Punching machine for bolt machining

A stamping machine and bolt technology, applied in the field of mechanical processing equipment, can solve the problems of small application range, inconvenient die replacement, single bolt type, etc., and achieve the effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

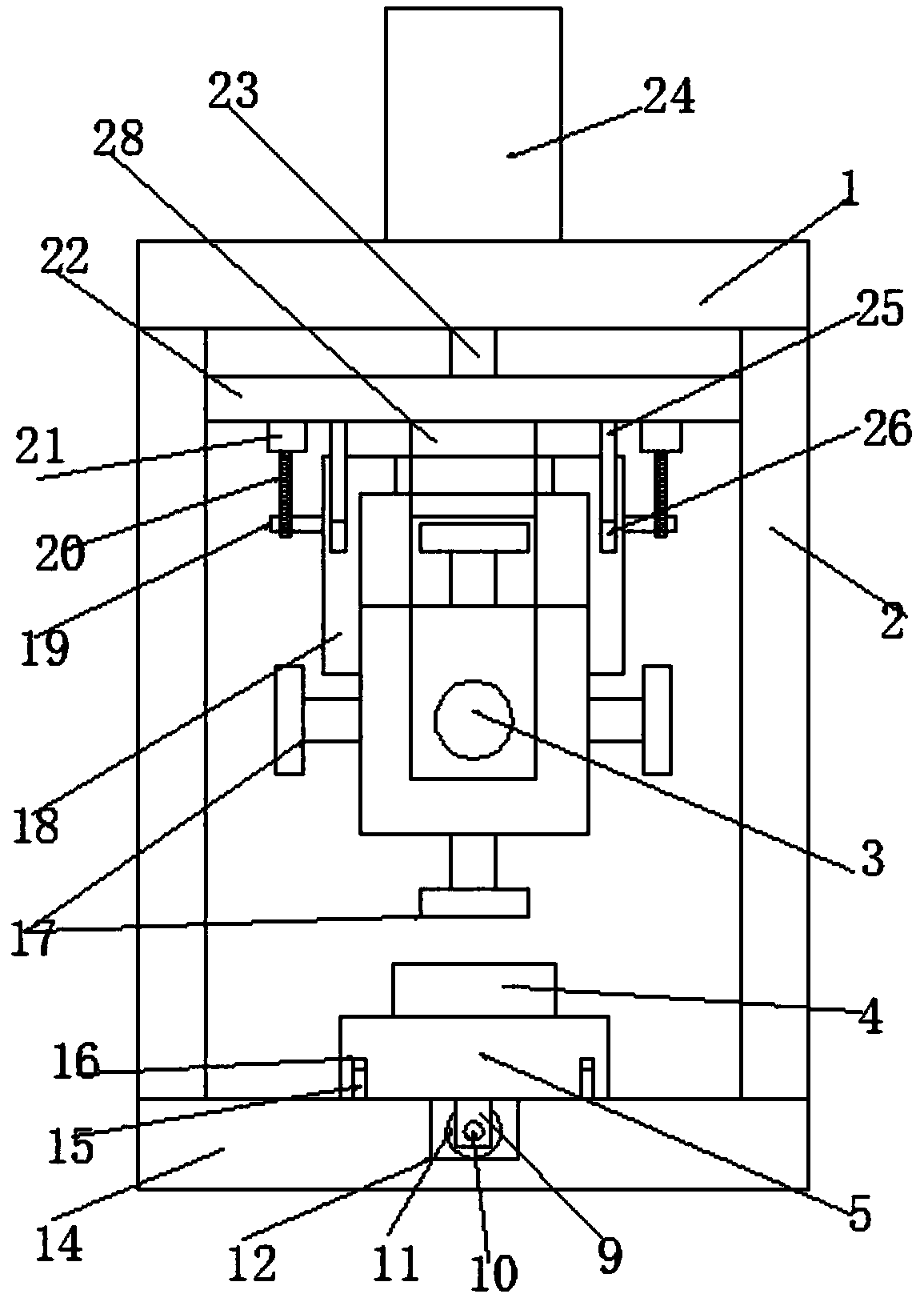

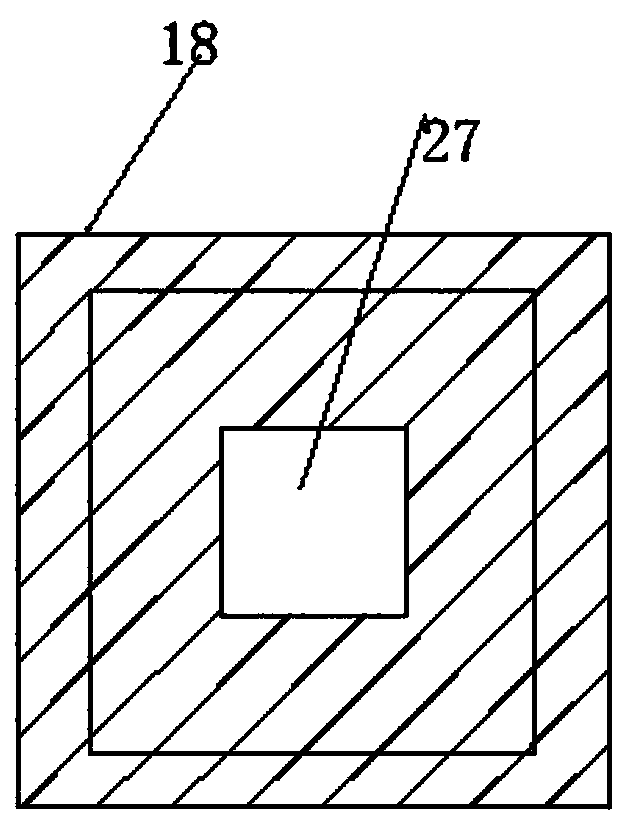

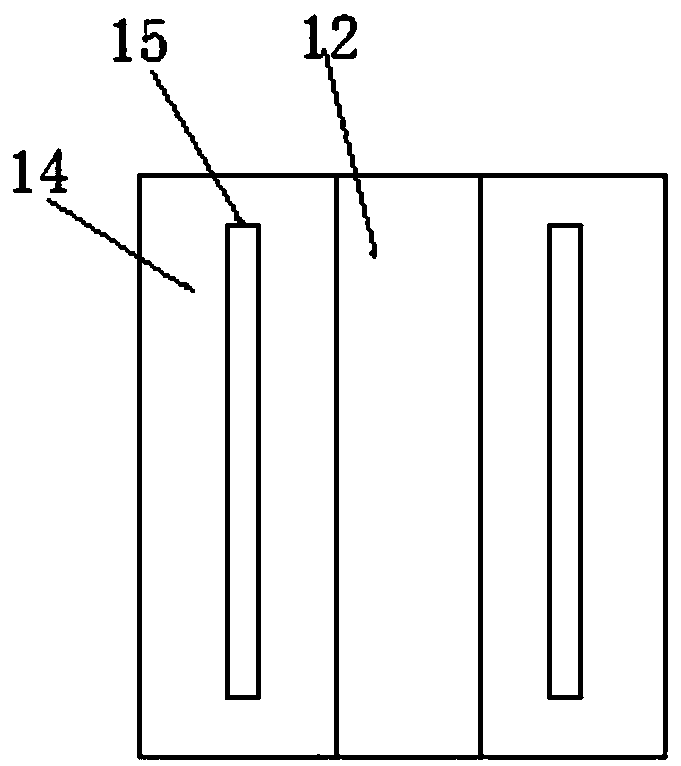

[0023] see Figure 1~4 , in an embodiment of the present invention, a punching machine for bolt processing includes a mounting plate 1 and a processing seat 14, a base 14 is provided under the mounting plate 1, and the support plate 2 and the mounting plate 1 are connected by the support plate 2 on both sides of the upper end of the base 14. The connection is fixed, the middle position of the upper end of the installation plate 1 is provided with a driving hydraulic cylinder 24, the output end of the driving hydraulic cylinder 24 is provided with an output rod 23, and the lower end of the output rod 23 is connected to the lifting slide plate 22, and the left and right ends of the lifting slide plate 22 are connected to the two sides. The support plate 2 is in sliding contact, and the support plate 2 is provided with a lifting chute matched with the lifting slide plate 22. The lower end of the lifting slide plate is symmetrically provided with two hanging plates 28, and a rotati...

Embodiment 2

[0029] see Figure 5 , and the difference from Embodiment 1 is: the buffer seat 13 is provided under the processing seat 14, the support sleeve 7 is symmetrically provided on both sides of the upper end of the buffer seat 13, and the upper end of the support sleeve 7 is slidingly provided with a support leg 6, and the upper end of the support leg 6 is It is connected and fixed with the processing seat 14, and is also connected and fixed by several buffer springs 8 between the buffer seat 13 and the processing seat 14. The setting of this buffer mechanism reduces the impact on the ground when the device is working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com