Feeding, quantitative packing and press-fitting production line for spice

A press-packing production line and material quantification technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problems of increasing labor intensity of workers and low packaging efficiency, so as to reduce labor intensity, improve packaging efficiency, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

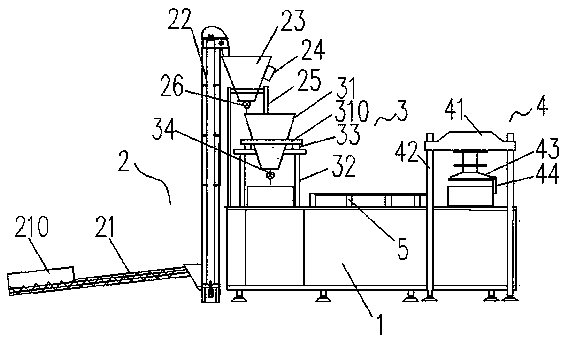

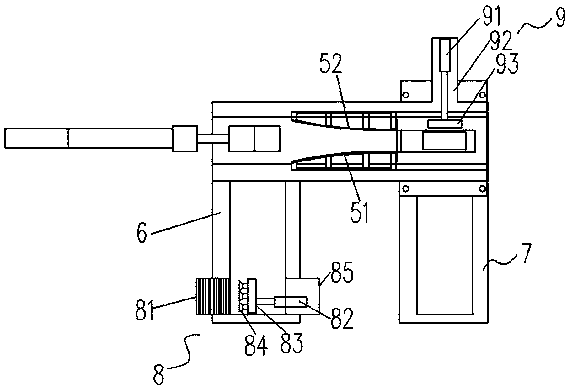

[0025] Example 1, see figure 1 and figure 2 , a quantitative packaging and pressing production line for spice feeding, comprising a first conveyor 1, a feeding device 2, a weighing device 3 and a pressing device 4, and one end of the first conveyor is provided with a feeding device 2 and a weighing device 3. The other end is provided with a pressing device 4; the feeding device includes a transmission auger 21, a hoist 22, a storage bin 23 and a first rotary feeding valve 26; the weighing device 3 includes a skirt 310 The weighing bin 31, weighing bracket 32, weighing module 33 and the second rotary feeding valve 34;

[0026] The inlet end of the conveying auger is provided with a feed bin 210, and the outlet end of the conveying auger 21 is connected with the feed port of the hoist 22, and the upper end outlet of the hoist 22 is communicated with the inlet of the storage bin 23; the first The transmission inlet end of the conveyor 1 is provided with a storage bin installat...

Embodiment 2

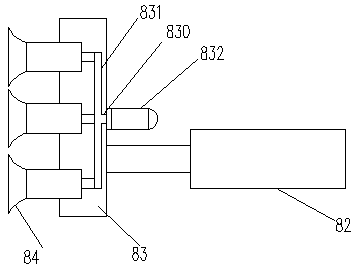

[0036] Example 2: see image 3 — Figure 5 , on the basis of Embodiment 1, the suction cup fixing plate 83 is built with an air passage 831 corresponding to the suction port of each suction cup 84, and a total suction passage 830 is provided in the middle of the outer surface of the suction cup fixing plate 83, and each air passage 831 communicates with total suction passage 830 respectively, and the suction entrance of total suction passage 830 is sealed with trachea quick interface 832, and the suction ports of each suction cup 84 are collected through total suction passage 830 respectively and then through trachea quick interface 832 and Gas generator connection. Adopting the above-mentioned structure can effectively reduce the usage of air pipes, and avoid the lack of suction caused by looseness and air leakage of a single air pipe, which cannot guarantee the unfolding work of the box body.

[0037] Unpacking process:

[0038]First stack the unexpanded carton sideways a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com