Protective demolition method for large oxygen turbine compressor unit

A compressor unit, a protective technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem of lack of protective removal methods for large oxygen turbine compressor units, so as to reduce the cleaning workload and ensure integrity and the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further illustrated below by specific examples.

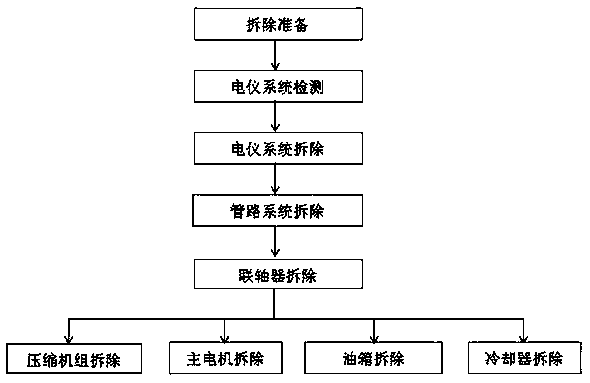

[0015] A method for the protective removal of a large oxygen turbocompressor package comprising

[0016] Step 1. Preparation for dismantling: confirm energy-medium isolation and set up the operation platform. The operation platform is set up on the side of the compressor rotor, and the height is consistent with the height of the compressor foundation;

[0017] Step 2, electrical instrument system detection: including the detection of sensors, local transmitters and connected control lines;

[0018] Step 3. Dismantle the electrical instrument system; when dismantling, first remove the sensor, then dismantle the local transmitter, connect the control line, and the cable tray in sequence;

[0019] Step 4. Piping system removal; including dismantling the cooling water pipe, lubricating oil pipe and instrument air pipe, among which, first remove the cooling water pipe, then remove the lubricating oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com