A method for reducing the content of suspended particulate matter in qualified bioheap leaching liquid

A technology for suspended particulate matter and qualified liquid, applied in the direction of improving process efficiency, can solve the problems of high labor intensity of workers, decreased extraction rate, low leaching rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

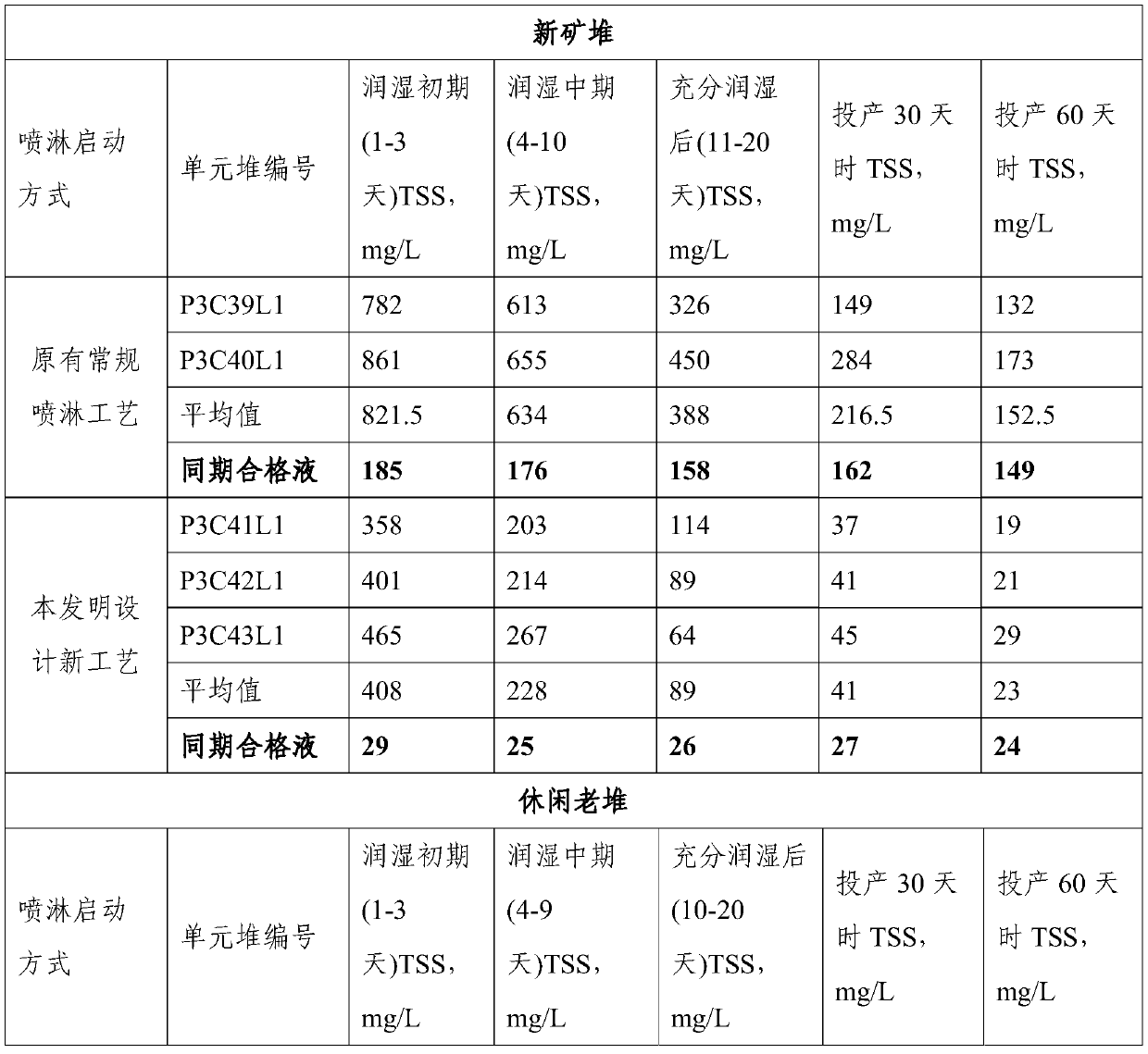

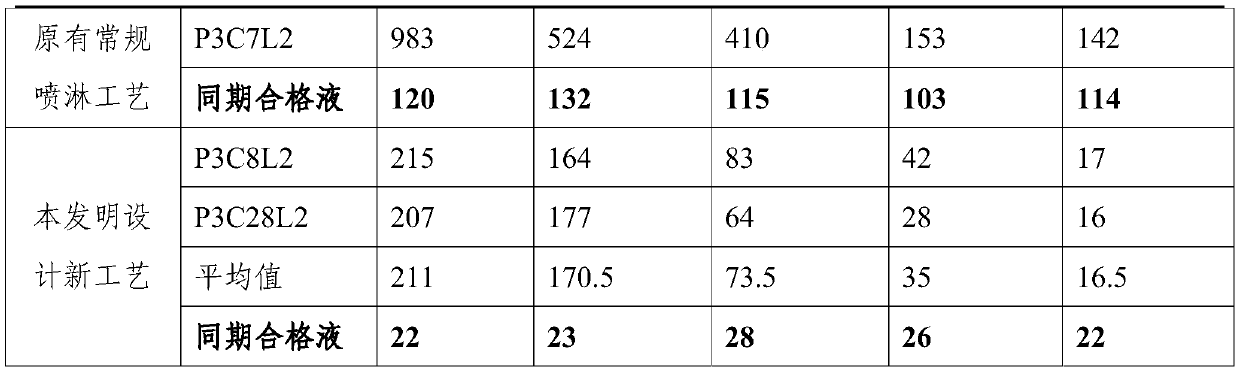

Examples

Embodiment 1

[0014] The main feature of the process method designed by the present invention is that initially, a small flow rate is used to start the solution on the heap, and at the same time, the ore heap is gradually and slowly wetted by means of intermittent spraying and flow rate increase, and the internal gap of the ore heap and the capillary on the surface of the ore are utilized. The effect is to make the solution contact and react with the ore in a gentler way for a long enough time; during the downward flow of the solution, the large particle solids are not easily taken away, and the small particle solids are enriched and deposited intermittently during spraying; After the ore heap is fully wetted, the solution will have a percolation effect. At this time, the intermittent spraying can be changed to continuous spraying. Most of the suspended particles in the solution will be retained in the ore heap under the filtering effect of the ore heap. To achieve the purpose of reducing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com