Method for promoting removal of COS and CS2 in natural gas

A natural gas and removal technology, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve the problems of increasing the cost of purification and treatment, limiting the processing capacity of the absorption device, etc., to increase the load, improve the degree of removal, and reduce the total effect of sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

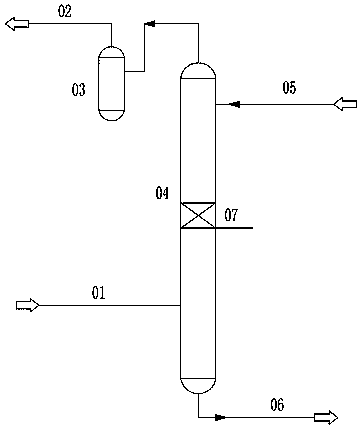

Image

Examples

Embodiment 1

[0018] The test raw material gas and conditions are the same as those of Comparative Example 1, but a section of 150mm high COS and CS is added to the middle and lower part of the absorption tower 2 Hydrolysis catalyst. The test results are shown in Table 1.

Embodiment 2

[0020] The test pressure is 2.5MPa, and the other test raw materials and conditions are the same as in Comparative Example 1, but a section of 150mm high COS and CS is added to the middle and lower part of the absorption tower 2 Hydrolysis catalyst. The test results are shown in Table 1.

Embodiment 3

[0022] The pressure of the natural gas used in the test is 2.5MPa, it enters the test device at room temperature, and the volume fraction of the main component of the natural gas is H 2 S 2.0%, CO 2 5.0%, COS 300ppmv, CS 2 100ppmv and the rest are nitrogen, but a section of 300mm high COS and CS is added to the middle and lower part of the absorption tower 2 Hydrolysis catalyst. The test results are shown in Table 1.

[0023] The test result of table 1 comparative example and embodiment

[0024] project

gas-liquid ratio

COS removal rate

CS 2 Removal rate

comparative example

200

43.7%.

31.3%

Implementation column 1

200

83.8%

75.6%

Implementation column 2

230

79.2%

73.0%

Implementation column 3

200

80.5%

73.4%

[0025]The gas-liquid ratio in Table 1 is the ratio of the gas flow to the absorption liquid flow, which can be used to measure the processing load. For the built test devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com