A battery cell of a secondary battery and a preparation method of the battery cell

A secondary battery and cell technology, which is applied in the manufacture of secondary batteries, battery electrodes, and electrolyte batteries, can solve the problems of high power consumption and high cost, achieve guaranteed performance, good industrialization potential, and slow down charging performance. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

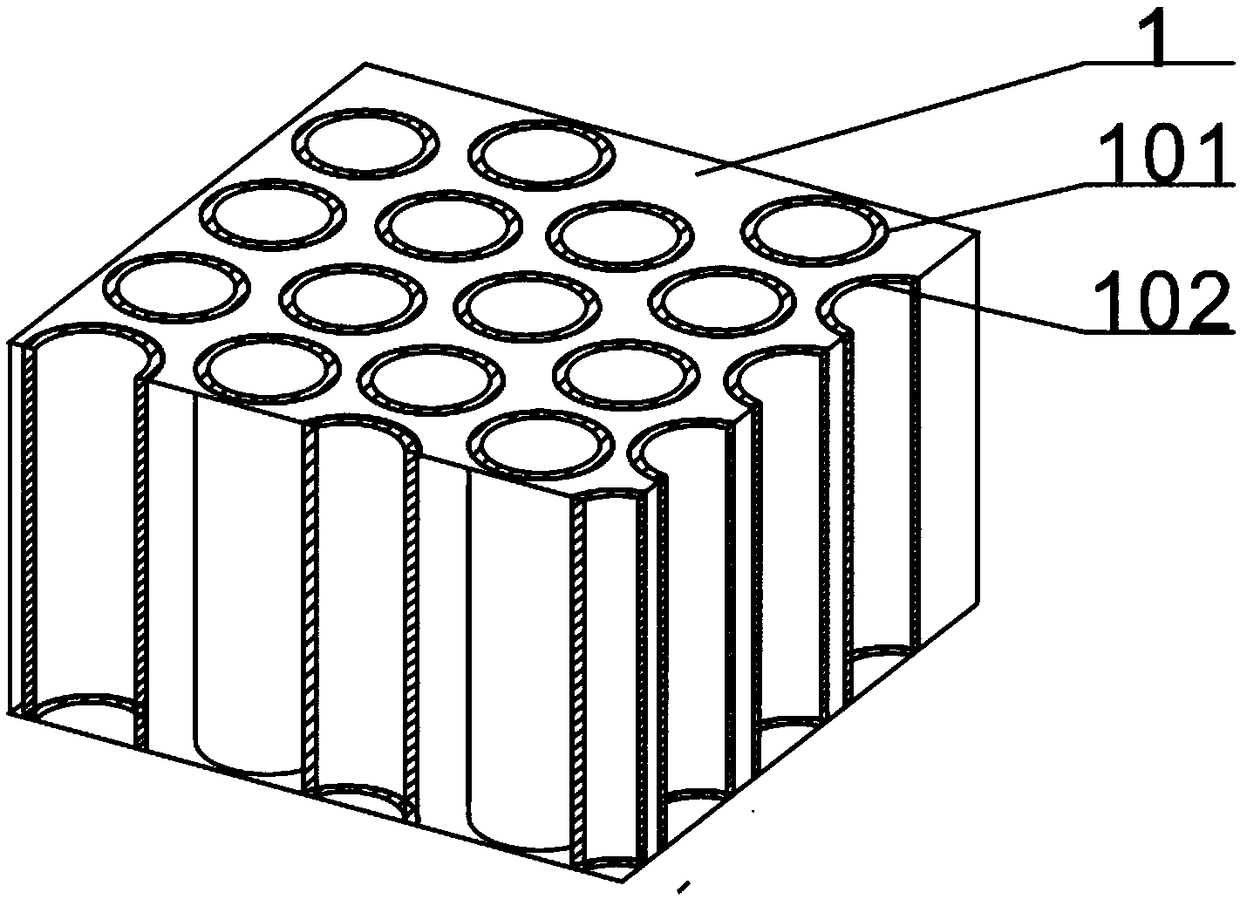

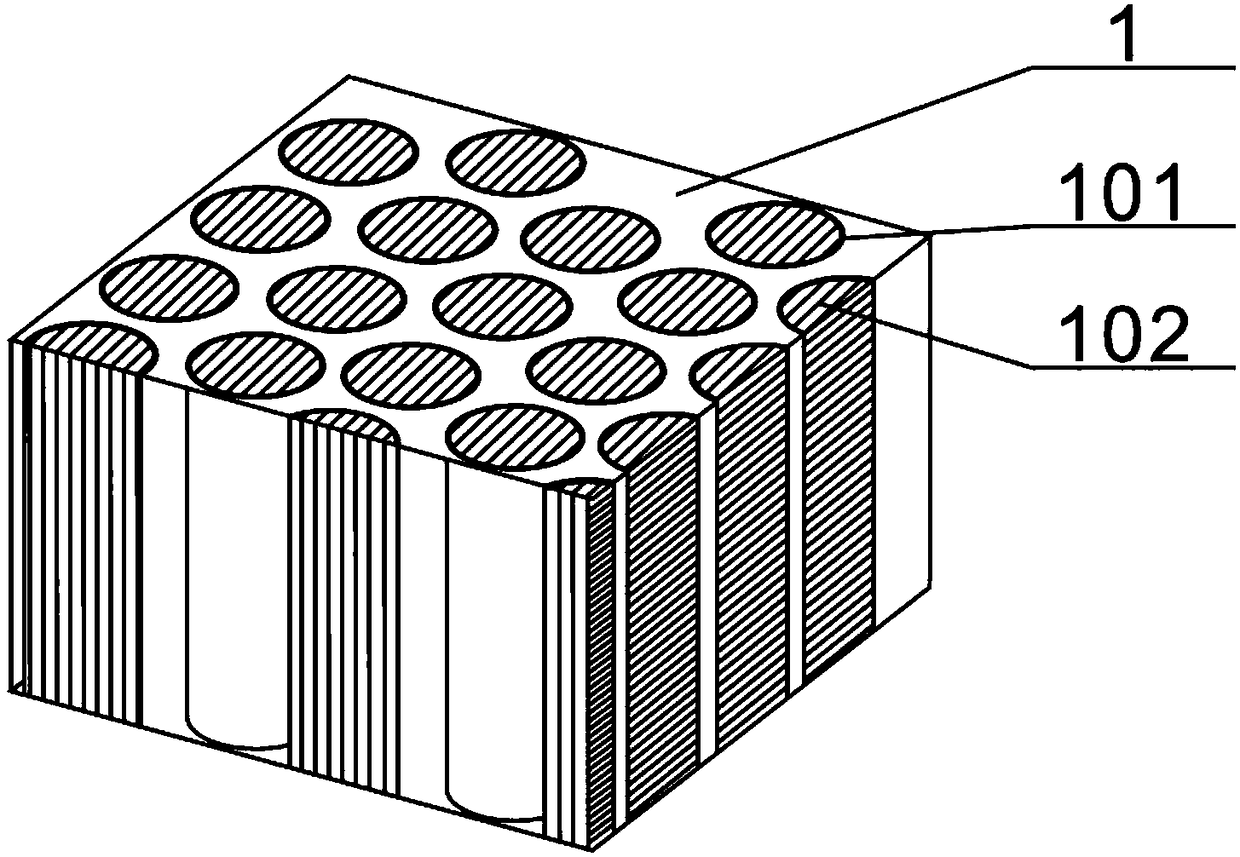

[0031] A battery cell of a secondary battery, comprising a positive electrode sheet, a negative electrode sheet, a separator and an electrolyte, the separator is arranged between the positive electrode sheet and the negative electrode sheet, and both the positive electrode sheet and the negative electrode sheet Including a porous current collector 1, each of which is provided with an NTC material body 102;

[0032] Each hole 101 of the porous current collector 1 is provided with the NTC material body 102, and the NTC material body 102 is seamlessly fixedly connected with the inner wall of the hole 101 of the porous current collector 1; the present invention combines the NTC material body 102 is pressed in the pores 101 of the porous positive and negative current collectors, which not only ensures low-temperature heating characteristics, but also does not occupy the space of the secondary battery itself, and does not cause battery performance degradation due to the addition of N...

Embodiment 2

[0036] Such as figure 1 : a battery core of a secondary battery, comprising a positive electrode sheet, a negative electrode sheet, a separator and an electrolyte, the separator is arranged between the positive electrode sheet and the negative electrode sheet, the positive electrode sheet and the negative electrode sheet Both include a porous current collector 1, and each of the porous current collectors 1 is provided with an NTC material body 102;

[0037] Each hole 101 of the porous current collector 1 is provided with the NTC material body 102, and the NTC material body 102 is seamlessly fixedly connected with the inner wall of the hole 101 of the porous current collector 1; the present invention combines the NTC material body 102 is pressed in the pores 101 of the porous positive and negative current collectors, which not only ensures low-temperature heating characteristics, but also does not occupy the space of the secondary battery itself, and does not cause battery perf...

Embodiment 3

[0050] Such as figure 1 Shown: a battery cell of a secondary battery, comprising a positive electrode sheet, a negative electrode sheet, a separator and an electrolyte, the separator is arranged between the positive electrode sheet and the negative electrode sheet, the positive electrode sheet and the negative electrode sheet The negative plates all include a porous current collector 1, and each of the porous current collectors 1 is provided with an NTC material body 102;

[0051]Each hole 101 of the porous current collector 1 is provided with the NTC material body 102, and the NTC material body 102 is seamlessly fixedly connected with the inner wall of the hole 101 of the porous current collector 1; the present invention combines the NTC material body 102 is pressed in the pores 101 of the porous positive and negative current collectors, which not only ensures low-temperature heating characteristics, but also does not occupy the space of the secondary battery itself, and does...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com