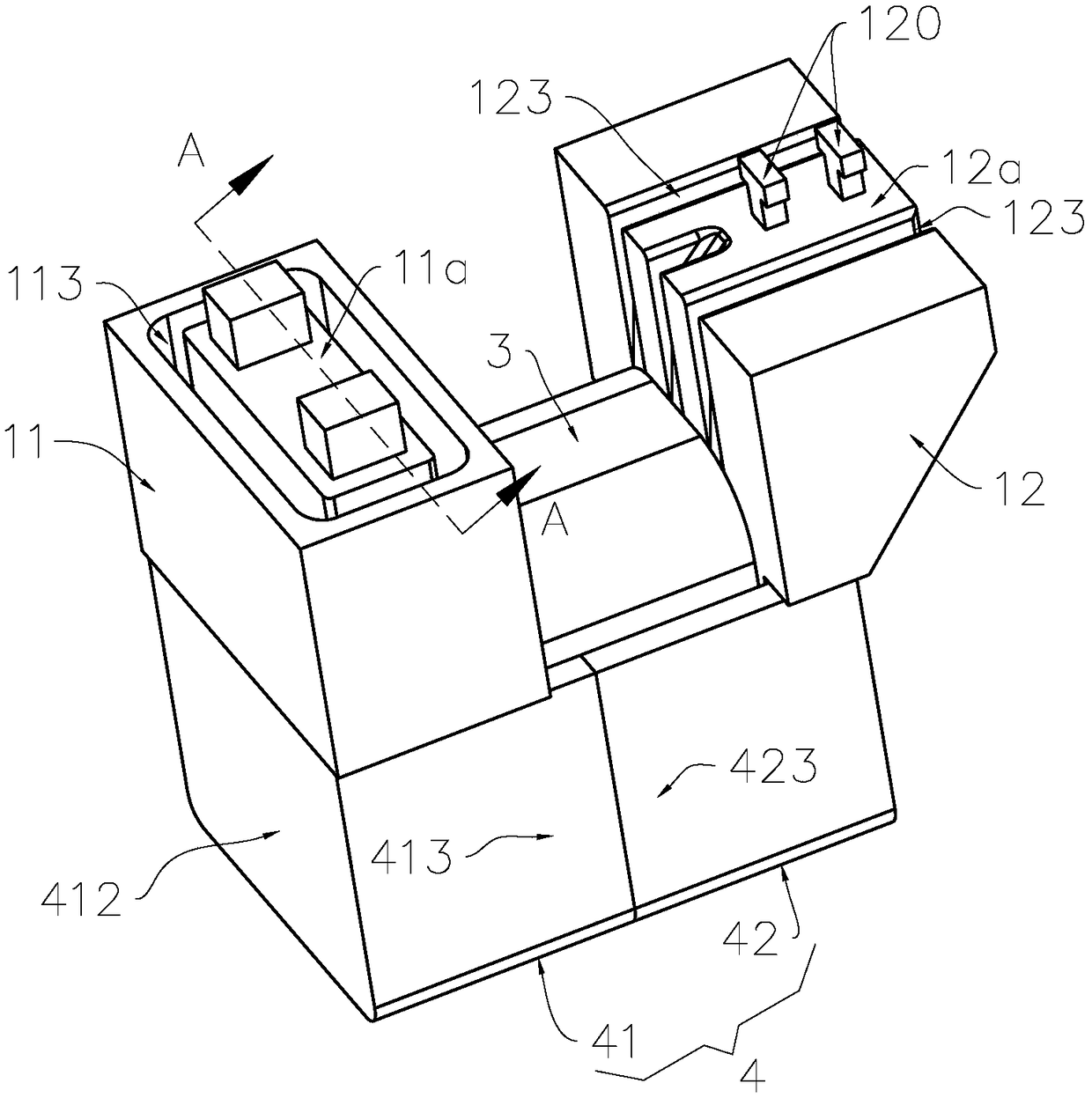

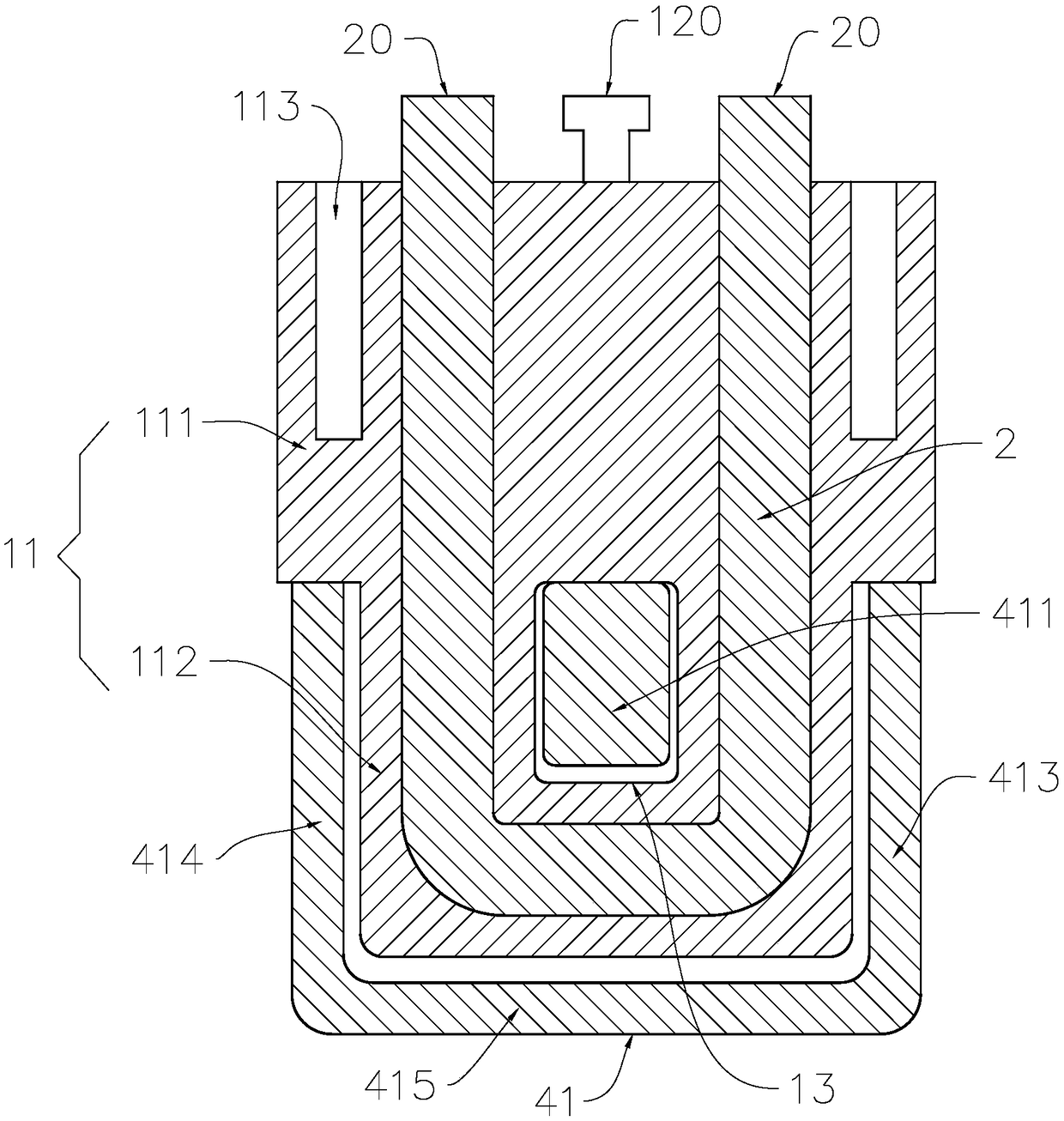

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. In order to better illustrate this embodiment, some appendices in the drawings are omitted, enlarged or reduced; for those skilled in the art, it is understandable that some known structures and their descriptions in the drawings may be omitted.

[0029] The transformer in this embodiment is mainly applied to the current transformer in the measurement circuit and protection circuit of automobiles and various electrical equipment, and converts a large current on the primary side into a small current on the secondary side. Because the conventional transformer winds both the primary coil and the secondary coil on the skeleton, the process is complicated, and the distance between the primary coil and the secondary coil cannot reach the safe isolation distance. In the transformer of this embodiment, the primary coil is placed in the mold while the mold is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com