A winding automatic shaping device

A shaping device and fully automatic technology, which is applied in the field of transformer manufacturing, can solve the problems of re-turning of windings, direct placement of windings, difficulties, etc., and achieve the effects of reducing labor intensity, convenient transportation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

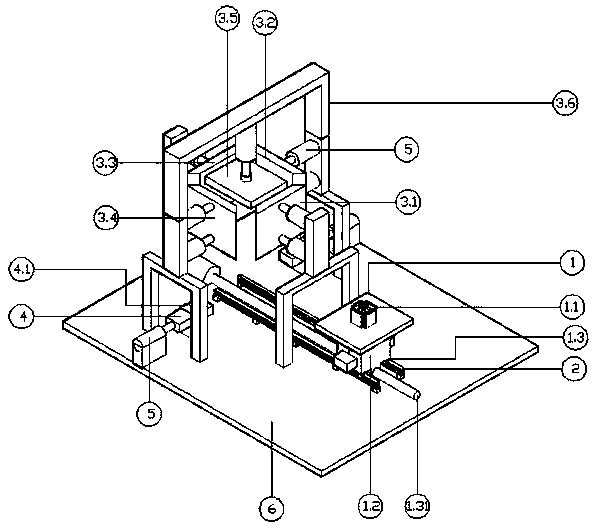

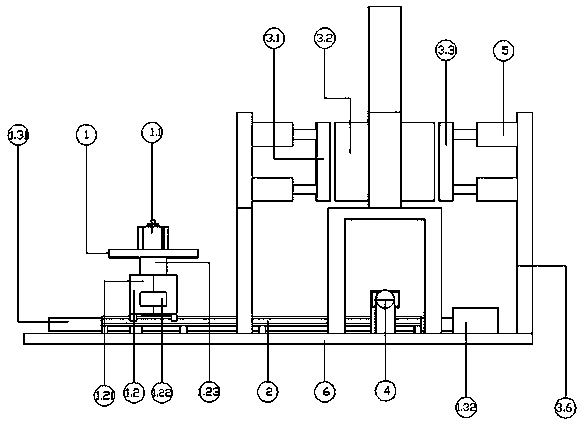

[0019] Embodiment one; figure 1 , 2 , 3, 4, and 5, a fully automatic winding shaping device, including a pressure bearing plate 1, a slide rail 2, and a shaping device 3, wherein the pressure bearing plate 1 is a rectangular plate, and the top of the pressure bearing plate 1 is fixed with a positioning The column 1.1, the positioning column 1.1 includes the sliding plate 1.11 and the adjusting screw 1.13 around, and the upper and lower ends of the inner wall of each sliding plate 1.11 are hinged with linkage rods 1.12, and every four linkage rods 1.12 are located at the upper end of the sliding plate 1.11 The other end is hinged on the same sleeve, and the other end of every four linkage rods 1.12 located at the lower end of the sliding plate 1.11 is also hinged on the same sleeve. The same adjustment screw 1.13 is inserted into the two sleeves and the adjustment screw 1.13 The two sleeves are threaded, and the bottom of the adjustment screw 1.13 is rotatably fixed at the cen...

Embodiment 2

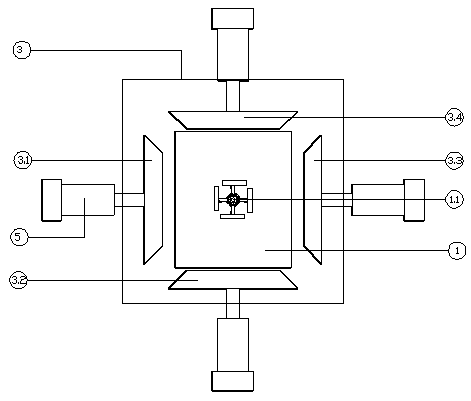

[0020] Embodiment two; Image 6 As shown, the first shaping plate 3.1, the second shaping plate 3.2, the third shaping plate 3.3, and the fourth shaping plate 3.4 all include the middle vertical plate 3.7 and the splicing plate 3.8, wherein the vertical plate 3.7 is located in the middle and the back side of the vertical plate 3.7 Cylinder 5 is fixed, and is formed by splicing plate 3.8 on both sides of vertical plate 3.7, wherein between splicing plate 3.8 and vertical plate 3.7 is fastened by threaded tie rod 3.9; Horizontal hole is drilled on each vertical plate 3.7, A horizontal hole is also drilled on each splicing plate 3.8, and the threaded tie rod 3.9 is inserted into the hole of the splicing plate 3.8 and the vertical plate 3.7, and then tightened by the threaded pull rod 3.9, so that the splicing plate 3.8 and the vertical plate 3.7 are fixed together In this way, the widths of the first shaping plate 3.1, the second shaping plate 3.2, the third shaping plate 3.3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com