Erosion-resistant water-cooled spray pipe structure

An anti-scouring and water-cooling technology, which is applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as being easily damaged by ablation, achieve enhanced high-temperature ablation resistance, prolong service life, and ensure success Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

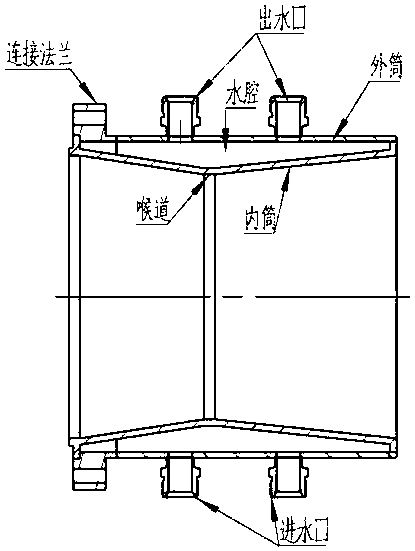

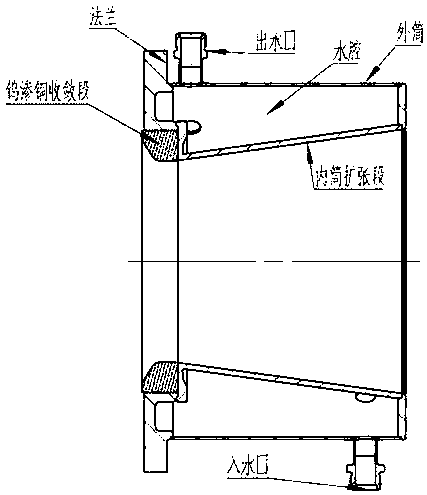

[0013] In order to solve the problems of the prior art, the present invention provides an anti-scouring water-cooled nozzle structure, the water-cooled nozzle structure includes: a flange, an outer cylinder, a convergent section, an inner cylinder expansion section, a water inlet, and a water outlet; figure 2 As shown, in order to reduce the impact of high-temperature and high-speed gas on the erosion and ablation of the convergent section of the water-cooled nozzle, a tungsten-infiltrated copper shell is embedded in the convergent section to replace the stainless steel shell.

[0014] Since the tungsten infiltrated copper material has strong resistance to high-temperature ablation and erosion, the improved water-coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com